3D printing method for high-performance foam shoe midsole

A 3D printing, high-performance technology, applied in the field of footwear manufacturing, can solve the problems affecting the dimensional stability of footwear products, complex process, low efficiency, etc., and achieve the effect of personalized customization, short preparation process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

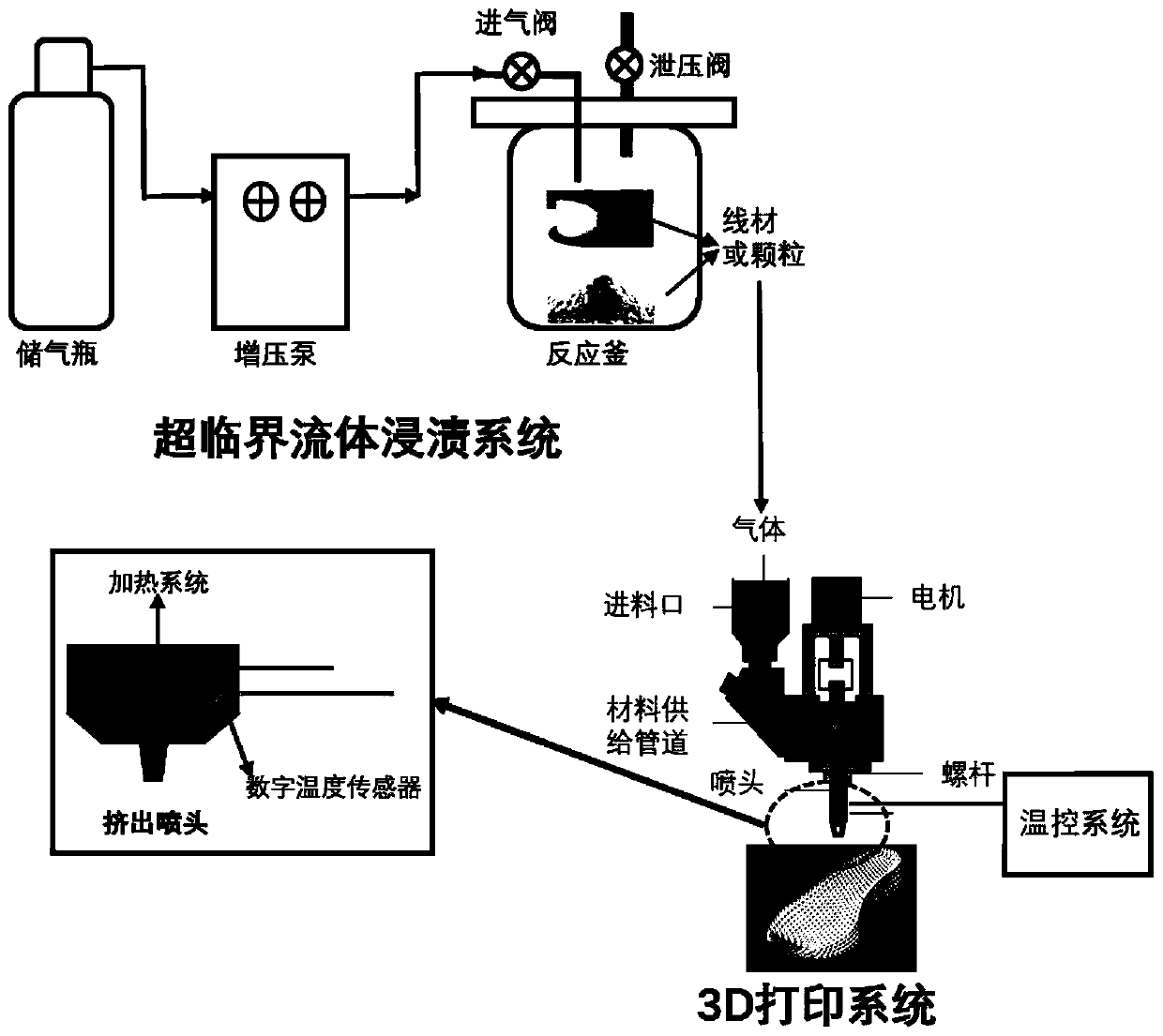

Method used

Image

Examples

Embodiment 1

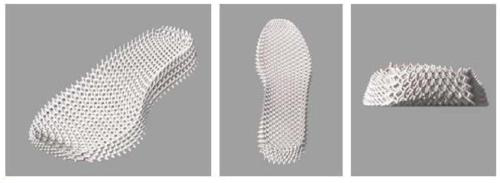

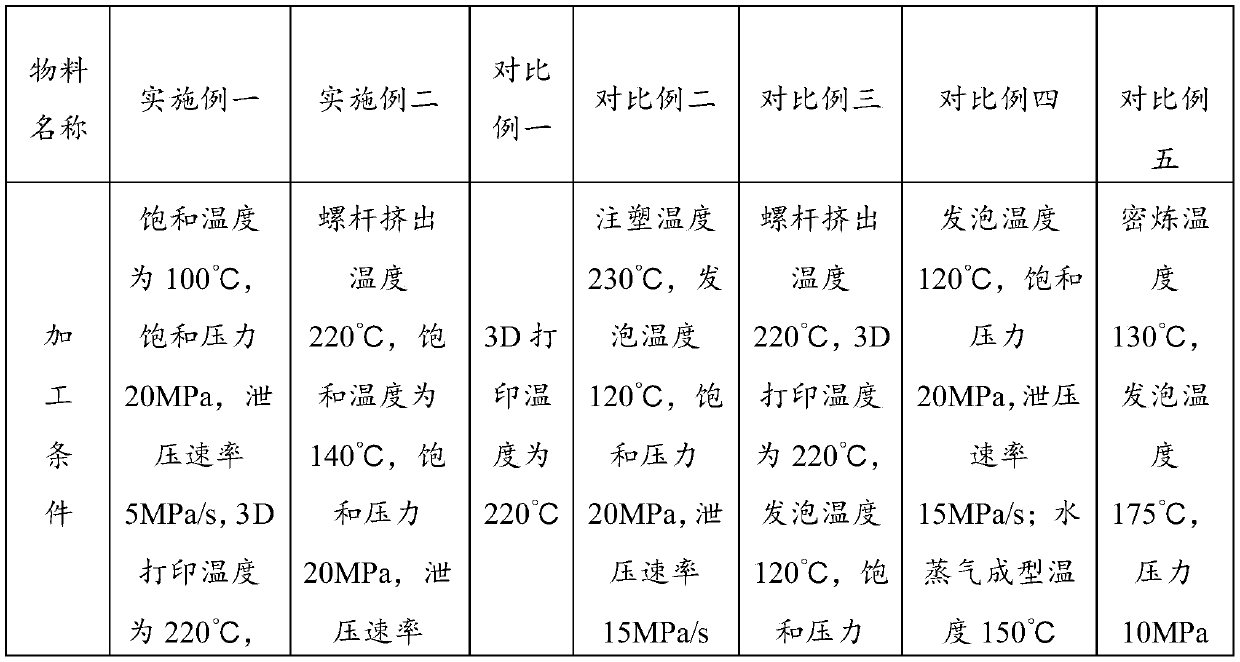

[0041] Thermoplastic polyurethane elastomer particle (Estane 58315 TPU of Lubrizol company) is put into autoclave after drying, feeds nitrogen, is heated up to 100 ℃, pressurizes to 20MPa, to reach supercritical state, to described elastomer particle The material is saturated, and after 2 hours, the pressure is released and taken out at a pressure release rate of 5MPa / s; the saturated resin particles are put into the screw extrusion 3D printer through the hopper, and the temperature of the printer cavity is set to 220°C. The temperature was set at 140°C. The diameter of the die mouth is 1.0mm; the diameter of the cavity with the temperature control device at the die mouth is 0.8mm. according to figure 2 The 3D digital model of the midsole shown is 3D printed by fusion deposition to obtain the foamed sports shoe midsole.

[0042] The structure of the midsole of the foamed sports shoes is as follows: figure 2 As shown, the size of the midsole is US9.5 (the thickness of the ...

Embodiment 2

[0044] Thermoplastic polyurethane elastomer particles (Elastollan 1175A10W TPU of BASF Company) were dried and added into the barrel of a twin-screw extruder, melted and mixed at a temperature of 220°C, and extruded to obtain a printing wire (the diameter of the wire is 1.75 mm).

[0045] Put the wire into the autoclave, feed nitrogen, raise the temperature to 140°C, pressurize to 20MPa to reach the supercritical state, saturate the elastomer wire, take it out after 2 hours, and release the pressure The speed is 5MPa / s; the saturated resin wire is put into the screw extrusion 3D printer through the feed port, the temperature of the printer cavity is set to 220°C, and the temperature at the nozzle is set to 140°C. according to figure 2 The three-dimensional digital model of the midsole shown is 3D printed by fusion deposition to obtain the midsole of foamed sports shoes (the specifications are the same as in Example 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com