P-type CuxSy semiconductor nanocrystalline, preparation method and application thereof

A nanocrystal and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor device, nanotechnology, etc., can solve the problem of single crystal phase, and achieve the effect of single crystal phase, good electrical conductivity, and high carrier mobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

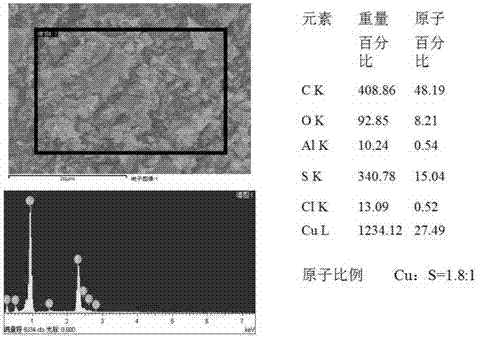

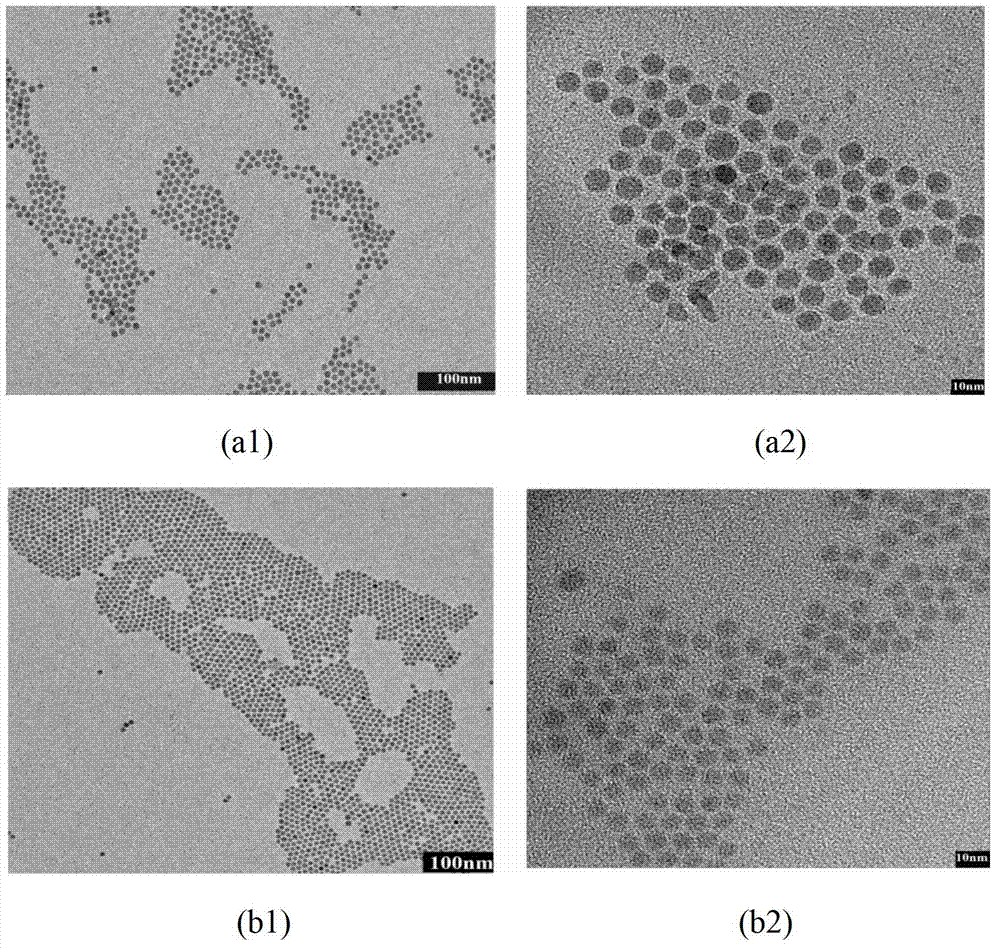

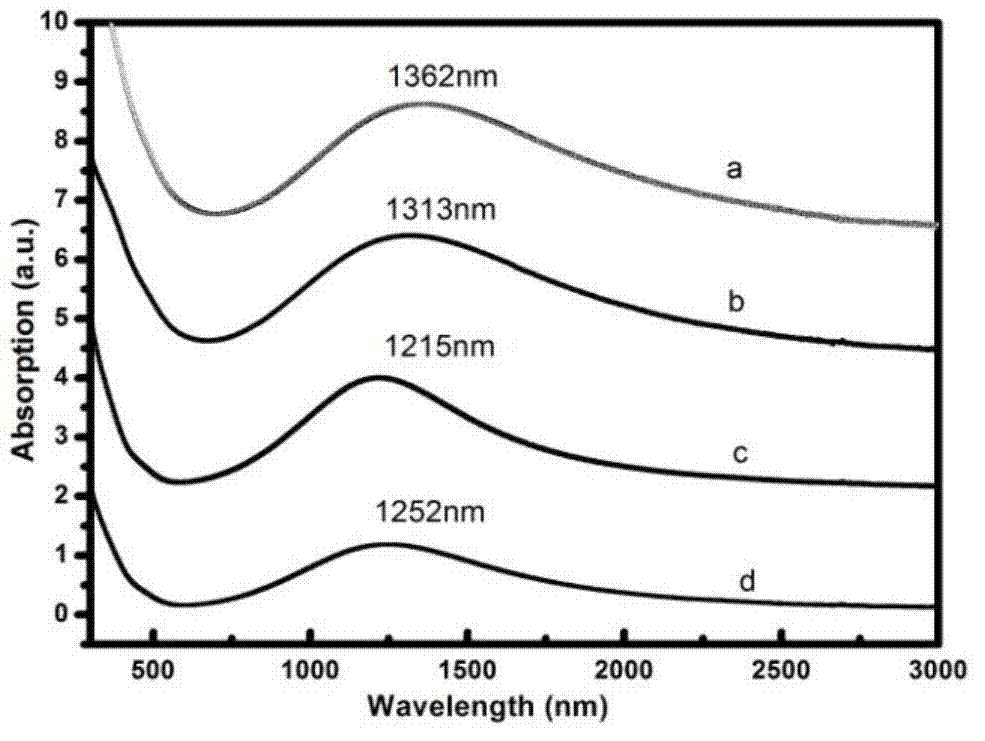

[0041] A p-type Cu of the present invention x S y A method for preparing semiconductor nanocrystals, the method steps are as follows:

[0042] Step 1: Prepare the copper source

[0043] Add 0.398g cuprous chloride, 2ml oleic acid, 1.5ml oleylamine and 1.5ml octadecene into a 25ml three-necked round bottom flask to obtain mixed solution 1. Vacuum the mixed solution 1 for 30 minutes, and then pass it into nitrogen protection , Under stirring conditions, heat the mixed solution 1 to 130°C and keep it for 30 minutes to form a uniform transparent dark green solution to obtain a copper source;

[0044] Step 2: Preparation of sulfur source

[0045] Add 0.064g of sulfur powder to a 50ml three-necked round-bottom flask, and then add 10ml of octadecene to obtain a turbid mixed solution 2. Vacuum the mixed solution 2 for 30 minutes, then pass it into nitrogen protection, and mix the mixed solution 2 under stirring conditions Heat to 180°C and keep for 10 minutes to form a uniform and transparen...

Embodiment 2

[0051] A p-type Cu of the present invention x S y A method for preparing semiconductor nanocrystals, the method steps are as follows:

[0052] Step 1: Prepare the copper source

[0053] Add 0.398g of cuprous chloride, 4ml of oleic acid, and 1.5ml of oleylamine into a 25ml three-necked round bottom flask to obtain mixed solution 1. Vacuum the mixed solution 1 for 30 minutes, and then pass it into nitrogen protection. The mixed solution 1 is heated to 90°C and kept for 30 minutes to form a uniform transparent dark green solution to obtain a copper source;

[0054] Step 2: Preparation of sulfur source

[0055] Add 0.032g of sulfur powder to a 50ml three-necked round-bottom flask, and then add 10ml of octadecene to obtain a turbid mixed solution 2. Vacuum the mixed solution 2 for 30 minutes, and then pass it into nitrogen protection, and mix the mixed solution 2 with stirring. Heat to 200°C and keep it for 10 minutes to form a uniform and transparent yellow solution to obtain a sulfur so...

Embodiment 3

[0061] A p-type Cu of the present invention x S y A method for preparing semiconductor nanocrystals, the method steps are as follows:

[0062] Step 1: Prepare the copper source

[0063] Add 13.500g of copper chloride, 50ml of oleic acid, and 40ml of oleylamine into a 250ml three-necked round bottom flask to obtain mixed solution 1. Vacuum the mixed solution 1 for 30 minutes, then pass it into nitrogen protection, and mix the solution under stirring 1 Heat to 150°C and keep for 30 minutes to form a uniform transparent dark green solution to obtain a copper source;

[0064] Step 2: Preparation of sulfur source

[0065] Add 1.6g of sulfur powder to a 250ml three-necked round bottom flask, and then add 100ml of octadecene to obtain a turbid mixed solution 2. The mixed solution 2 is evacuated for 30 minutes, and then nitrogen is protected. Under stirring, the mixed solution 2 Heat to 300°C and keep for 10 minutes to form a uniform and transparent yellow solution to obtain a sulfur source;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com