Copper sulfide superstructure and its application in improving near infrared thermal conversion efficiency

A superstructure, copper sulfide technology, applied in the direction of copper sulfide, phototherapy, etc., to achieve the effect of cost price, good chemical stability, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Add 2g PVP to 10mL deionized water, then add 1mmol CuCl under stirring 2 2H 2 O, a mixed solution was obtained;

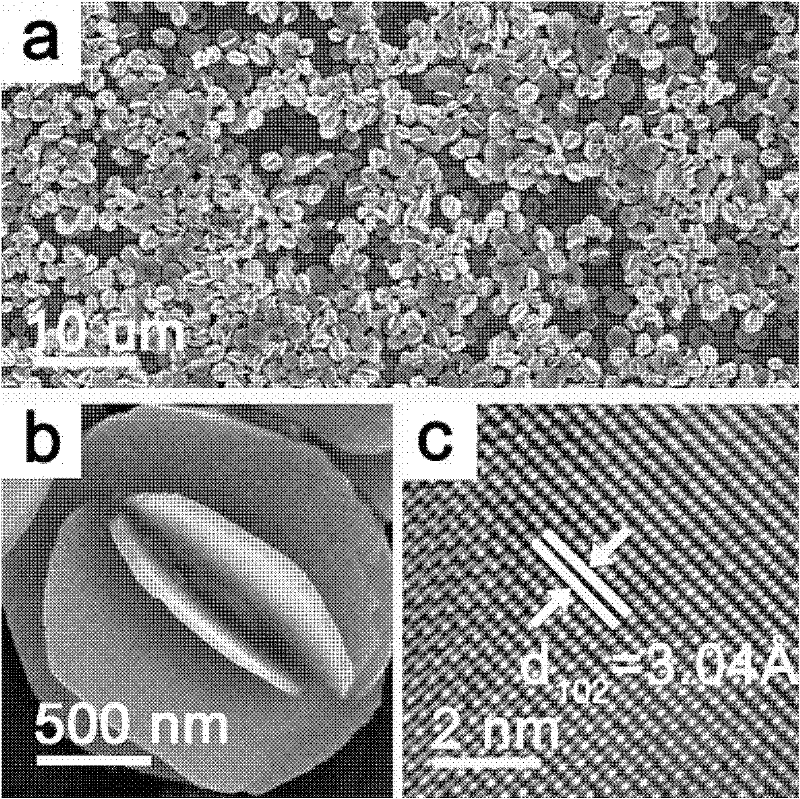

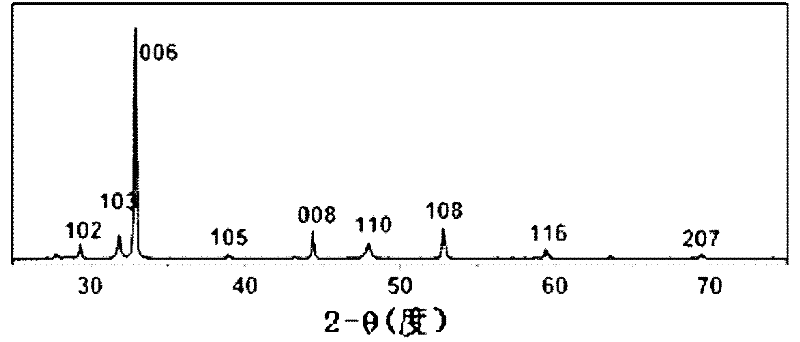

[0027] (2) Weigh 3mmol of Na 2 S, dissolved in 10mL deionized water, then add the above mixed solution under stirring, continue to stir for half an hour, then transfer to the hydrothermal reaction kettle, the reaction time is 24 hours, the temperature is 240 ° C, after the reaction is complete, centrifuge , to obtain the CuS superstructure; the superstructure is composed of CuS flake nano-units arranged in an orderly manner, with a particle size of 2nm.

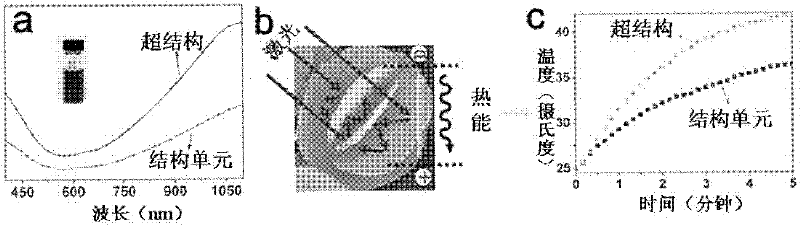

[0028] (3) The copper sulfide superstructure was redispersed in water at a concentration of 0.25 mg / mL. Using a 1W 980nm laser, the photothermal conversion performance was tested, and the temperature was increased by 17.5 degrees Celsius.

Embodiment 2

[0030] (1) Add 2g PVP to 100mL deionized water, then add 1mmol CuCl under stirring 2 2H 2 O, a mixed solution was obtained;

[0031] (2) Weigh 1mmol of Na 2 S, dissolved in 100mL deionized water, then added the above mixed solution under stirring, and then transferred to the hydrothermal reaction kettle, the reaction time was 32 hours, the temperature was 180 ° C, after the reaction was complete, centrifuged to obtain the CuS superstructure , the superstructure is composed of ordered CuS flake nano-units with a particle size of 100nm.

[0032] (3) The copper sulfide superstructure was redispersed in phosphate buffered saline PBS at a concentration of 0.25mg / mL, and its photothermal conversion performance was tested using a 1W980nm laser, and the temperature was increased by 16 degrees Celsius.

Embodiment 3

[0034] (1) Add 4g PVP to 10mL deionized water, then add 0.5mmol CuCl under stirring 2 2H 2 O, a mixed solution was obtained;

[0035] (2) Weigh 2.5mmol of Na 2 S, dissolved in 10mL deionized water, then add the above mixed solution under stirring, continue to stir for half an hour, then transfer to a hydrothermal reaction kettle, the reaction time is 32 hours, the temperature is 180 ° C, after the reaction is complete, centrifuge , to obtain the CuS superstructure, which is composed of CuS flake nano-units arranged in an orderly manner, with a particle size of 800nm.

[0036] (3) The copper sulfide superstructure was redispersed in PBS at a concentration of 0.25 mg / mL, and its photothermal conversion performance was tested using a 1W 808nm laser, and the temperature was increased by 14 degrees Celsius.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com