Device and method for controlling heating and cooling temperature of heat conduction oil reactor

A technology for cooling temperature and heat transfer oil, applied in chemical instruments and methods, chemical/physical/physical chemical process, chemical/physical process, etc., can solve the problems of equipment leakage, high temperature of cold oil tank and easy oxidation, large temperature difference of equipment, etc. Achieve the effect of reducing power and energy consumption, shortening production time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

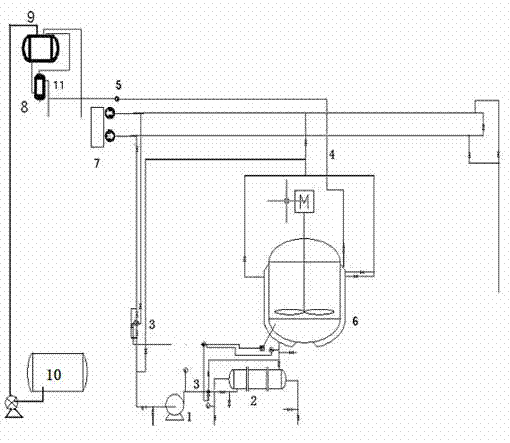

[0016] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a heat transfer oil reactor 6, which is connected to a heat transfer oil cooler 2, both of which are respectively connected to a heat transfer oil internal circulation pump 1, and the heat transfer oil cooler 2 can be air-cooled or water-cooled. The heat transfer oil internal circulation pump 1 is connected to the boiler 7 through a three-way regulating valve 3 (boiler 7 is where the heat transfer oil comes and goes), and is connected to the heat transfer oil cooler 2 and the heat transfer oil reactor 6 through another three-way regulating valve 3 , the heat transfer oil reactor 6 is connected to the expansion tank A5 through the exhaust and oil supply pipeline 4, and the system composed of the heat transfer oil internal circulation pump 1, the heat transfer oil cooler 2, and the heat transfer oil reactor 6 is added and connected to the expansion tank A5 The exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com