A kind of preparation method of high-purity pseudo-boehmite

A pseudo-boehmite and high-purity technology, which is applied in the field of preparation of high-purity pseudo-boehmite, can solve the problems of uneven pore size, low crystal phase purity, and unstable products, and achieve stable products and no three wastes Emission, the effect of a single crystal phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

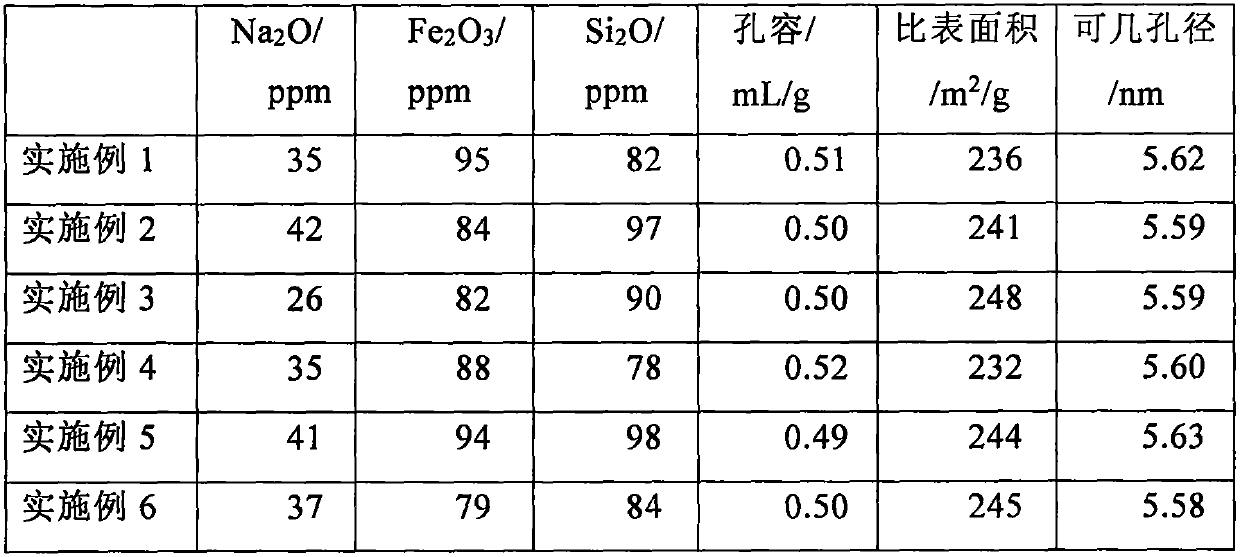

Examples

Embodiment 1

[0021] Add 10 grams of metallic aluminum, 0.02 grams of aluminum trichloride and 63 grams of n-hexanol into a four-neck flask, heat to 110°C to start the reaction, and slowly drop 126 grams of n-hexanol into the flask when a large number of bubbles are generated in the flask. After the reaction was completed, 99.7 g of trimethylbenzene was added to the flask, the temperature was raised to 110° C., and a mixture of tri-n-hexyloxyaluminum and trimethylbenzene was obtained by filtration. Add 30 mL of deionized water into the flask and raise the temperature to 85°C. A mixture of tri-n-hexaneoxyaluminum and trimethylbenzene at a temperature of 85°C was added dropwise to the flask while stirring was started, and the dropwise addition was completed in 30 minutes. The mixture of n-hexanol and trimethylbenzene produced by the hydrolysis of aluminum alkoxide was extracted from the flask. Add 225mL of deionized water to the flask and raise the temperature to 85°C, age for 12 hours and t...

Embodiment 2

[0023] The mixture of n-hexanol and trimethylbenzene extracted after the completion of hydrolysis in Example 1 continues to be used after dehydration treatment. Add a mixture of 10 grams of aluminum metal, 0.01 grams of aluminum trichloride, 0.01 grams of aluminum n-hexyl alcohol and 96.7 grams of n-hexanol and trimethylbenzene into a four-necked flask, and heat to 120°C to start the reaction. When a large number of bubbles are generated in the flask, the remaining n-hexanol and The trimethylbenzene mixture was slowly added dropwise into the flask, and filtered to obtain a mixture of tri-n-hexyloxyaluminum and trimethylbenzene. Add 30 mL of deionized water into the flask, raise the temperature to 85°C, and start stirring. Add the mixture of aluminum alkoxide and trimethylbenzene dropwise to the flask, and the dropwise addition is completed in 30 minutes. The mixture of n-hexanol and trimethylbenzene produced by the hydrolysis of aluminum alkoxide was extracted from the flask....

Embodiment 3

[0025] Add 10 grams of aluminum metal, 0.02 grams of aluminum trichloride and 45.7 grams of n-butanol into a four-necked flask, and heat to 100°C to start the reaction. When a large number of bubbles are generated in the flask, slowly drop 91.3 grams of n-butanol into the flask. After the reaction was completed, 90 grams of 200# solvent oil was added to the flask, the temperature was raised to 110° C., and the mixture of aluminum alkoxide and mesitylene was obtained by filtration. Add 30 mL of deionized water into the flask, raise the temperature to 85°C, and start stirring. Add the mixture of aluminum alkoxide and 200# solvent naphtha dropwise to the flask, and the dropwise addition is completed in 30 minutes. Extract the mixture of n-butanol and 200# solvent naphtha produced by the hydrolysis of aluminum alkoxide from the flask. Add 225mL of deionized water to the flask and raise the temperature to 85°C, age for 12 hours and then filter. The filter cake was dried at 120°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com