Bicycle frame and manufacturing process thereof

A production process and technology for bicycles, which are applied to bicycle frames, bicycle accessories, transportation and packaging, etc., can solve the problems of high and low frame costs, high labor costs, and high production costs, and achieve short operation time, low labor costs, and production processes. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

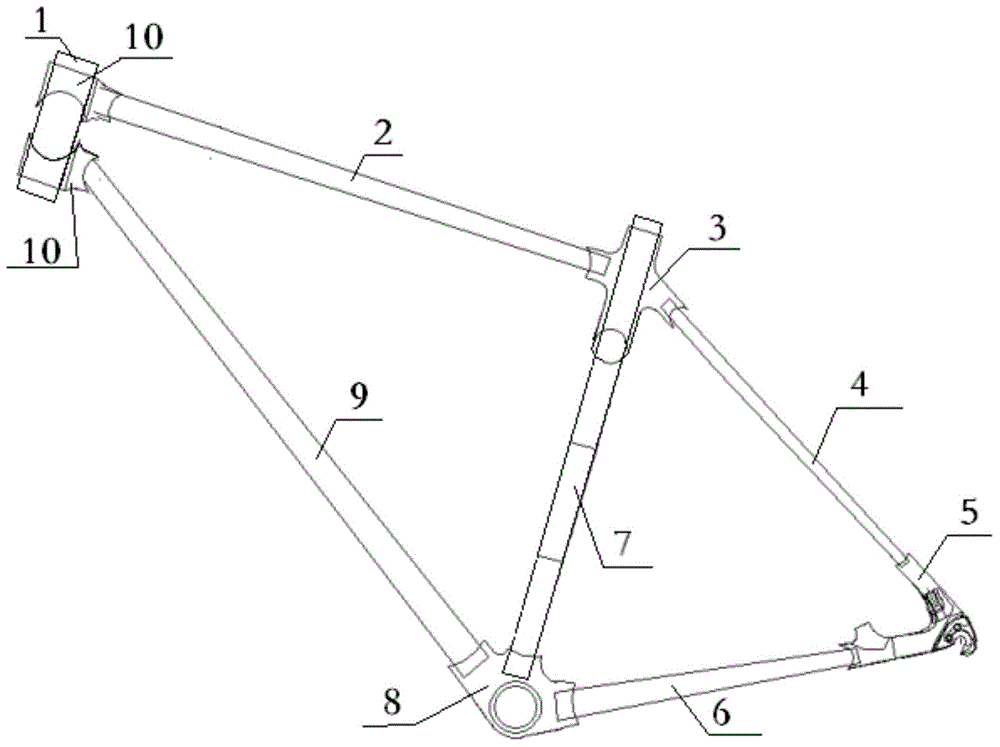

[0028] A bicycle frame, comprising a hollow tube and metal connectors, the metal connectors are respectively a bottom bracket connector 8, a dropout connector 5, a seat tube connector 3 and two front connectors 10, the hollow The tubes are respectively the front tube 1, the upper tube 2, the middle tube 7, the lower tube 9, the upper fork 4 and the lower fork 6; A front connecting piece 10 is connected with the lower tube 9, the upper tube 2, the middle tube 7 and the upper fork 4 are connected through the seat tube connecting piece 3, and the lower tube 9, the middle tube 7 and the lower fork 6 are connected through the bottom bracket 8, the upper fork 4 and the lower fork 6 are connected through the dropout connector 5, the front connector 10 is a three-way connector, and the seat tube connector 3 is a four-way connector; the hollow tube Glued together with metal connectors to form a frame body.

[0029] Hollow pipes are carbon fiber pipe fittings, glass fiber pipe fittings...

Embodiment 2

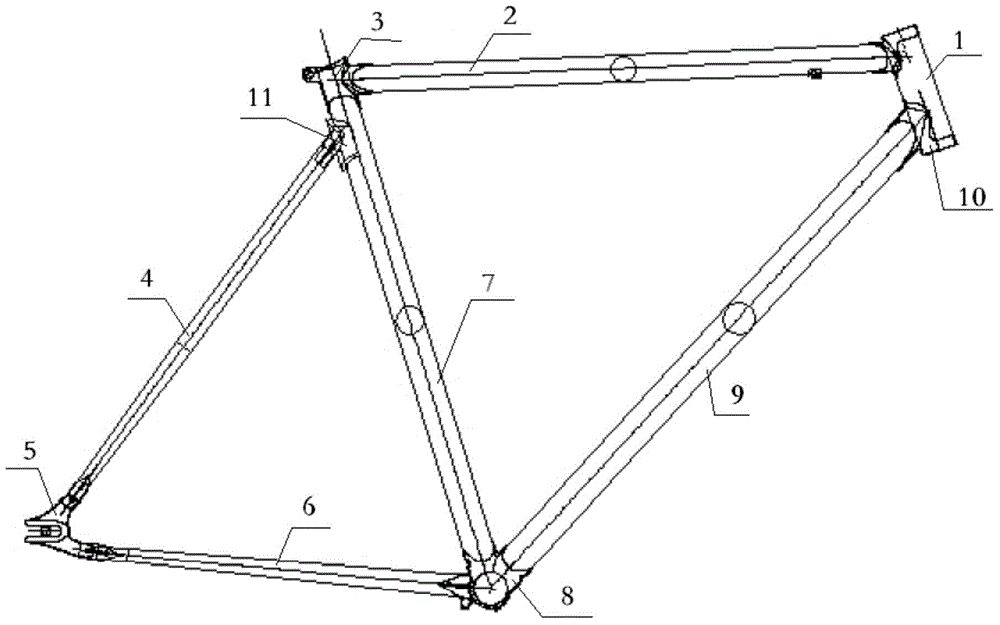

[0032] A bicycle frame, comprising a hollow tube and metal connectors, the metal connectors are respectively a bottom bracket connector 8, a dropout connector 5, a seat tube connector 3, a seat stay connector 11 and two bike fronts Connector 10, the hollow tubes are respectively the front 1, the upper tube 2, the middle tube 7, the lower tube 9, the upper fork 4 and the lower fork 6; the front 1 is connected to the upper tube 2 through a front connector 10 , the front 1 is connected to the lower tube 9 through a front connector 10, the upper tube 2 and the middle tube 7 are connected through the seat tube connector 3, and the middle tube 7 is connected to the upper fork 4 through the seat stay The lower tube 9, the middle tube 7 and the lower fork 6 are connected by a bottom bracket 8, the upper fork 4 and the lower fork 6 are connected by a hook, and the front connector 10 is a tee , the seat tube connector 3 is a three-way connector; the hollow tube and the metal connector a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com