Nanofiber vascular prostheses and preparation method

A technology of nanofibers and artificial blood vessels, applied in fiber processing, spinning solution preparation, medical science, etc., can solve the problems of unfavorable gelatin membranes, achieve the effects of preventing blood penetration, improving physical and mechanical properties, and promoting endothelialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A nanofiber artificial blood vessel is made by the following method:

[0039] (1) dissolving gelatin in glacial acetic acid to prepare 20 mL of gelatin solution with a mass fraction of 15%;

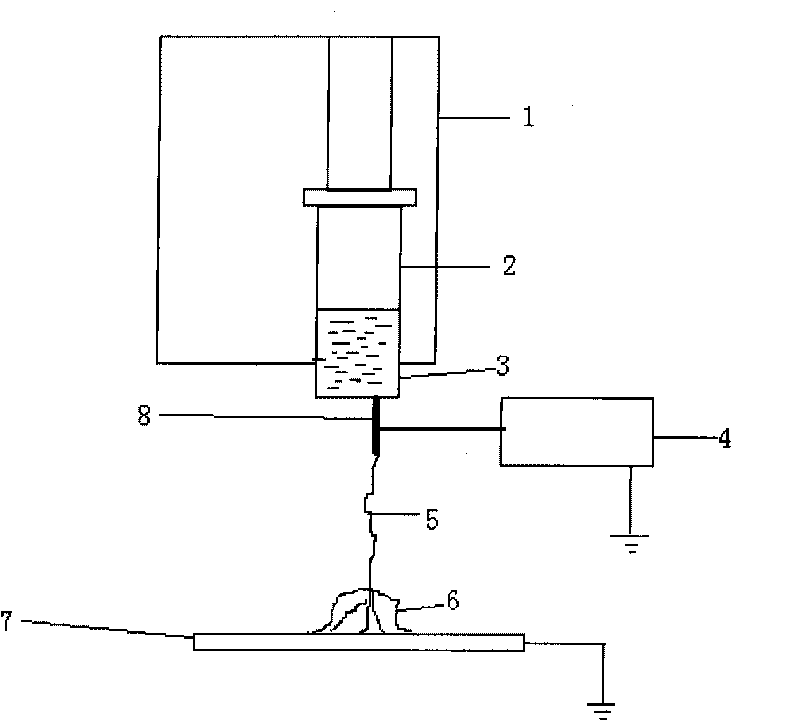

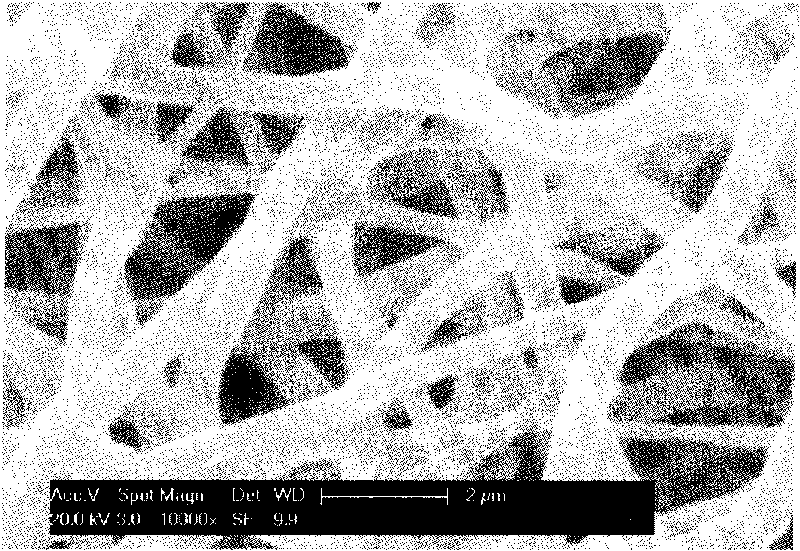

[0040] (2) Add 1 mL of an aqueous solution of glutaraldehyde with a mass percentage concentration of 50% and mix well to make it moderately pre-crosslinked, and add 5 mL of an aqueous solution of heparin sodium with a mass concentration of 0.9% to form a gelatin-heparin sodium spinning solution. Silk stock solution; the spinning stock solution is loaded into the electrospinning equipment, and the electrospinning process is adopted (process parameters: voltage 15kV, receiving distance 15cm, solution flow rate 0.6mL / h, collection roller speed 100r / min, needle No. 5 needle), the fibers ejected and formed from the spinning nozzle in the electrospinning equipment are collected on the collection roller, and the electrospinning is continued for 5 hours to form a nanofiber non-woven film t...

Embodiment 2

[0044] A nanofiber artificial blood vessel is made by the following method:

[0045] (1) dissolving gelatin in glacial acetic acid to prepare 20 mL of gelatin solution with a mass fraction of 15%;

[0046] (2) Add 1 mL of an aqueous solution of genipin with a concentration of 10% by mass and mix well to make it moderately pre-crosslinked, and add 5 mL of an aqueous solution of sodium heparin with a concentration of 1.5% to form gelatin-sodium heparin spinning Silk stock solution; the spinning stock solution is loaded into the electrospinning equipment, and the electrospinning process is adopted (process parameters: voltage 15kV, receiving distance 15cm, solution flow rate 0.5mL / h, collection roller speed 100r / min, needle No. 5 needle), continuous electrospinning for 5h, the fibers ejected and formed from the spinning nozzle in the electrospinning equipment are collected on the collection roller, and the nanofiber non-woven film tube is formed on the collection roller, and the ...

Embodiment 3

[0050] A nanofiber artificial blood vessel is made by the following method:

[0051] (1) dissolving collagen in glacial acetic acid to prepare 20 mL of gelatin solution with a mass fraction of 15%;

[0052] (2) Add 0.001 mL of an aqueous carbodiimide solution with a mass percentage concentration of 60% and mix well to make it moderately pre-crosslinked, and add 5 mL of a 3% heparin sodium aqueous solution to form collagen-heparin Sodium spinning stock solution; the spinning stock solution is loaded into the electrospinning equipment, and the electrospinning process is adopted (process parameters: voltage 15kV, receiving distance 15cm, solution flow rate 0.5mL / h, collection roller speed 100r / min, needle No. 5 needle), continuous electrospinning for 5h, the fibers ejected and formed by the spinning nozzle in the electrospinning equipment are collected on the collection roller, and the nanofiber non-woven film tube is formed on the collection roller, the shaft of the collection r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com