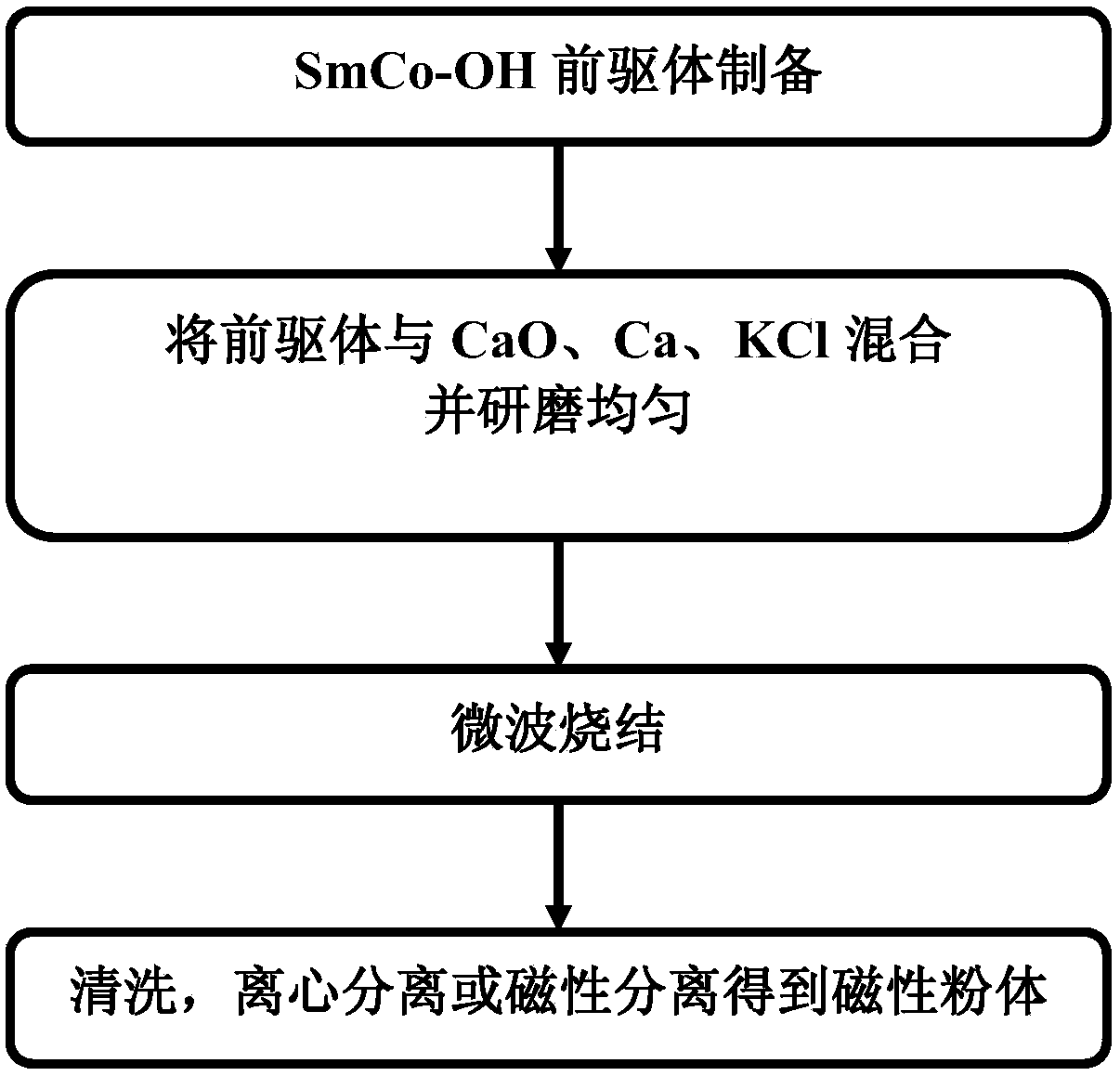

Method for preparing SmCo/ Co nano-composite magnetic material through microwave calcium thermal reduction

A nano-composite and magnetic material technology, which is applied in the manufacture of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of complex process and difficult preparation of magnetic nano-composite materials, and achieves simple process, low cost, and preparation process. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

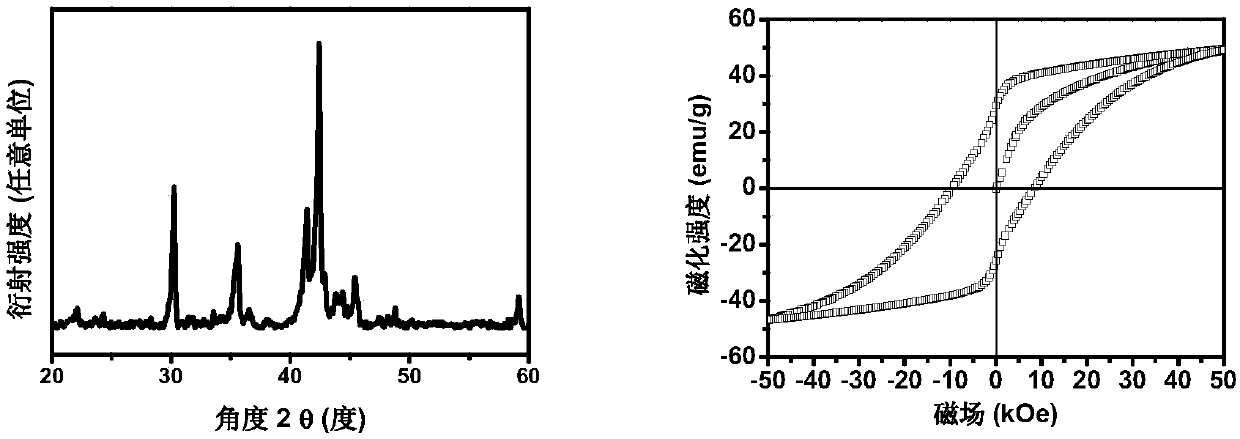

Embodiment 1

[0031] (1) Get a 250mL three-necked flask and place it in an ultrasonic water bath, and add SmCl with a purity of 99% to the three-necked flask 3 ·6H 2 O 0.55 g of CoCl with a purity of 99.99% 2 ·6H 2 O 1.43g, then add 100mL deionized water in the three-necked flask, and mechanically stir for 10 minutes.

[0032] (2) After mechanical stirring for 10 minutes, turn on the ultrasonic instrument, and add 10 mL of 3.5 mol / L NaOH solution into the three-neck flask.

[0033] (3) After reacting for 1 hour, add 150 mL of deionized water to the reaction liquid to dilute the solution, then transfer it to 6 centrifuge tubes, centrifuge at 7500 rpm for 3 minutes, pour off the supernatant and keep the precipitate in the centrifuge tube Add deionized water to the centrifuge tube, ultrasonically clean for 5 minutes, centrifuge at 7500 rpm for 3 minutes, pour off the supernatant and keep the precipitate in the centrifuge tube; then add absolute ethanol to the centrifuge tube, and ultrasonic...

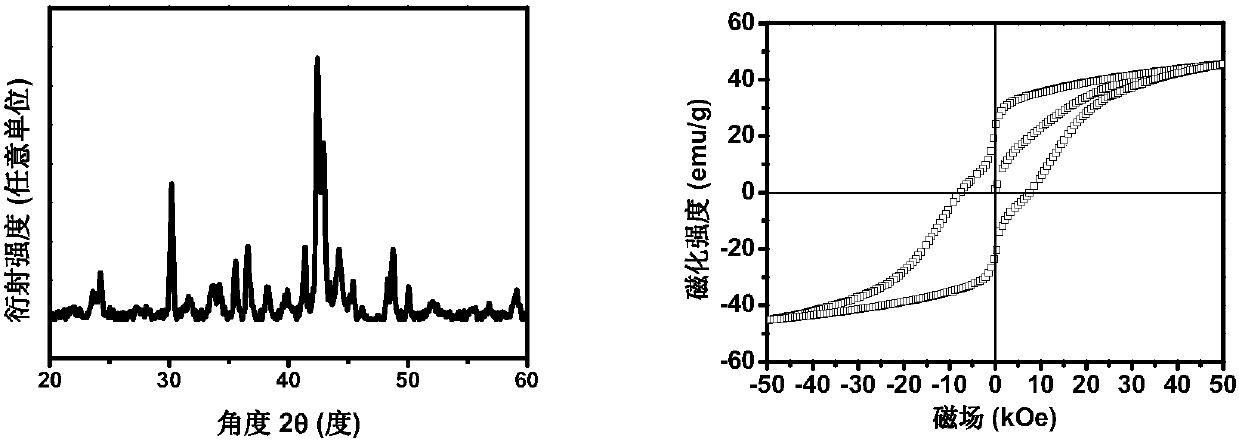

Embodiment 2

[0039] (1) Get a 250mL three-necked flask and place it in an ultrasonic water bath, and add SmCl with a purity of 99% to the three-necked flask 3 ·6H 2 O 0.55 g of CoCl with a purity of 99.99% 2 ·6H 2 O 1.43g, then add 100mL deionized water in the three-necked flask, and mechanically stir for 10 minutes.

[0040] (2) Turn on the ultrasonic device, keep mechanical stirring, and add 10 mL of 3.5 mol / L NaOH solution into the three-necked flask.

[0041] (3) After reacting for 1 hour, add 150 mL of deionized water to the reaction liquid to dilute the solution, then transfer to 6 centrifuge tubes, centrifuge at 7500 rpm for 3 minutes, pour off the supernatant and keep the precipitate in the centrifuge tube Add deionized water to the centrifuge tube, ultrasonically clean for 5 minutes, centrifuge at 7500 rpm for 3 minutes, pour off the supernatant and keep the precipitate in the centrifuge tube; then add absolute ethanol to the centrifuge tube, and ultrasonically clean for five m...

Embodiment 3

[0047] (1) Get a 250mL three-necked flask and place it in an ultrasonic water bath, and add SmCl with a purity of 99% to the three-necked flask 3 ·6H 2 O 0.55 g of CoCl with a purity of 99.99% 2 ·6H 2 O 1.30g, then add 100mL deionized water to the three-necked flask, and mechanically stir for 10 minutes.

[0048] (2) After mechanical stirring for 10 minutes, turn on the ultrasonic instrument, and add 10 mL of 3.5 mol / L NaOH solution into the three-neck flask.

[0049] (3) After reacting for 1 hour, add 150 mL of deionized water to the reaction liquid to dilute the solution, then transfer to 6 centrifuge tubes, centrifuge at 7500 rpm for 3 minutes, pour off the supernatant and keep the precipitate in the centrifuge tube Add deionized water to the centrifuge tube, ultrasonically clean for 5 minutes, centrifuge at 7500 rpm for 3 minutes, pour off the supernatant and keep the precipitate in the centrifuge tube; then add absolute ethanol to the centrifuge tube, and ultrasonicall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Residual magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com