Fish meat emulsion fermented with mixed bacteria based on lactobacillus and preparation method thereof

A technology of mixing bacterial strains and minced fish, which is applied in food preparation, application, food science, etc., can solve the problems of not being able to better inhibit spoilage microorganisms, it is difficult to ensure the hygiene and safety of products, and the fishy smell is not completely removed, so as to achieve a rich hand feeling. Flexible, easy to operate, easy to cultivate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

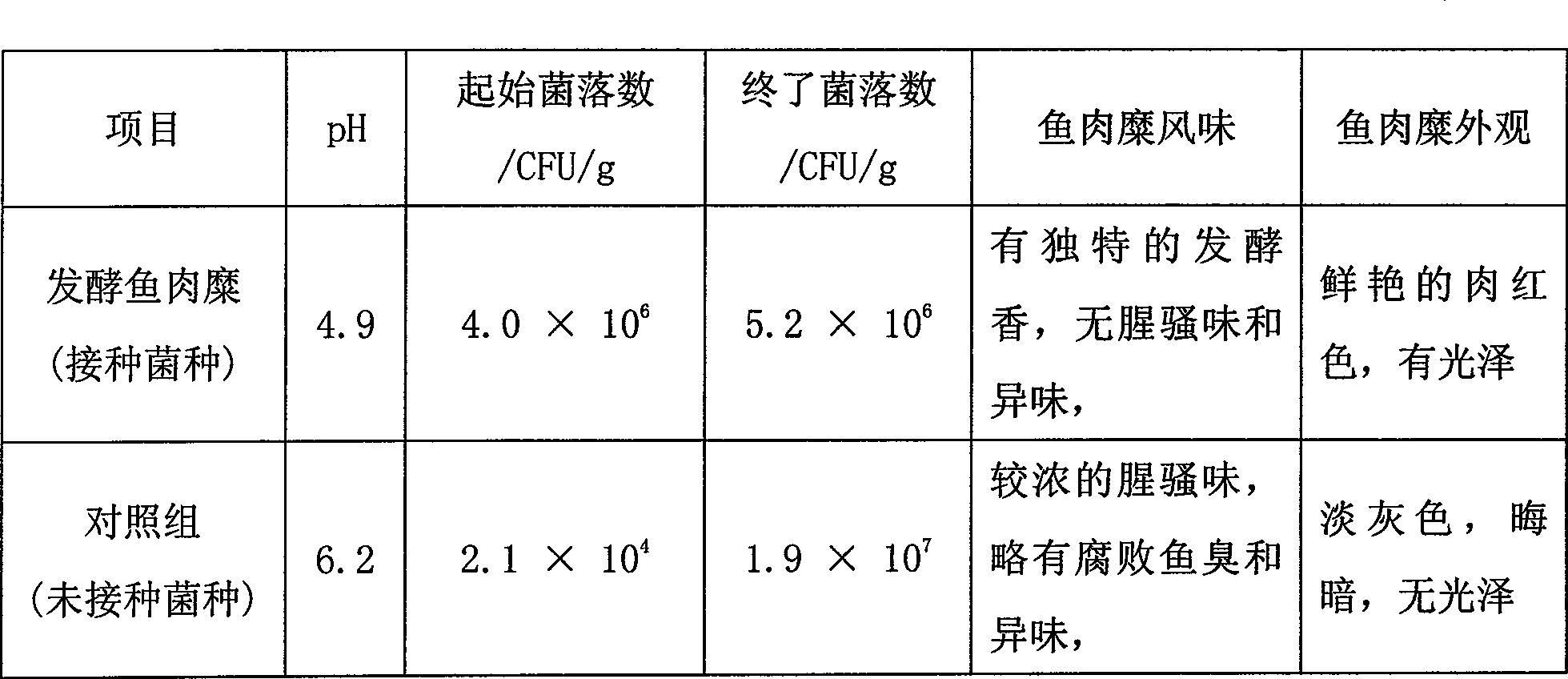

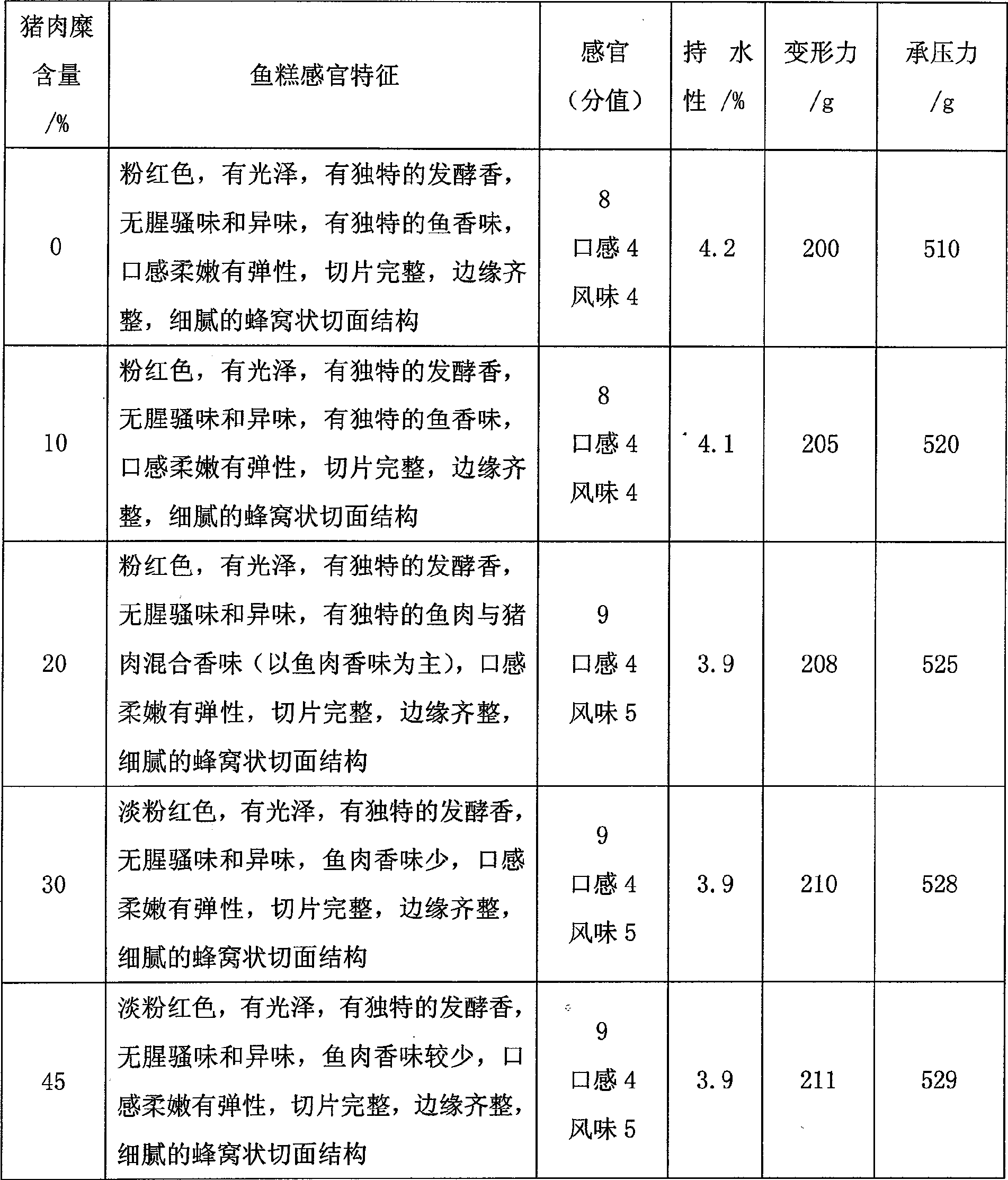

[0052] A minced fish fermented based on a mixed strain of lactic acid bacteria, which uses minced fish as a base material, and the number of inoculated colonies reaches 10 for each strain 6 CFU / g minced fish cultured by Streptococcus lactis, Lactobacillus bulgaricus and Saccharomyces cerevisiae as type I mixed base bacteria and the number of inoculated colonies is 10 6 spores / g minced fish is cultivated by Monascus bacterium as type II mixed base bacteria, the minced fish inoculated with the initial culture is placed in a container and fermented until the acidity of the minced fish reaches the standard, then the filler is mixed and added, and then vacuum degassed to prepare , package, and obtain a finished product.

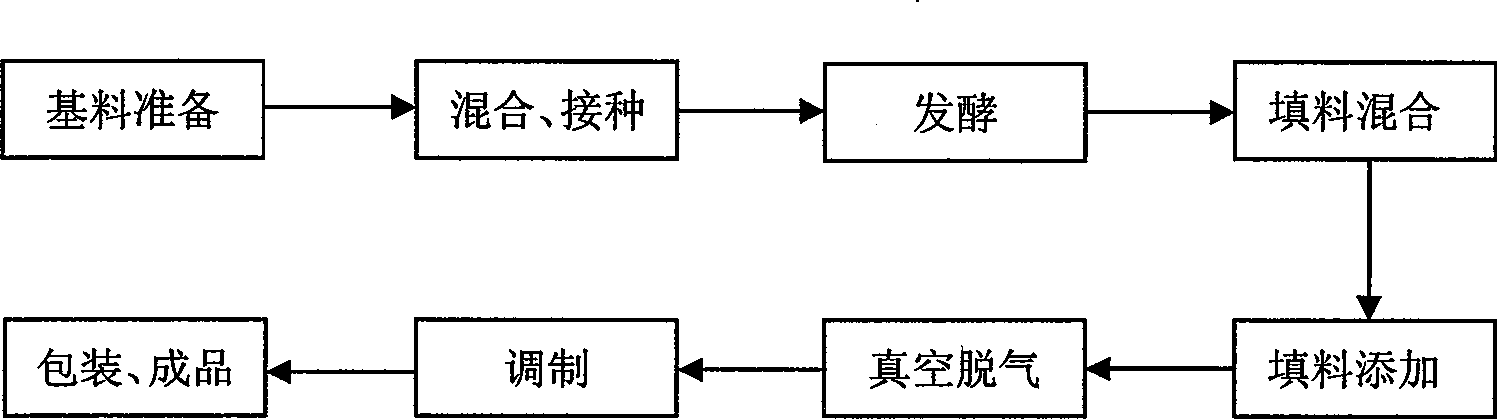

[0053] The technical process and specific operation steps for preparing minced fish meat fermented by mixed strains of lactic acid bacteria are as follows:

[0054] I. Process flow

[0055] Base material preparation-mixing, inoculation-fermentation-filler mixin...

Embodiment 2

[0078] A minced fish fermented based on a mixed strain of lactic acid bacteria, which uses minced fish as a base material, and the number of inoculated colonies reaches 10 for each strain 6 CFU / g minced fish cultured by Streptococcus lactis, Lactobacillus bulgaricus and Saccharomyces cerevisiae as type I mixed base bacteria and the number of inoculated colonies is 10 6 spores / g minced fish is cultivated by Monascus bacterium as type II mixed base bacteria, the minced fish inoculated with the initial culture is placed in a container and fermented until the acidity of the minced fish reaches the standard, then the filler is mixed and added, and then vacuum degassed to prepare , package, and obtain a finished product.

[0079] The technical process and specific operation steps for preparing minced fish meat fermented by mixed strains of lactic acid bacteria are as follows:

[0080] I. Process flow

[0081] Base material preparation-mixing, inoculation-fermentation-filler mixin...

Embodiment 3

[0104] A minced fish fermented based on a mixed strain of lactic acid bacteria, which uses minced fish as a base material, and the number of inoculated colonies reaches 10 for each strain 6 CFU / g minced fish cultured by Streptococcus lactis, Lactobacillus bulgaricus and Saccharomyces cerevisiae as type I mixed base bacteria and the number of inoculated colonies is 10 6 spores / g minced fish is cultivated by Monascus bacterium as type II mixed base bacteria, the minced fish inoculated with the initial culture is placed in a container and fermented until the acidity of the minced fish reaches the standard, then the filler is mixed and added, and then vacuum degassed to prepare , package, and obtain a finished product.

[0105] The technical process and specific operation steps for preparing minced fish meat fermented by mixed strains of lactic acid bacteria are as follows:

[0106] I. Process flow

[0107] Base material preparation-mixing, inoculation-fermentation-filler mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com