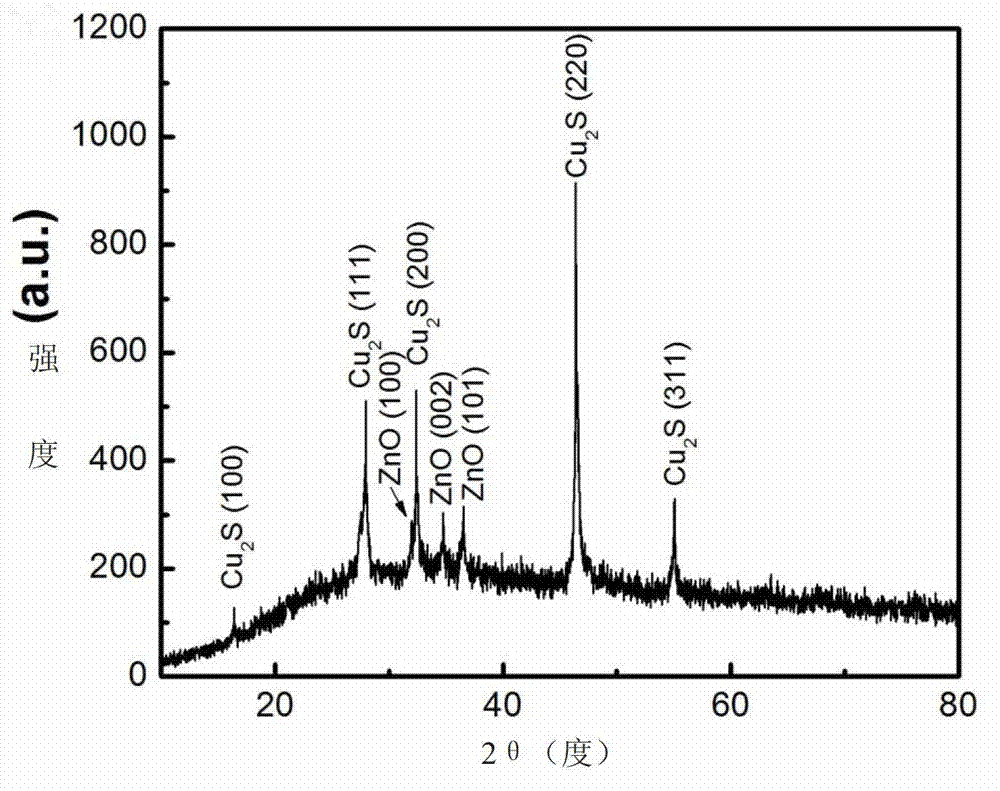

Three-dimensional Cu2S@ZnO nanometer heterostructure semiconductor material and preparation method thereof

A nano-heterostructure, semiconductor technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of inapplicability to large-scale industrial production, high production costs, harsh reaction conditions, etc., and meet the requirements of reducing equipment , low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

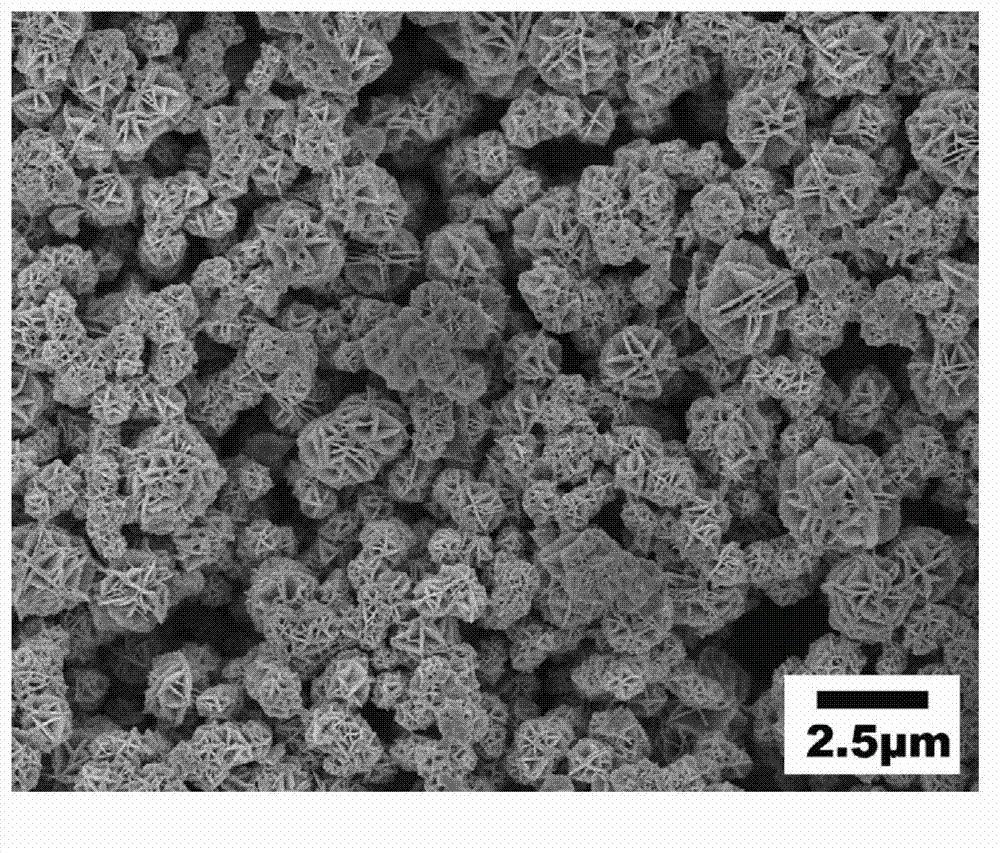

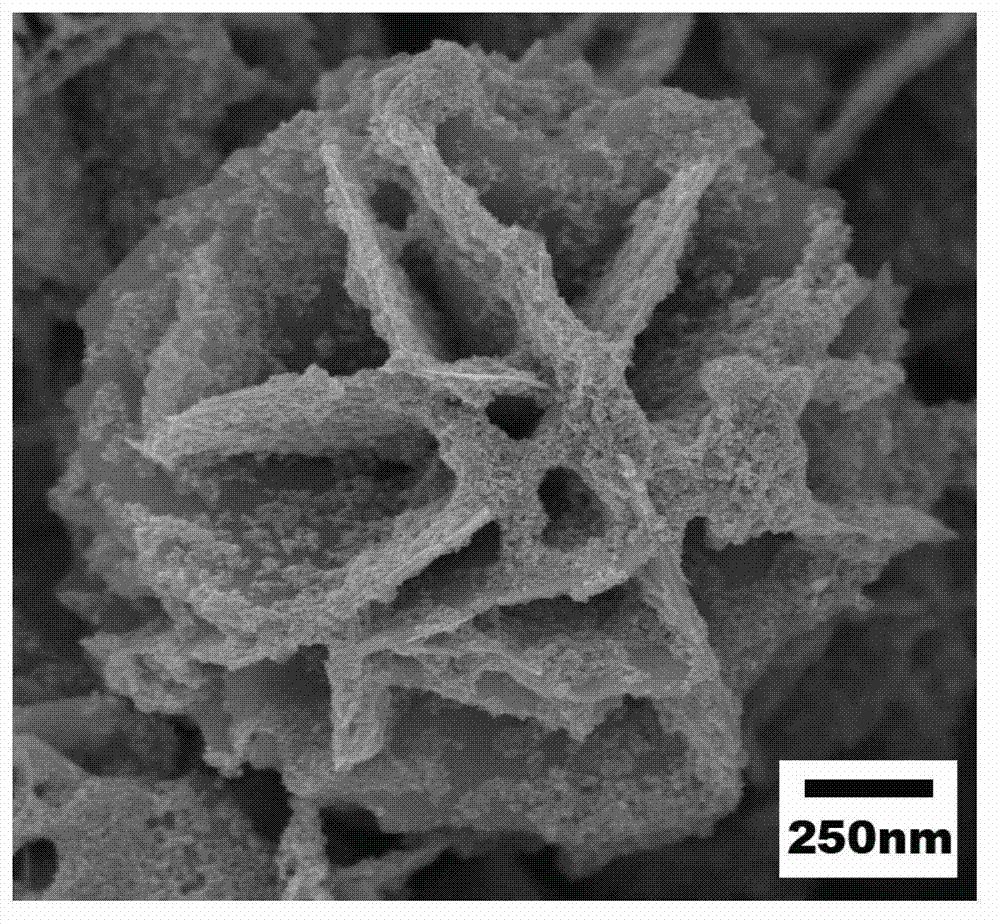

[0029] In this example, the three-dimensional Cu 2 The specific preparation steps of SZnO nano-heterostructure semiconductor material are as follows:

[0030] a. Mix 0.5g of cuprous chloride, 0.4g of thiourea and 0.25g of PVP, dissolve in 40mL of 95% ethanol and stir thoroughly for 30 minutes.

[0031] b. Then transfer the mixed solution into a 50mL reaction kettle, place the reaction kettle in a vacuum oven and heat it at 180°C for 6h, when the reaction is finished and cool to room temperature, collect the black reaction product and wash it repeatedly with absolute ethanol and deionized water several times.

[0032] c. Dry the pure sample in a vacuum oven at 60°C for use. Among them, the sample here refers to Cu 2 S sample, that is, the prepared flower-like Cu 2 S nanostructured substrate materials.

[0033] d. Add 10mL of urea solution (2M) dropwise to 10mL of ZnCl (0.5M), then dissolve it in 80mL of deionized water, stir the mixed solution magnetically for 30min and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com