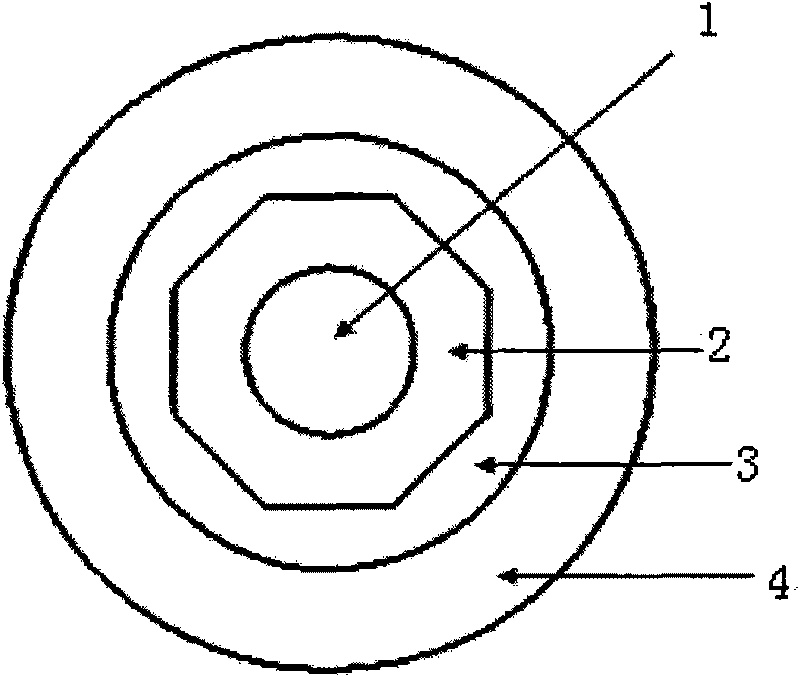

Large-mode active optical fiber and manufacture method thereof

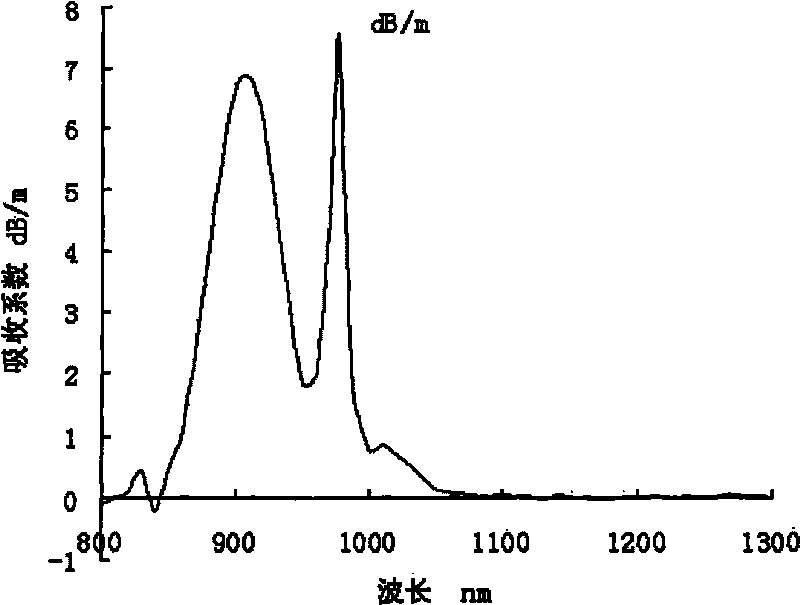

A manufacturing method and large mode field technology, applied in cladding optical fiber, manufacturing tools, glass manufacturing equipment, etc., can solve problems such as poor beam quality, achieve the effects of improving reliability, reducing manufacturing costs, and improving beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment comprises the following steps:

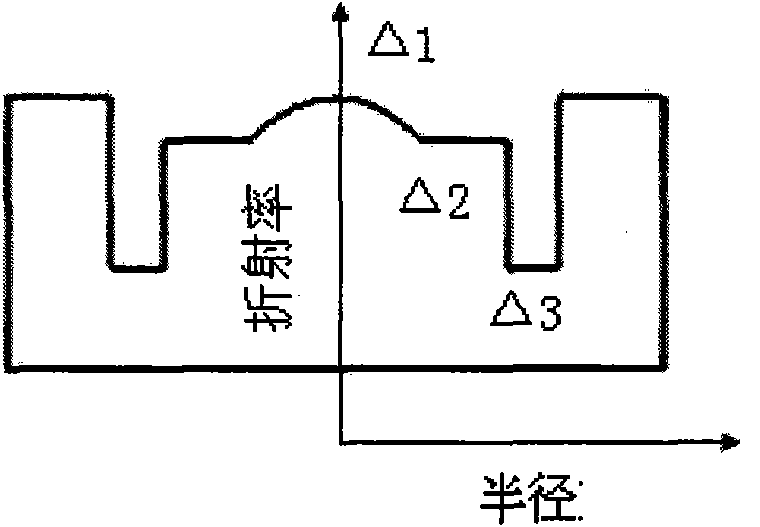

[0046] A10. Use the PCVD plasma chemical vapor deposition process to prepare a fluorine-doped low-refractive index high-purity quartz glass sleeve. The relative refractive index difference of the sleeve material relative to pure quartz glass is -1.06%, that is, use the PCVD process in a hollow Depositing fluorine on the inner wall of the quartz glass substrate tube to obtain a quartz glass casing whose inner wall is a fluorine-doped layer;

[0047] A20, using PCVD plasma chemical vapor deposition process to deposit silicon tetrachloride and germanium tetrachloride on the inner wall of another hollow quartz glass substrate tube to make a preform for drawing the fiber core. In this step, the pressure inside the quartz glass substrate tube is 1000pa to 1200pa, the microwave power for heating the quartz glass substrate tube is 5.0kW to 7.0kW, and the deposition temperature is 1200°C to 1250°C. During the core deposition proce...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that

[0055] In step A10, the relative refractive index difference of the casing material relative to pure quartz glass is -1.50%.

[0056] In step A20, ytterbium ion (Yb 3+ ) with a molar content of 0.12%, and the core refractive index profile distribution parameter α=2.03.

[0057] In step A30, when the diameter of the central hole of the quartz tube is reduced to 1.2mm, it is 100% C 2 f 6 gas, the corrosion time is 10 minutes. After etching, it is melted down into a solid quartz glass core rod. The core diameter of the quartz core rod is 3 mm, and the numerical aperture of the core is 0.05. The relative refractive index difference between the inner cladding of quartz glass and the fluorine-doped low-refractive index sleeve is 1.5%.

[0058] In step A60, the drawn large mode field active optical fiber has a core diameter of 110 μm, an inner cladding diameter of 350 μm, and an outer cladding diameter of ...

Embodiment 3

[0061] The difference between this embodiment and Embodiment 1 is that

[0062] In step A10, the relative refractive index difference of the casing material relative to pure quartz glass is -0.30%.

[0063] In step A20, A1=10.72, B1=0.15, C1=-11.68, α 1 =2.8, ytterbium ion (Yb 3 ) molar content is 0.15%, and the core refractive index profile distribution parameter α=2.86.

[0064] In step A30, when the diameter of the central hole of the quartz tube was reduced to 1.6mm, the concentration of 100% C 2 f 6 Gas, the etching time is 15 minutes, after the etching is completed, it is melted into a solid quartz glass core rod, the core diameter of the quartz core rod is 3.2mm, and the numerical aperture of the core is 0.06.

[0065] In step A40, the solid preform is ground into an inner cladding having a shape of a regular hexagonal prism;

[0066] In step A60, the drawn large mode field active optical fiber has a core diameter of 202 μm, an inner cladding diameter of 655 μm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com