Method for preparing boron nitride fiber cloth by using precursor conversion

A boron nitride fiber and precursor technology, which is applied in the field of ceramic materials, can solve the problems of insufficient strength of boron nitride fiber and the inability to directly weave cloth, etc., and achieve the effects of easy large-scale production, strong adsorption capacity, and excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

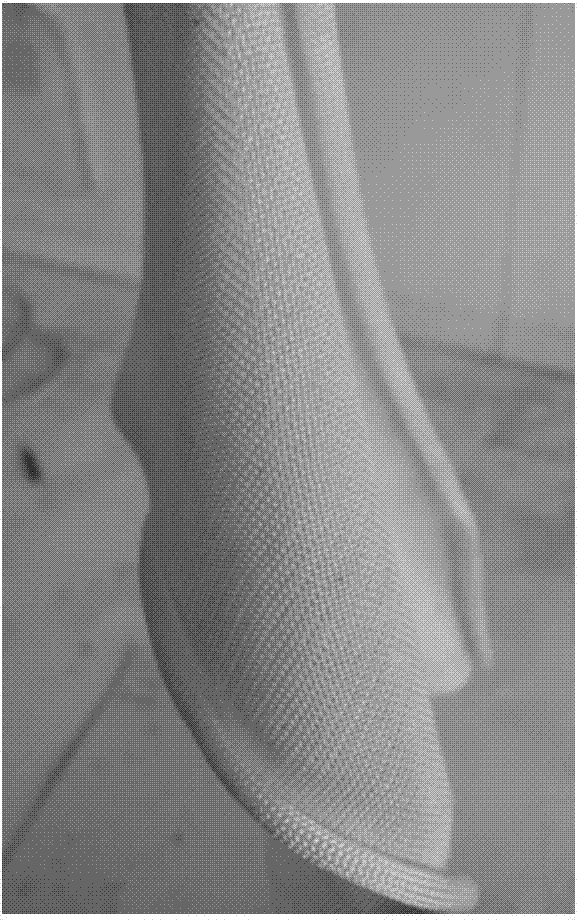

Image

Examples

Embodiment 1

[0027] Melt 5kg of boric acid in a chemical crucible at 800°C for 5 hours until the melt is transparent, clear and free of bubbles. A 200-hole platinum wire drawing bushing was used for wire drawing. The bushing temperature was 600°C and the speed of the drawing head was 3500 rpm to obtain boron oxide fiber yarns with 200 fibers and a diameter of 8.2 μm. The obtained 2 bundles of 200 boron oxide fiber yarns were plied by plying and twisting equipment to obtain 400 boron oxide fiber rovings.

[0028] The boron oxide fiber roving is woven with a weaving equipment, and the woven sample is kept at 600°C for 2 hours in an ammonia atmosphere, and the ammonia flow rate is 1m 3 / h, and the heating rate is 30°C / min, to obtain a low-temperature nitrided boron nitride fiber cloth. The above fiber cloth was heat-treated at a high temperature of 1400°C for 60 minutes in a vacuum carbon tube furnace with a heating rate of 8°C / h to obtain a boron nitride fiber cloth.

[0029] The prepared ...

Embodiment 2

[0031] Melt 5kg of boric acid in a chemical crucible at 800°C for 5 hours until the melt is transparent, clear and free of bubbles. A 200-hole platinum wire-drawing bushing was used for wire drawing. The bushing temperature was 700°C and the speed of the drawing head was 4000 rpm to obtain boron oxide fiber yarns with 200 fibers and a diameter of 8.3 μm. The obtained 5 bundles of 200 boron oxide fiber yarns were plied by plying and twisting equipment to obtain 1000 boron oxide fiber rovings.

[0032] The boron oxide fiber roving is woven by weaving equipment, and the woven sample is kept at 750°C for 4 hours in an ammonia atmosphere, and the ammonia flow rate is 3m 3 / h, and the heating rate is 40°C / min, to obtain a low-temperature nitrided boron nitride fiber cloth. The above fiber cloth was heat-treated at a high temperature of 1450° C. for 80 minutes in a vacuum carbon tube furnace with a heating rate of 10° C. / h to obtain a boron nitride fiber cloth.

[0033] The prepare...

Embodiment 3

[0035] Melt 5kg of boric acid in a chemical crucible at 900°C for 10 hours until the melt is transparent, clear and free of bubbles. A 200-hole platinum wire drawing bushing was used for wire drawing. The bushing temperature was 700°C and the speed of the drawing head was 3800 rpm to obtain 200 boron oxide fiber yarns with a diameter of 7 μm. The obtained 5 bundles of 200 boron oxide fiber yarns were plied by plying and twisting equipment to obtain 1000 boron oxide fiber rovings.

[0036] The boron oxide fiber roving is woven by weaving equipment, and the woven sample is kept at 700°C for 3 hours in an ammonia atmosphere, and the ammonia flow rate is 4m 3 / h, and the heating rate is 45°C / min, to obtain a low-temperature nitrided boron nitride fiber cloth. The above fiber cloth was heat-treated at 1480°C in a nitrogen atmosphere in a vacuum carbon tube furnace for 60 minutes at a high temperature with a heating rate of 10°C / h to obtain a boron nitride fiber cloth.

[0037] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com