Safety environment-friendly fuel and preparation technology thereof

A safe, environmentally friendly and preparation technology, applied in the fuel, solid fuel, petroleum industry and other directions, can solve the problems of low utilization rate of combustible waste, dust pollution, air and water environment pollution, etc., to solve the problem of resource utilization, reduce Effect of dust, good gelling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

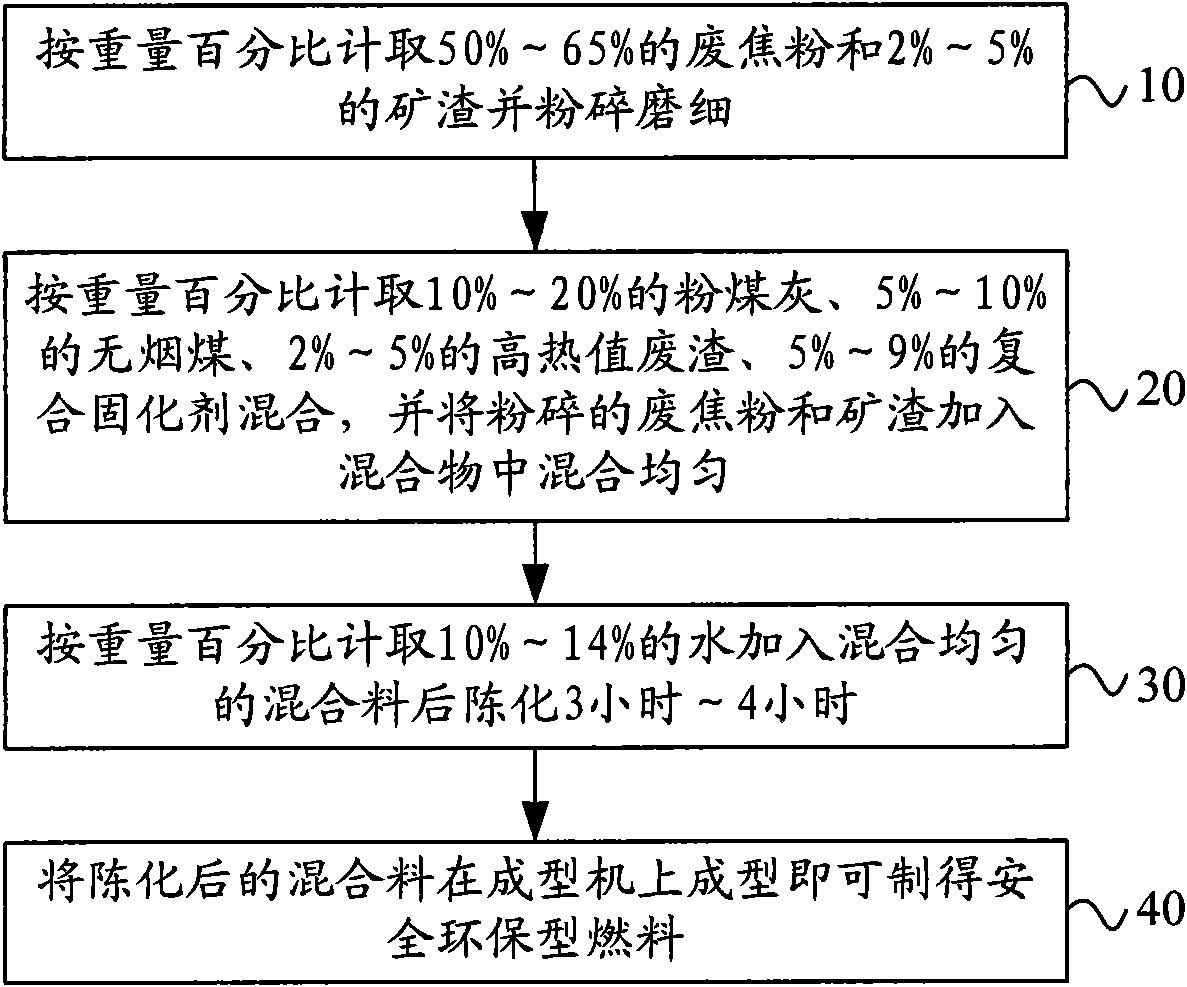

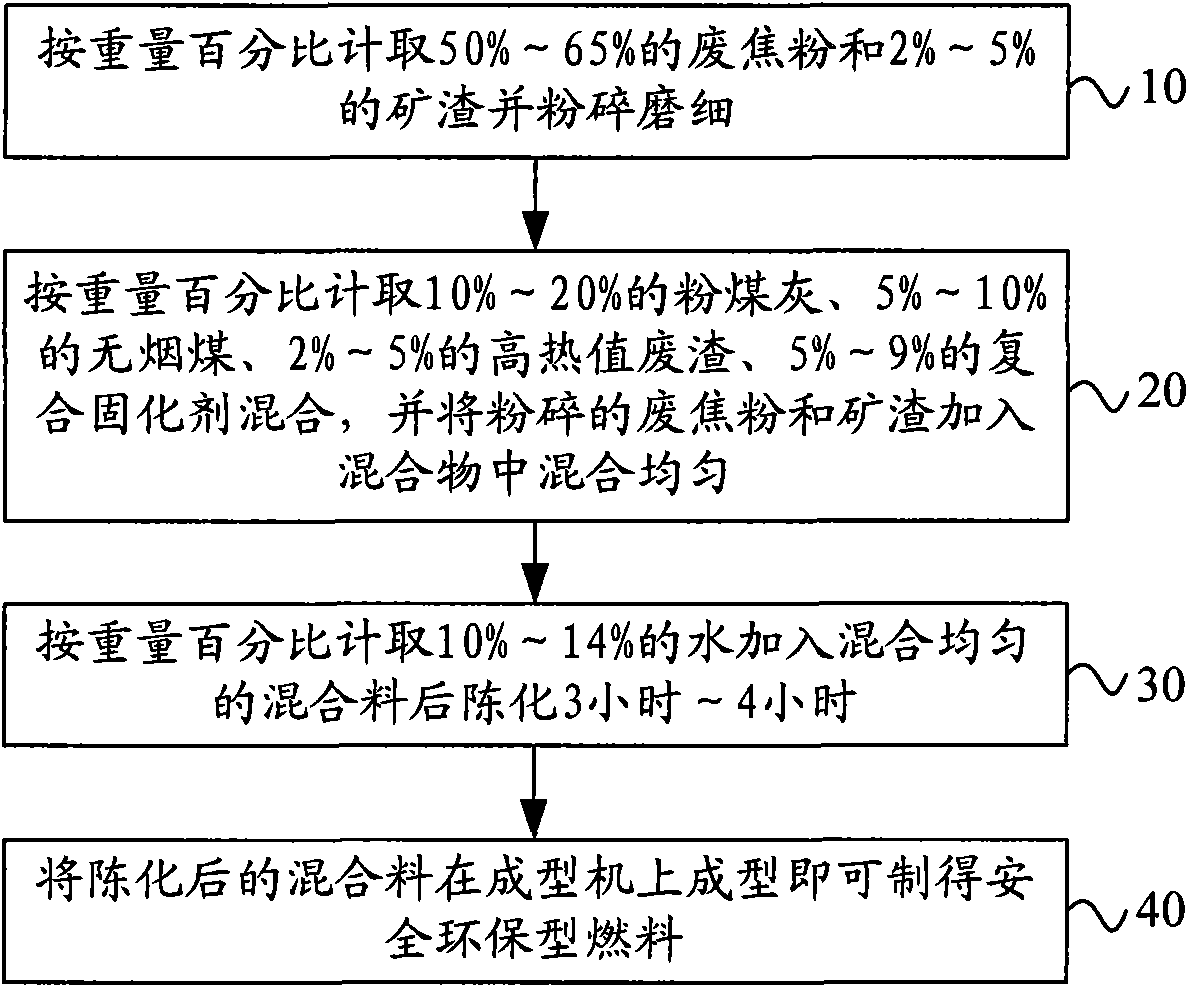

[0023] figure 1 It is a schematic flow chart of the preparation process of the safe and environment-friendly fuel of the present invention. like figure 1 As shown, the preparation process includes the following steps:

[0024] Step 10, taking 50%-65% of waste coke powder and 2%-5% of slag by weight percentage and crushing and grinding them finely.

[0025] The waste coke powder is crushed and ground until 2%-10% pass through a 100-mesh sieve, and the slag is crushed and ground until 1%-4% passes through a 180-mesh sieve. The finer the particle size of the waste coke powder, the larger the surface area and contact area, which increases the cohesion and improves the compressive strength of the fuel after molding. However, if the particle size is too fine, the processing cost will be increased. The particle size of fly ash is generally finer, so it can not be processed. The test results show that the optimum fineness of waste coke powder is 80 mesh.

[0026] Step 20, take 1...

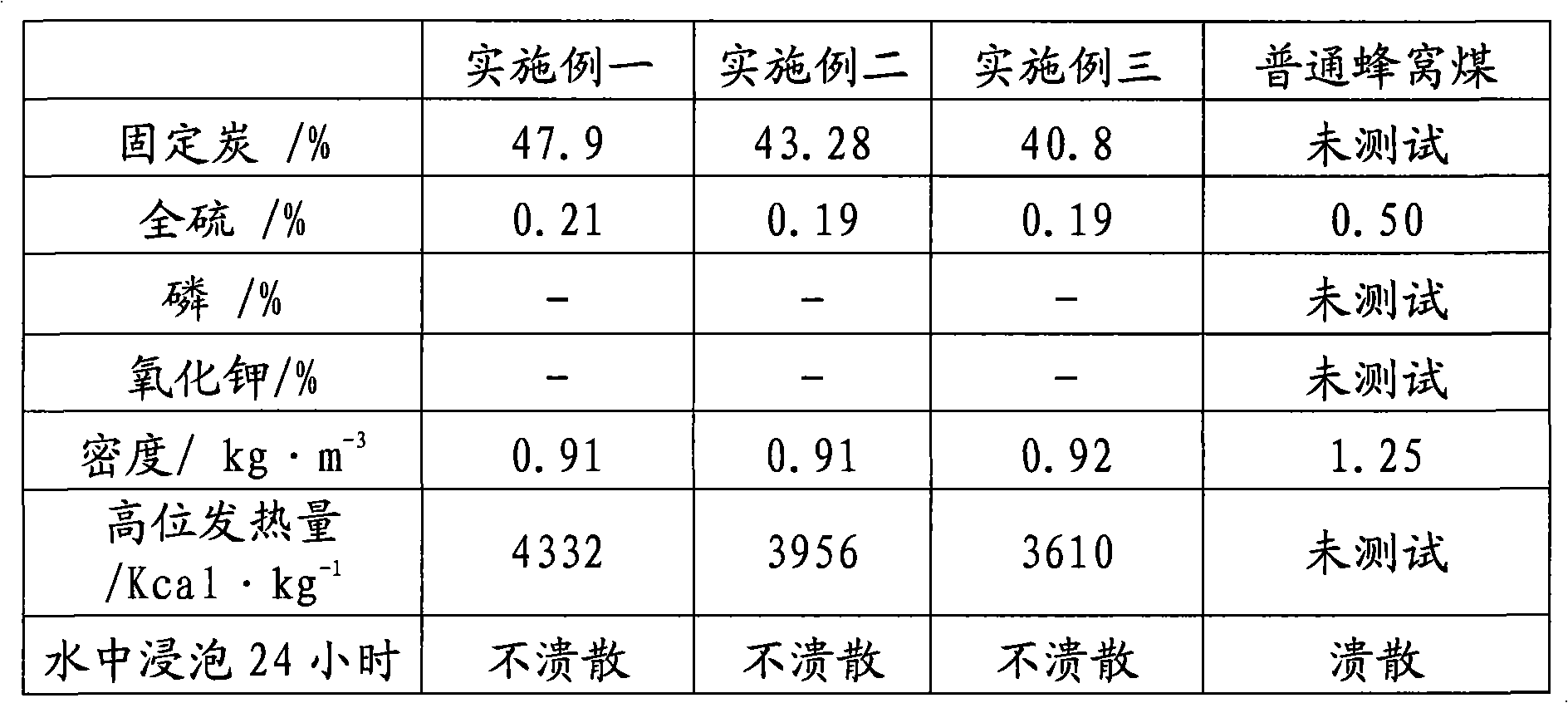

Embodiment 1

[0038] First, take 50 kilograms of straw and crush it until the particle size is less than 1 mm, and set it aside; then, take 540 kilograms of waste coke powder and 50 kilograms of slag and grind them finely; then, take 200 kilograms of fly ash, 50 kilograms of anthracite, 70 kilograms of composite solidifying agent are mixed, and pulverized waste coke powder, slag and straw are added to the mixture and mixed uniformly, wherein the composite solidifying agent includes 40 kilograms of slaked lime, 20 kilograms of potassium silicate and 10 kilograms of potassium sulfate; then, Take 130 kg of water and add it to the homogeneous mixture and age it for 3 hours; finally, mold the aged mixture on a molding machine to produce a safe and environment-friendly fuel.

Embodiment 2

[0040]First, take 35 kilograms of straw and crush it until the particle size is less than 1 mm, and set it aside; then, take 500 kilograms of waste coke powder and 50 kilograms of slag and grind them finely; then, take 200 kilograms of fly ash, 50 kilograms of anthracite, 70 kilograms of composite solidifying agent are mixed, and pulverized waste coke powder, slag and straw are added to the mixture and mixed uniformly, wherein the composite solidifying agent includes 40 kilograms of slaked lime, 20 kilograms of potassium silicate and 10 kilograms of potassium sulfate; then, Take 120 kg of water and add it to the homogeneous mixture and age it for 3 hours; finally, mold the aged mixture on a molding machine to produce a safe and environment-friendly fuel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com