Process for making nano-sized and micro-sized precipitate particles

A nano-scale, sediment-based technology, applied in chemical methods for liquid-liquid reactions, nanotechnology, nanotechnology, etc., can solve problems such as environmental pollution sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

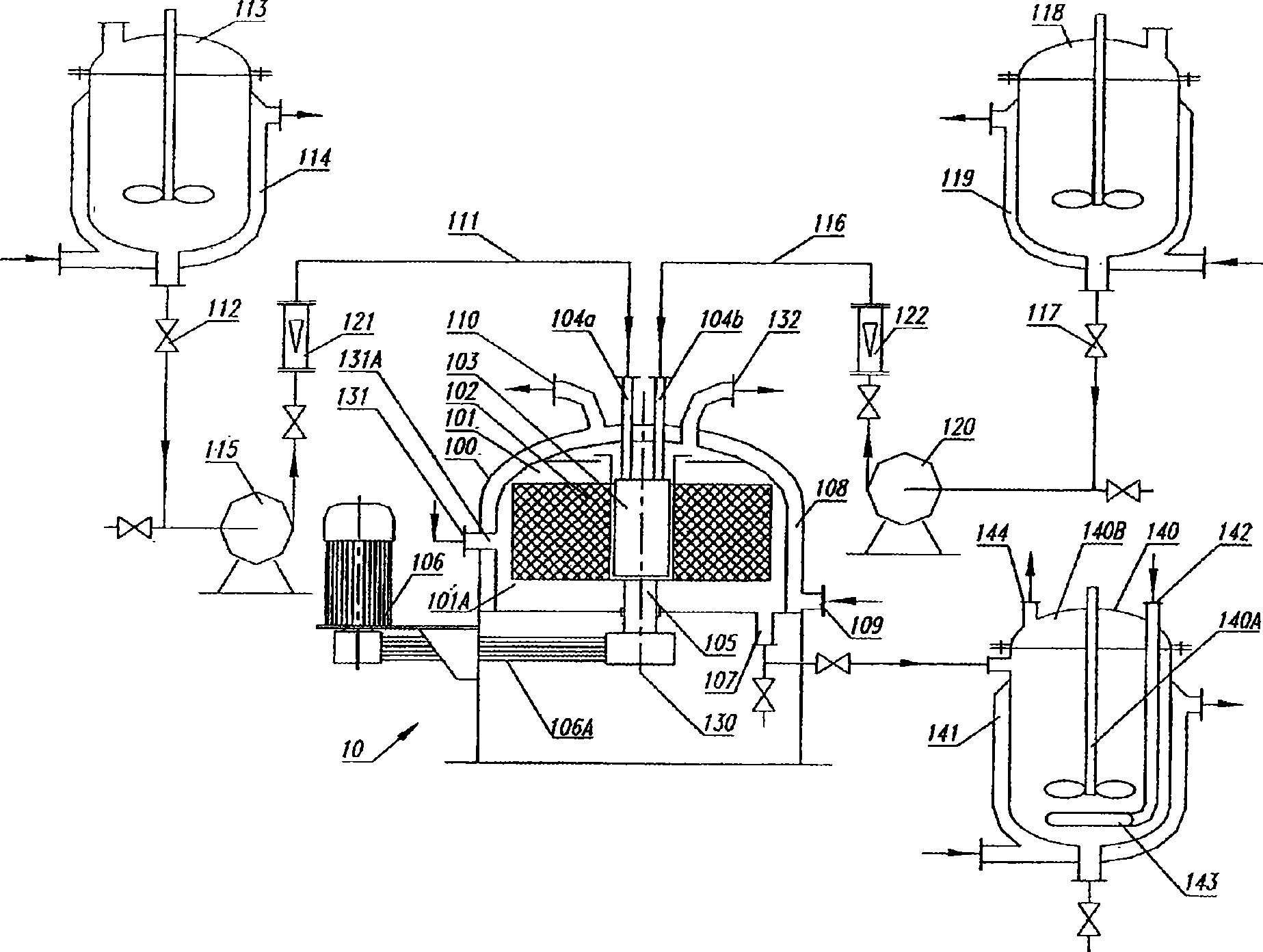

[0065] method

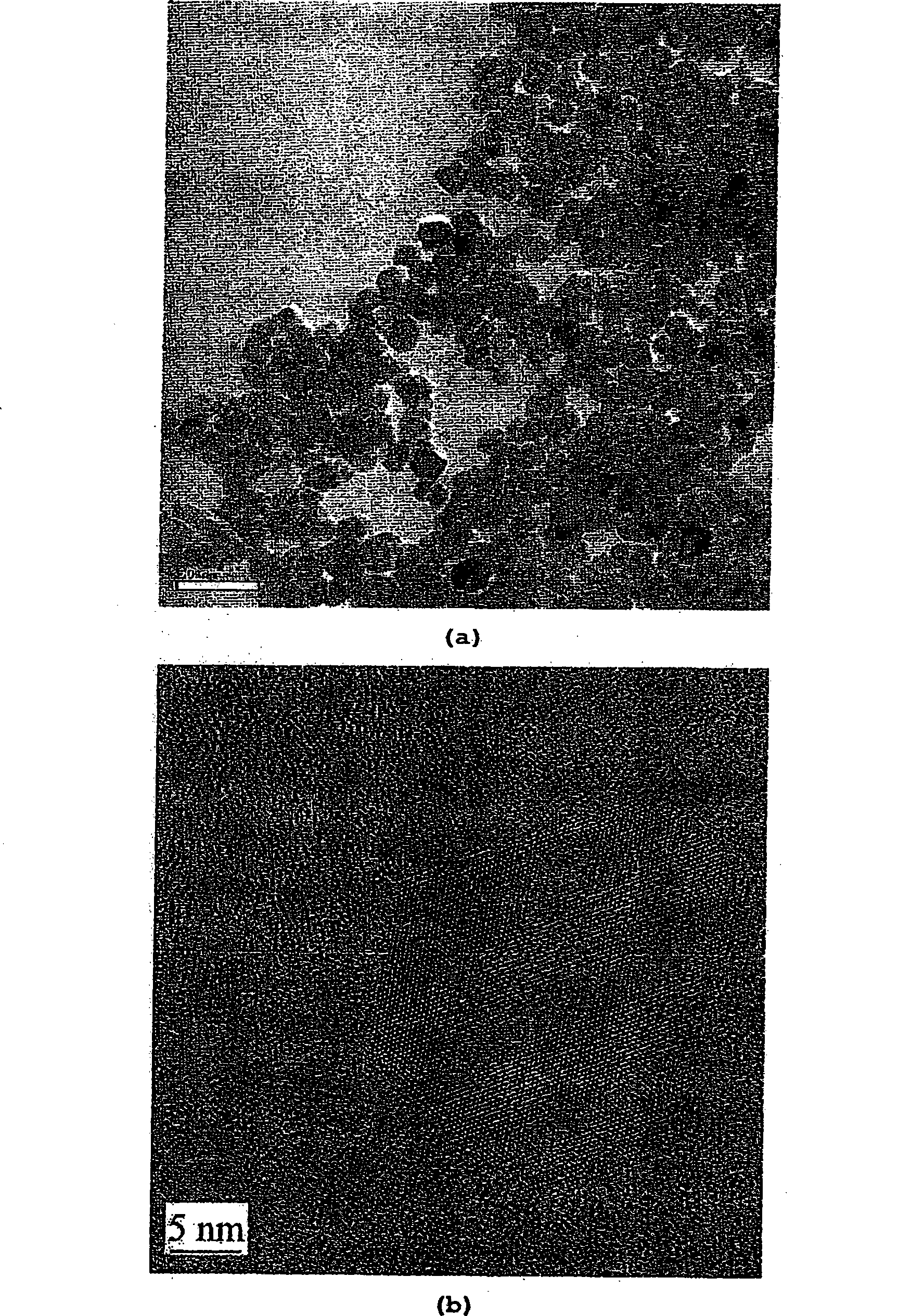

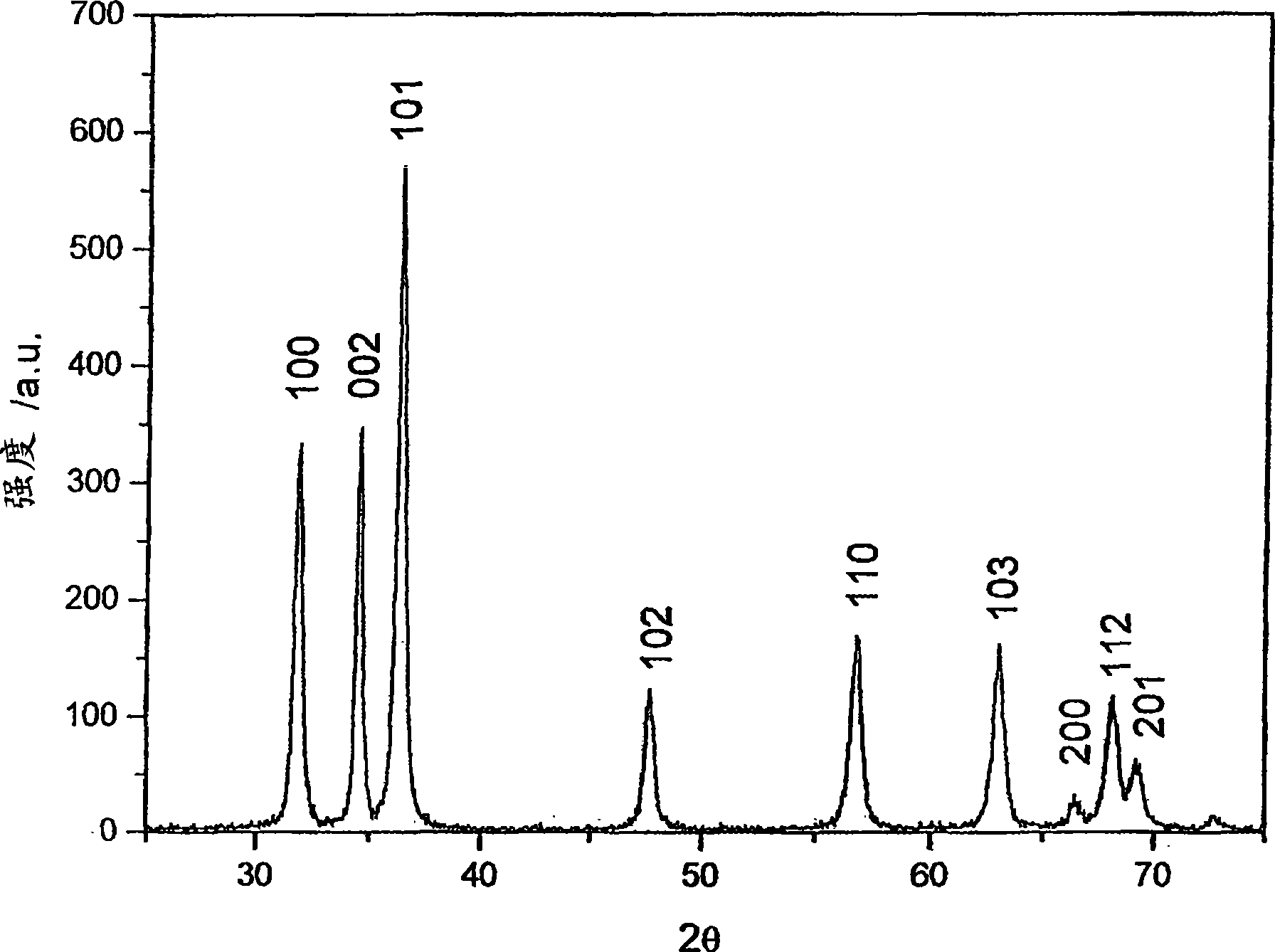

[0066] Exemplary, non-limiting embodiments of methods of preparing nanoscale metal chalcogenide and metal oxide particles are disclosed. The method includes the steps of mixing a metal salt solution with a precipitant solution under conditions to precipitate at least one of nanoscale metal chalcogenide and metal oxide particles.

[0067] The metal salt compounds used in the process may be completely or partially soluble in the chosen solvent. Preferably, the metal salt is a metal acetate, a metal halide salt, a metal nitrate, a metal phosphate, a metal sulfate, a hydrate thereof or a mixture thereof.

[0068] The metal of the metal salt solution may include a metal selected from alkali metals, alkaline earth metals, a metal selected from transition metals, and a metal selected from the main group of the periodic table. Exemplary metals for metal salts include Mg, Ca, Sr, Ba, Ag, Zn, Fe, Cu, Co, Al, Ce, Sn, Zr, Nb, Ti, and Cr.

[0069] The anions of the meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com