Negative temperature coefficient thermomagnetic composite sensitive resistance material and preparation method thereof

A negative temperature coefficient, composite sensitive technology, applied in the direction of resistors with negative temperature coefficient, resistors, inorganic material magnetism, etc., can solve problems such as single temperature sensitive characteristics, achieve high uniformity, single crystal phase, sintering temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

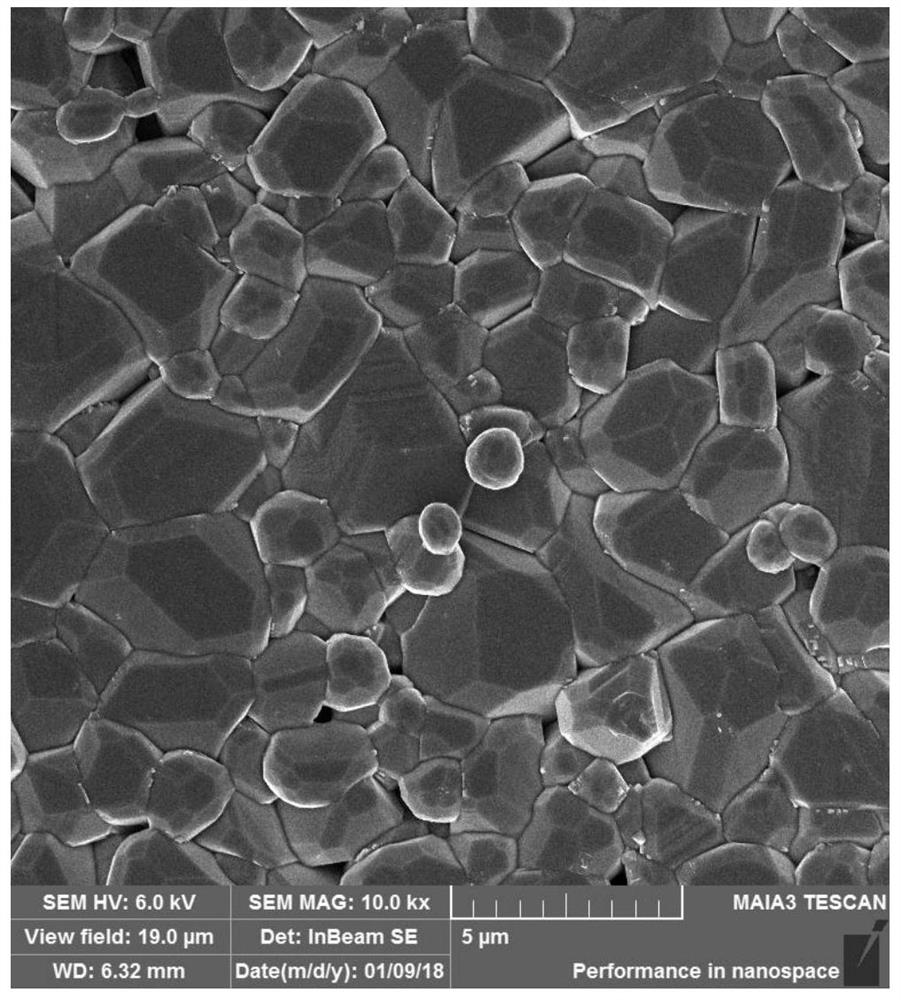

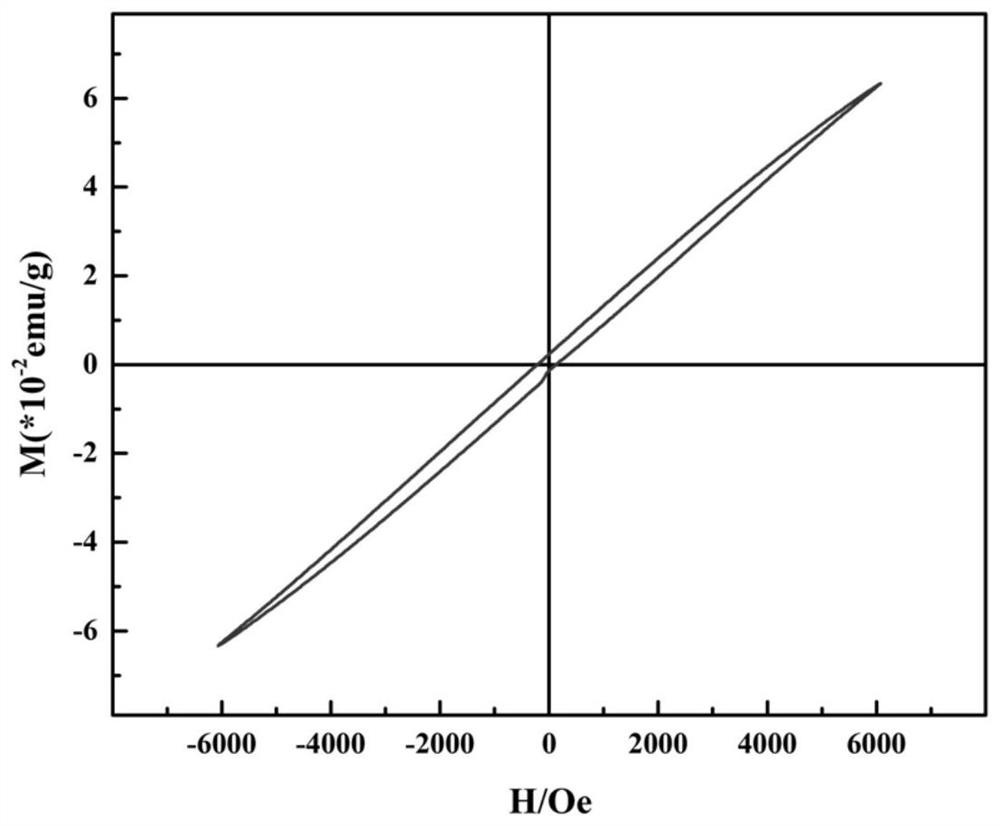

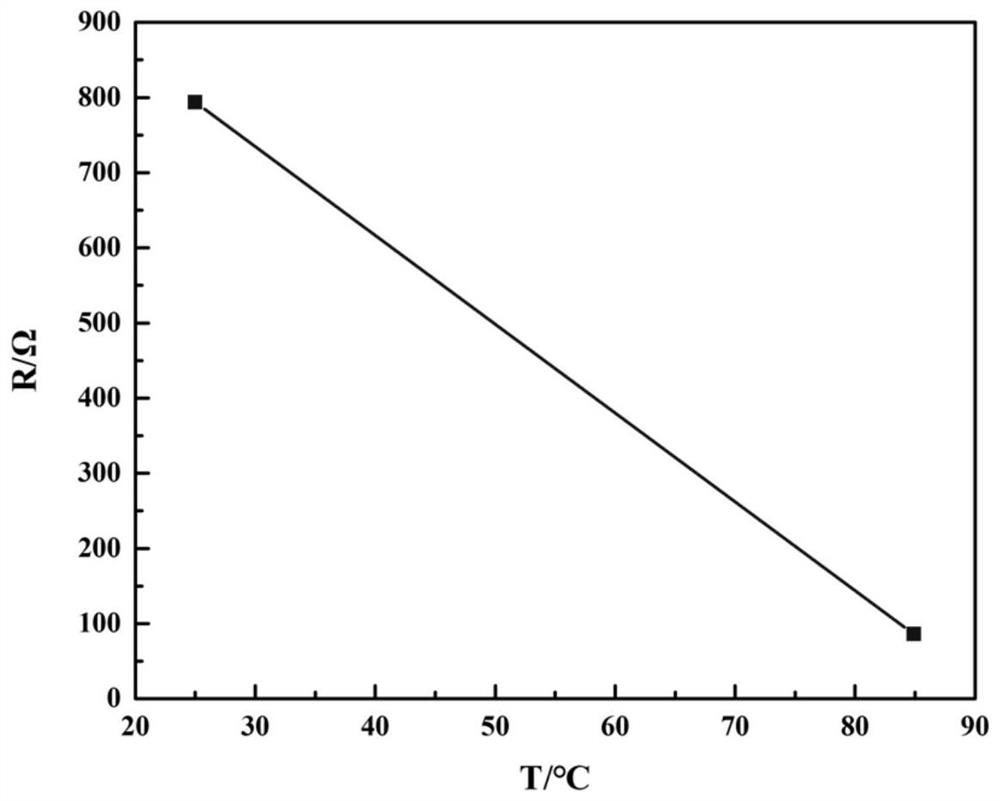

Image

Examples

Embodiment Construction

[0029] Implementation according to the following steps, each composition in Table 1 and Table 2 is an embodiment.

[0030] first step:

[0031] Accurately weigh each raw material according to the ratio in Table 1;

[0032] Step two:

[0033] Put the above mixture into a ball mill, use zirconia balls with a diameter of 2mm as the ball milling medium, use deionized water as the solvent, and use 50wt% polyacrylic acid aqueous solution as the dispersant, according to the weight ratio of mixture: ball: water: 1:3 : 1.5 was ground for 6 hours, discharging;

[0034] third step:

[0035] Pass the dry powder obtained in the second step through a 100-mesh sieve, place it in a corundum crucible, and synthesize Ni at 850°C for 1 hour. x co y mn 3-x-y o 4 Powder;

[0036] the fourth step:

[0037] The dried powder obtained in the third step is mixed with 10 wt% polyvinyl alcohol aqueous solution and then granulated, and the granulated size is controlled at 60 mesh;

[0038] the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com