Chip scale packaged MEMS (Micro-Electro-Mechanical Systems) chip with multifunctional cover board and manufacturing method of chip scale packaged MEMS chip with multifunctional cover board

A technology of chip-level packaging and manufacturing methods, which is applied in the direction of manufacturing tools, manufacturing microstructure devices, and photolithography on patterned surfaces. It can solve the problems of no signal lines, etc., and achieve the reduction of the number of masks and the stability of real-time leak detection. , the effect of strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

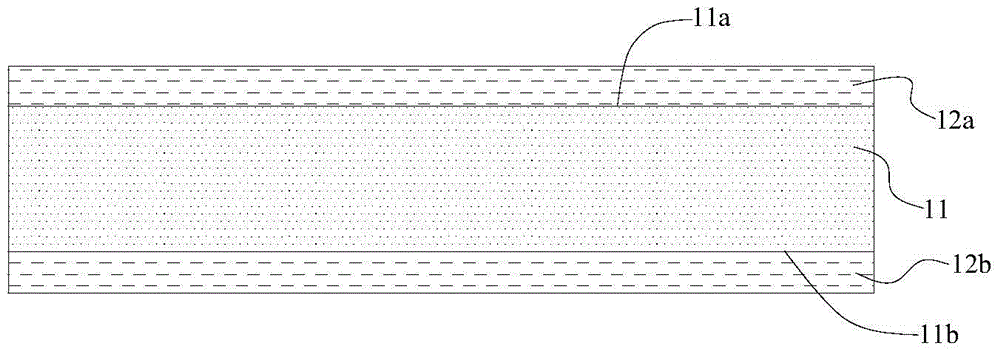

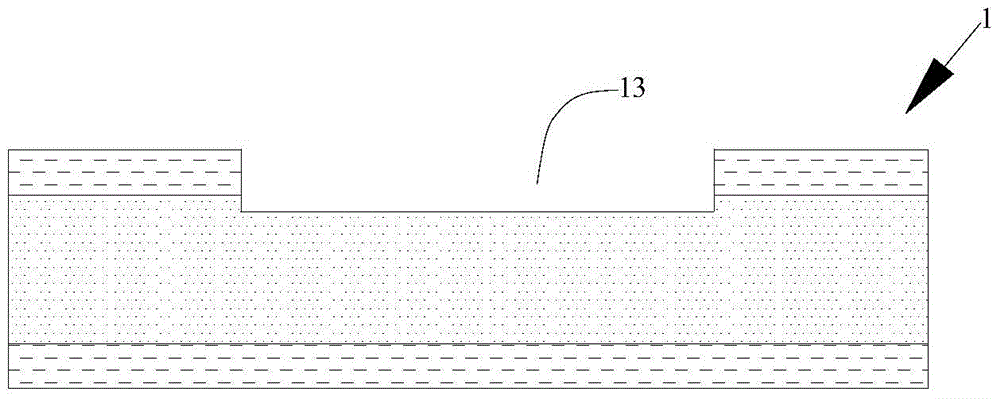

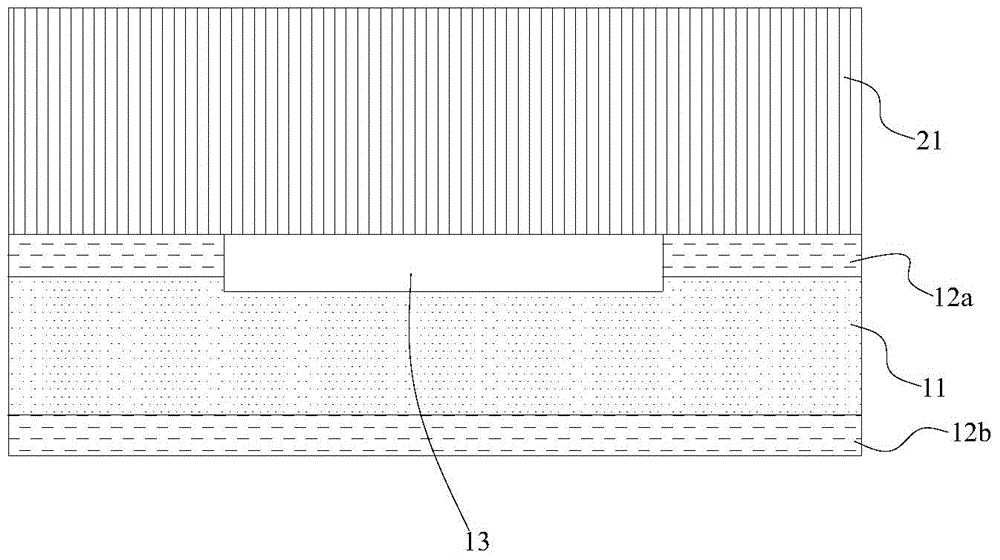

[0046] The MEMS chip 5 of the chip-scale package with multifunctional cover plate of the present embodiment, as Figure 13 As shown, the base substrate 11 comprising a cover plate 30, a MEMS structure layer 22 and at least one lower cavity 13, the area of the cover plate 30 is smaller than the area of the base substrate 11, and the material of the base substrate 11 is crystal oriented heavily doped single crystal silicon, the depth of the lower concave cavity 13 is 5-30 μm, the base substrate 11 has an upper base insulating layer 12a, the material of the upper base insulating layer 12a is silicon dioxide, and the thickness is 0.5-3 μm, The upper base insulating layer 12a is used for bonding the MEMS structure layer 22, providing mechanical support and electrical isolation; the material of the MEMS structure layer 22 is heavily doped single crystal silicon with a crystal orientation, and the MEMS structure layer 22 includes the MEMS structure 22a, The gap 22b and the MEMS...

Embodiment 2

[0069] The cover plate 30 of the chip-scale packaged MEMS chip 5 with the multifunctional cover plate of the present embodiment is used as a constant temperature heater to heat the MEMS chip at a constant temperature: the first metal layer pattern 33 is used as a constant temperature heating resistor 33a, and the constant temperature heating resistor 33a is evenly distributed On the cover plate 30, during subsequent packaging, one end of the constant temperature heating resistor 33a is connected to the seventh ASIC pad 607, and the other end is connected to the fourth ASIC pad 604, as Figure 17 As shown, the power flowing through the constant temperature heating resistor 33a is controlled by the ASIC chip 6. In order to achieve the purpose of constant temperature heating, a thermistor must be provided to feed back the temperature signal. The thermistor is also made of the first metal layer pattern 33. The electrical signal of the resistor is connected to the first ASIC pressur...

Embodiment 3

[0071] For making the thermal convection accelerometer that leak detection is used on cover plate 30, in Figure 12On the cover wafer 3 of the chip-scale packaged MEMS wafer 4 with a multifunctional cover plate shown, an accelerometer pattern is formed by photolithography, an anisotropic etching of the intermetallic insulating layer 34 and an upper cover insulating layer 32a, each Isotropic deep Si etching cover plate substrate 31, deglue, dig out leak detection cavity 82 on the heat convection accelerometer area 81 of cover plate wafer 3, make it into the MEMS wafer for leak detection; In the case of meter area 81, the MEMS wafer for leak detection is cut into a plurality of MEMS chips 8 for leak detection by a method similar to embodiment 1, see Figure 18 .

[0072] Figure 19 The middle heat convection accelerometer area 81 is located at the central position of the cover plate 30. The purpose is to facilitate the protection of the heat convection accelerometer when the M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com