A Treatment Method for Improving the Strength, Toughness and Dimensional Stability of Whisker Reinforced Aluminum Matrix Composite Forging Blanks

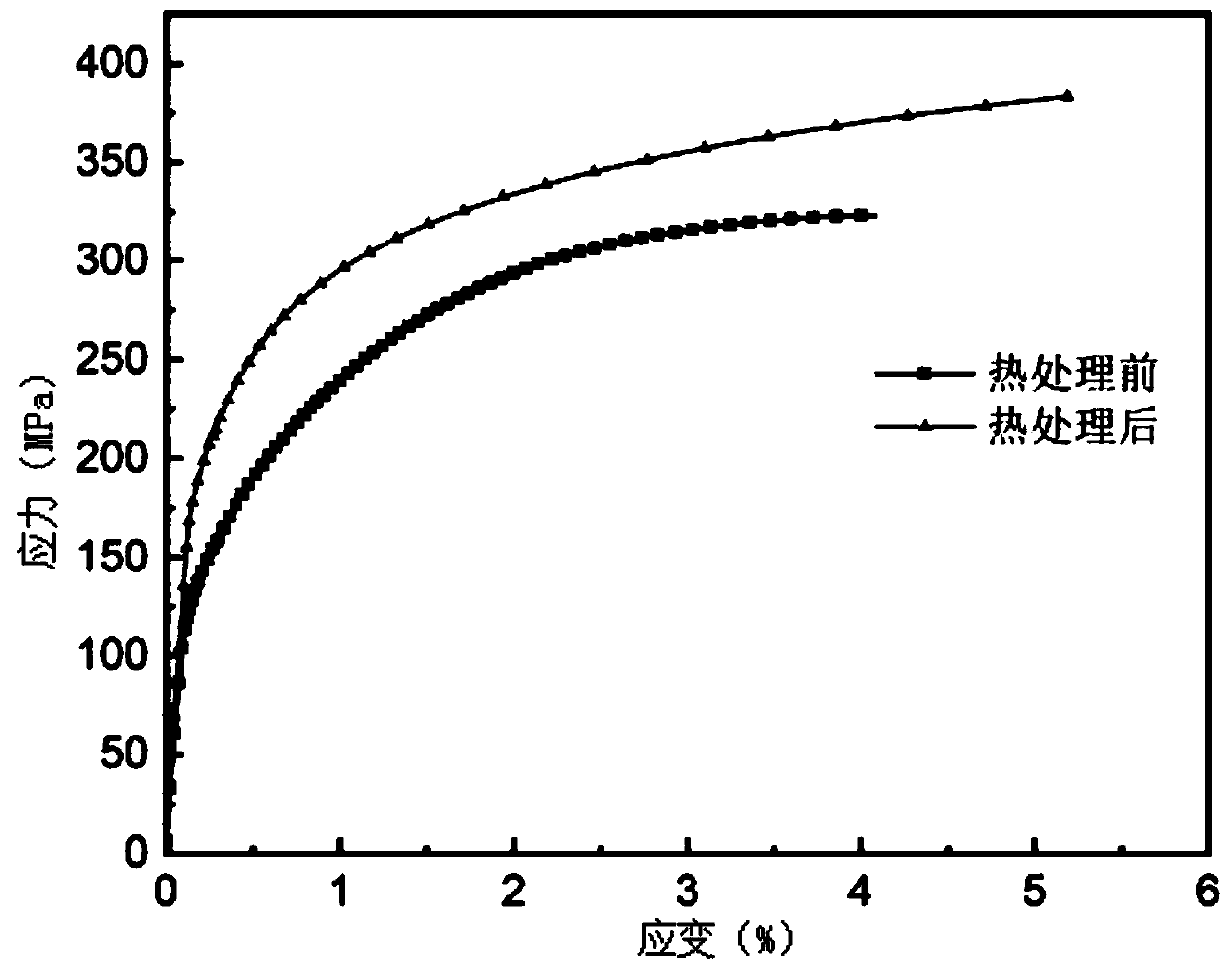

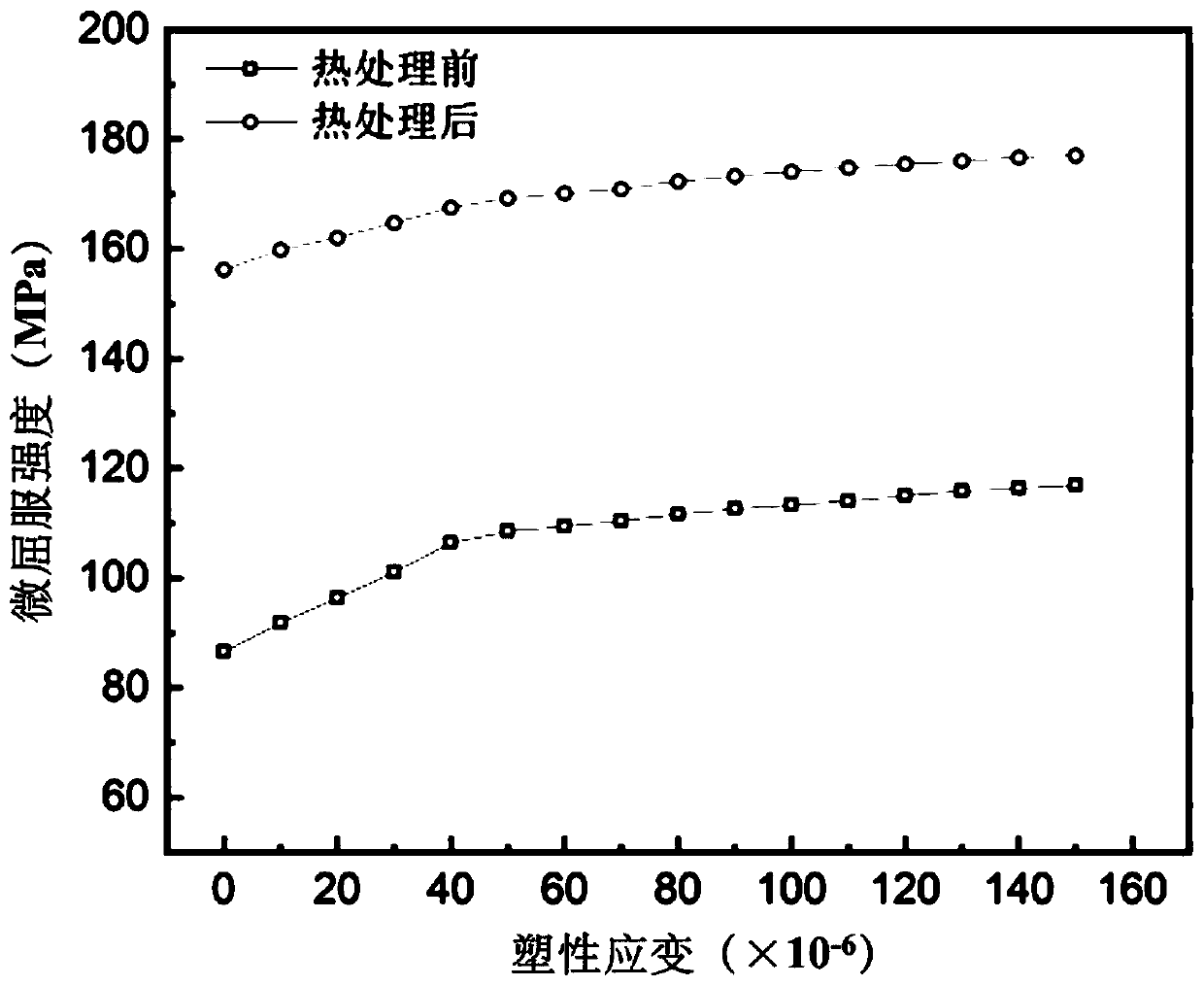

A technology of dimensional stability and processing method, which is applied in the field of whisker-reinforced aluminum matrix composite material processing to achieve the effect of improving strength, toughness and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

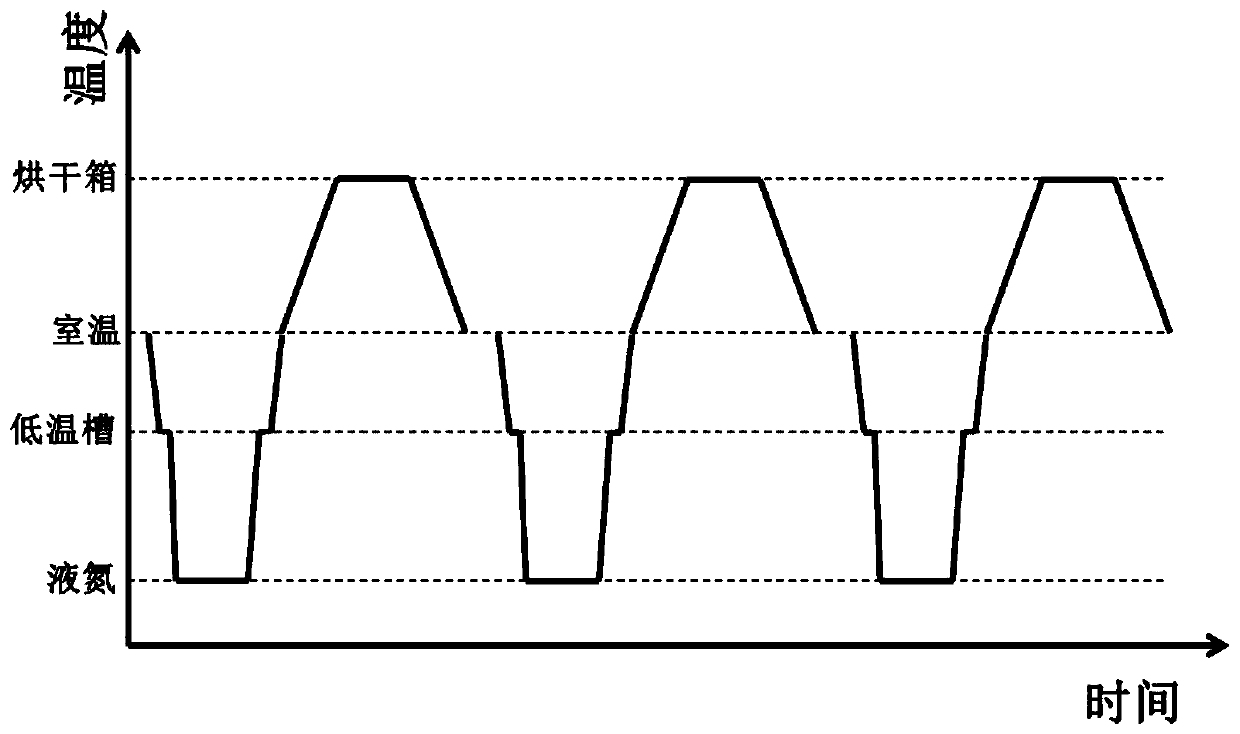

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, the SiCw / 6061Al composite material that silicon carbide whisker (SiCw) volume fraction of this embodiment is 20vol.%, the treatment method that improves whisker-reinforced aluminum-based composite forging billet toughness and dimensional stability is as follows Steps completed:

[0030] Step 1. Preheat the whisker-reinforced aluminum matrix composite ingot for 300 minutes at 520°C±3°C, and preheat the upper and lower anvils of the press at the same time. The preheating temperature is 520°C±3°C. for 2h;

[0031] The ingot preheating heating time is according to t=d×k=(40mm)×(7.5min / mm).

[0032] Step 2. Place the ingot on the press, upsetting axially first, then upsetting radially, rotating 90° along the circumferential direction, and then upsetting radially. The axial strain is 0.4, and the axial strain rate is 0.04 / s; the radial compression strain is 0.2, and the radial strain rate is 0.02 / s;

[0033] Step 3, repeat the operation of step 2 4 times to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com