Method for preparing copper-indium-sulfur semi-conductor nano particles

A nanoparticle and semiconductor technology, applied in the field of preparation of copper indium sulfur semiconductor nanoparticles, can solve the problems of non-adjustable particle size and optical properties, unsuitable for large-scale preparation, complex synthesis steps, etc., and achieve easy large-scale The effect of production, easy control and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

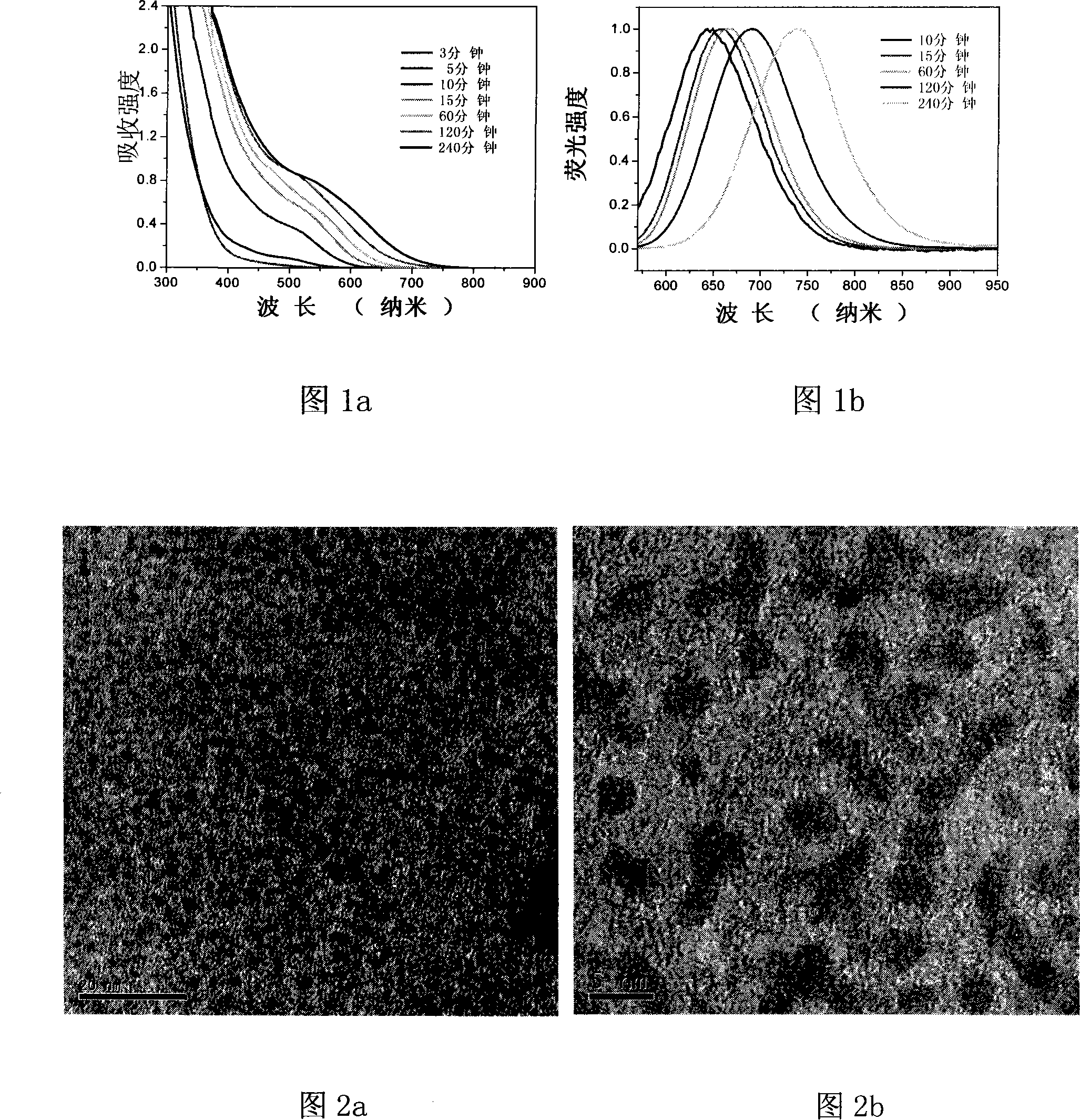

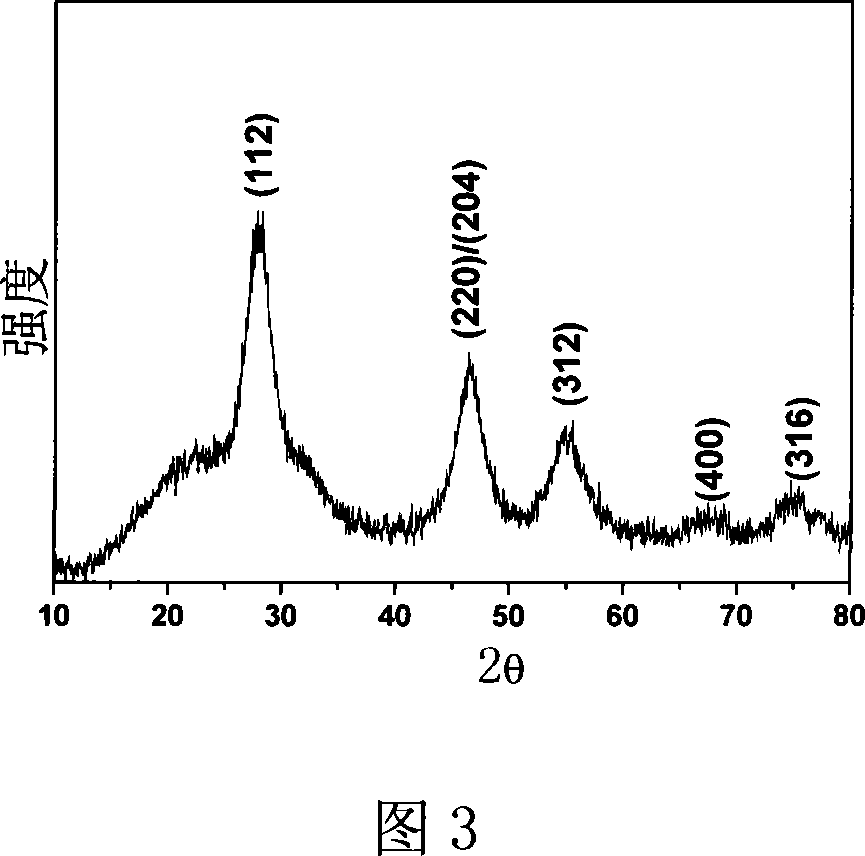

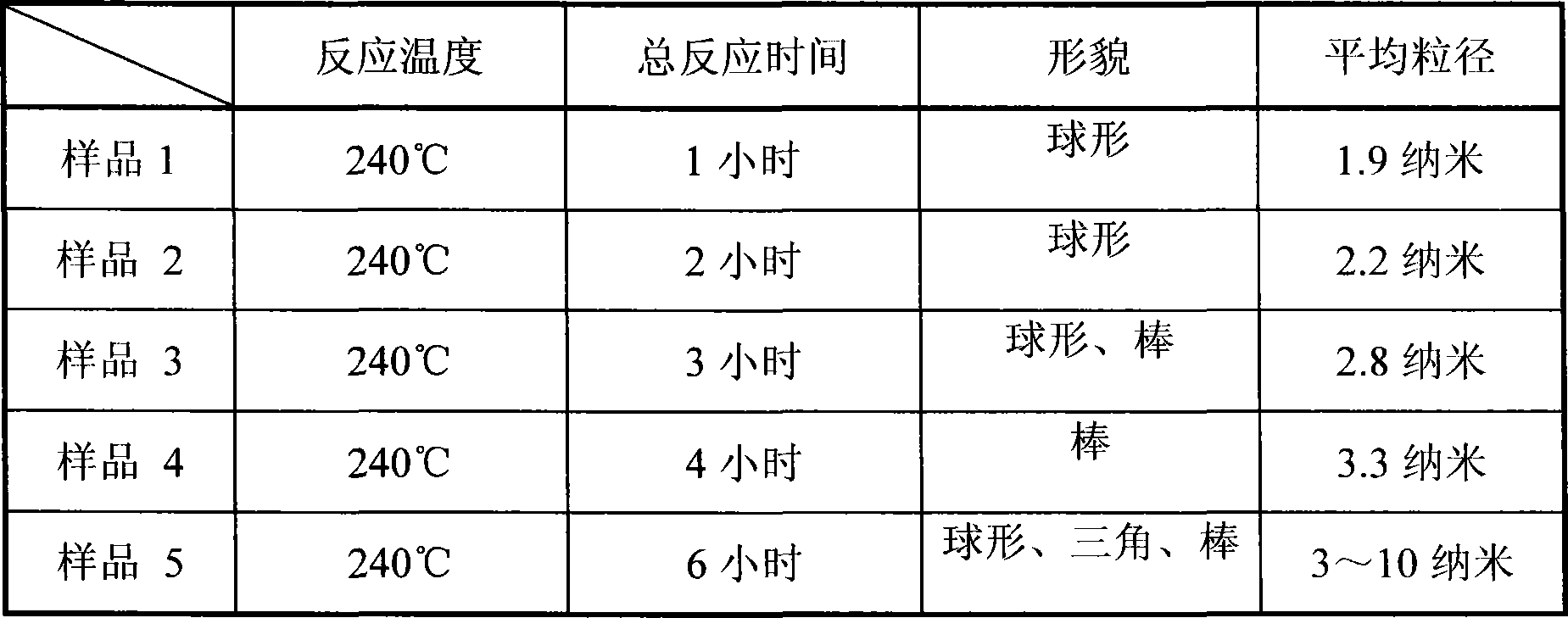

[0031] Example 1. Preparation of CuInS 2 semiconductor nanoparticles

[0032] Add the mixture of cuprous acetate, indium acetate and dodecyl mercaptan and 50ml of octadecene into a 100ml three-neck flask, wherein the molar ratio of cuprous acetate, indium acetate and dodecyl mercaptan is 1:1 : 10, through argon or nitrogen for 30 minutes to get rid of the air therein, heated and stirred at 240°C to obtain a clear light yellow solution, then continued to heat the mixed solution at 240°C, the color of the colloidal solution gradually changed from light yellow to Deep red, total heating reaction time 2 hours. Cool the colloidal solution obtained from the above reaction to room temperature, add 100ml of acetone, centrifugally settle, remove the upper solution, and obtain copper indium sulfur semiconductor nanoparticles. Copper indium sulfur semiconductor nanoparticles with different shapes and sizes can be obtained by changing the reaction time (see Table 1 for specific conditio...

Embodiment 2

[0035] Example 2. Preparation of CuInS 2 semiconductor nanoparticles

[0036]Add the mixture of copper acetate, indium acetate and hexadecyl mercaptan and 25ml of octadecene into a 100ml three-neck flask, wherein the molar ratio of copper acetate, indium acetate and hexadecyl mercaptan is 1:1:10 , pass argon or nitrogen for 30 minutes to remove the air, heat and stir at 270°C to obtain a clear light yellow solution, and then continue to heat the mixed solution at a constant temperature of 270°C. The total heating reaction time is 20 minutes; a colloidal solution will be obtained The colloid solution was cooled to room temperature, 100ml of acetone was added, and the copper indium sulfur semiconductor nanoparticles with an average particle size of 3.3nm were obtained by centrifugal sedimentation.

Embodiment 3

[0037] Example 3. Preparation of CuInS 2 semiconductor nanoparticles

[0038] Add the mixture of copper acetate, indium acetate and hexadecyl mercaptan and 50ml of octadecene into a 250ml three-neck flask, wherein the molar ratio of copper acetate, indium acetate and hexadecyl mercaptan is 1:1:100 , pass argon or nitrogen for 30 minutes to remove the air, heat and stir at 240°C to obtain a clear light yellow solution, and then continue to heat the mixed solution at a constant temperature of 240°C to obtain a black sol. The total heating reaction time is 3 hours; The obtained colloidal solution was cooled to room temperature, 100 ml of acetone was added, and copper indium sulfur semiconductor nanoparticles with an average particle diameter of 3.5 nm were obtained by centrifugal sedimentation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com