Three-dimensional luminous light emitting diode (LED) lamp bulb module and manufacturing method thereof

A technology of LED light bulbs and modules, which is applied to semiconductor devices, light sources, electric light sources, etc. The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

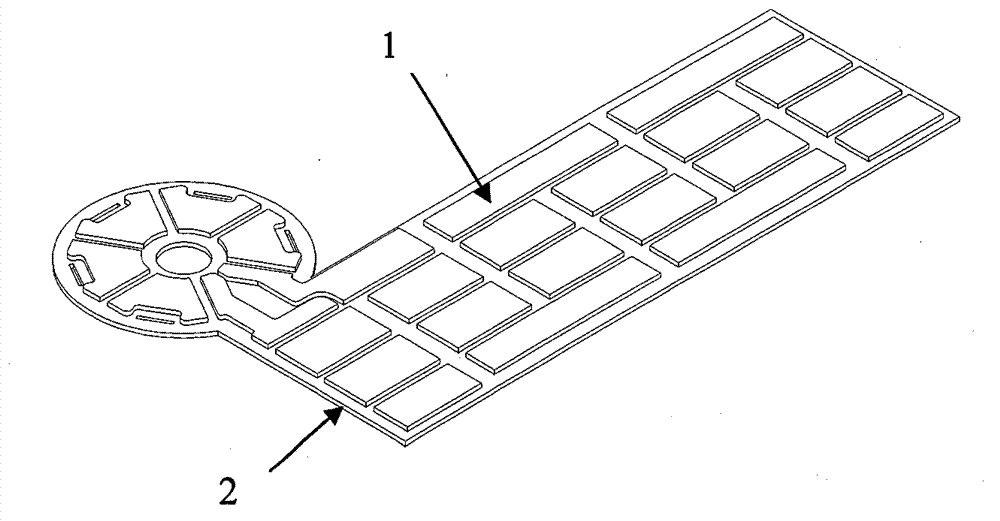

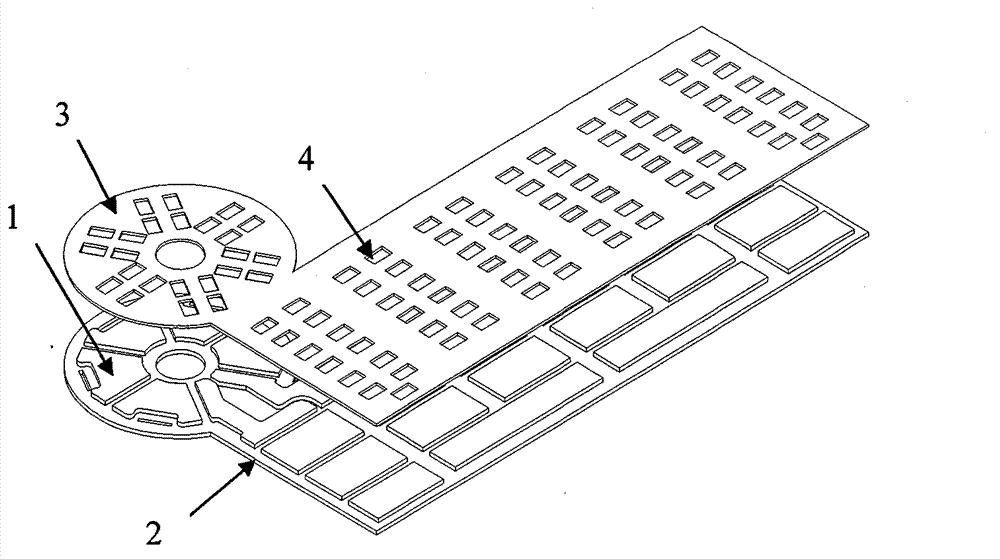

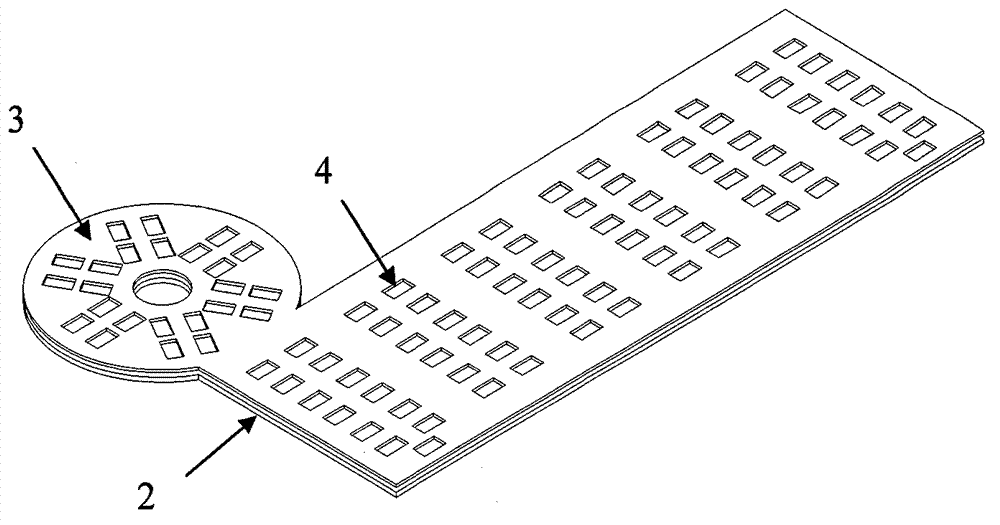

[0029] A specific embodiment of a new three-dimensional light-emitting LED light bulb module of the present invention will be described in more detail below.

[0030] However, those skilled in the art should understand that these implementation modes are only some specific examples of the present invention, and do not limit the present invention and its protection scope in any way.

[0031] For example, the configuration of the circuit board is not limited to the configuration shown in the following specific embodiments. Those of ordinary skill in the art can carry out some obvious changes and modifications on the condition of understanding the basic idea of the present invention, and these all belong to the scope of the present invention. The scope of the present invention is limited only by the claims.

[0032] In the present invention, "flexible and rigid circuit board" refers to a composite circuit board formed by pasting a rigid reinforcing sheet on a traditional flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com