Fast semiconductor heat-treating facility with vertical heat treating chamber

A rapid heat treatment, semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of large footprint and difficult to control the heating and cooling process of semiconductor wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

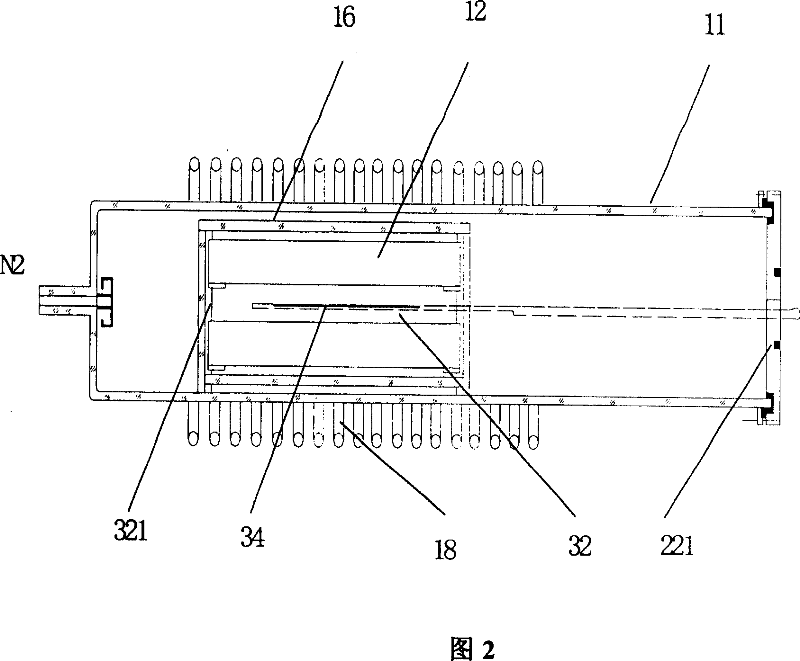

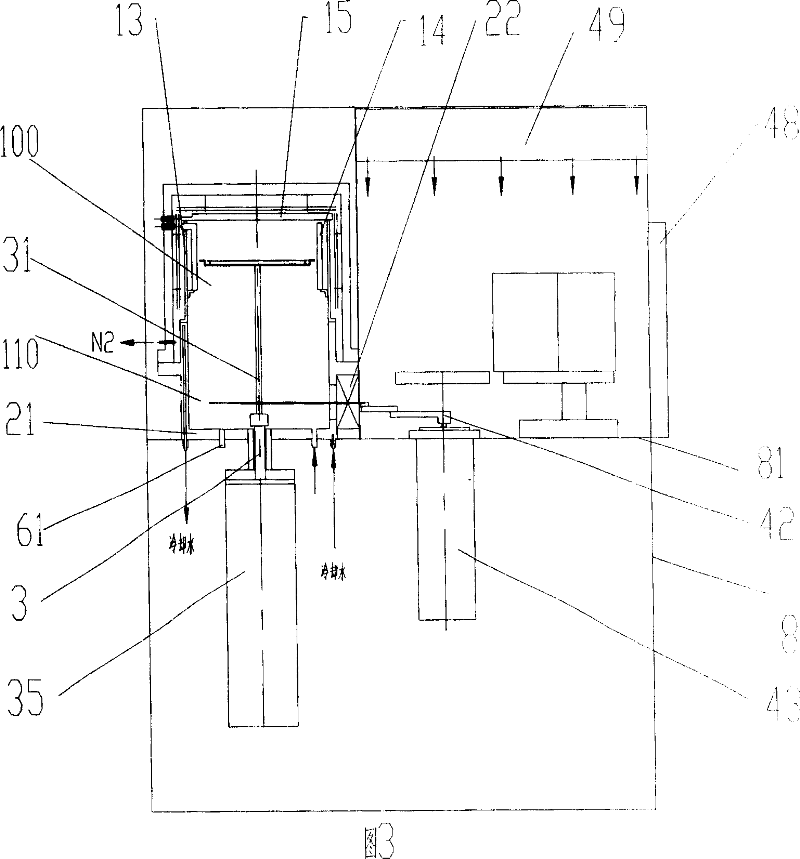

[0075] Fig. 3 is a schematic diagram of a semiconductor rapid heat treatment equipment with a vertical heat treatment chamber according to the present invention. Fig. 4 is a schematic structural view of the vertical cylindrical heat treatment chamber in Fig. 3 . Fig. 5 is a schematic diagram of the cassette-to-cassette pick-and-place robot subsystem in Fig. 3 . Fig. 6 is a schematic diagram of a direct current flat graphite heater. Fig. 7 is a schematic diagram of a direct current cylindrical graphite heater.

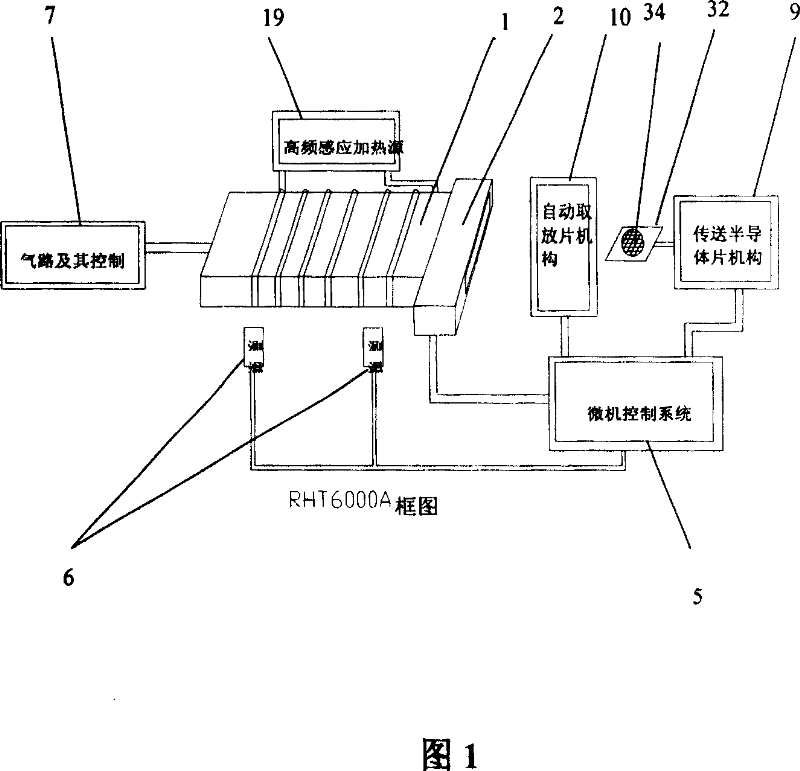

[0076] The semiconductor rapid heat treatment equipment with vertical heat treatment chamber mainly includes: vertically arranged heat treatment chamber 1, wafer loading chamber 2, semiconductor wafer lifting mechanism 3; also includes a cassette-to-cassette three-folding arm robot subsystem 4 , Microcomputer control subsystem 5, temperature measurement and control subsystem 6, gas circuit device 7, heating power supply 19.

[0077] The heat treatment chamber mainly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com