Method for preparing three-dimensional structure Co-MOF/NF supercapacitor electrode material in situ based on foamed nickel

A technology for supercapacitors and electrode materials, applied in the field of electrochemical energy storage, can solve problems such as large contact resistance, insufficient application of active materials, cumbersome electrode preparation process, etc., to reduce contact resistance and simplify the preparation process Easy operation and short reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

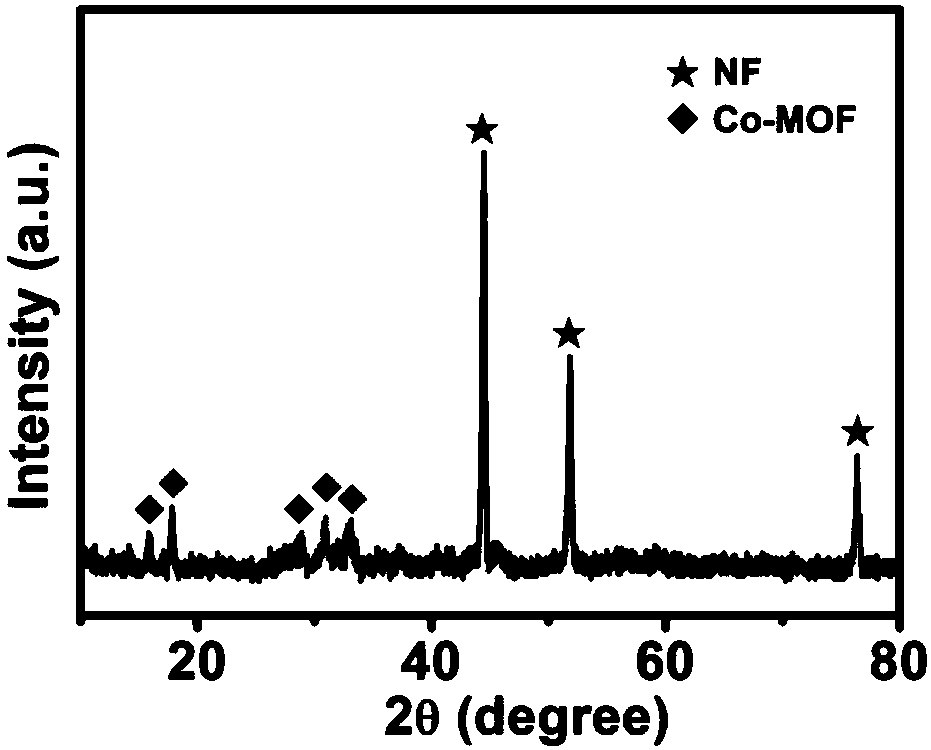

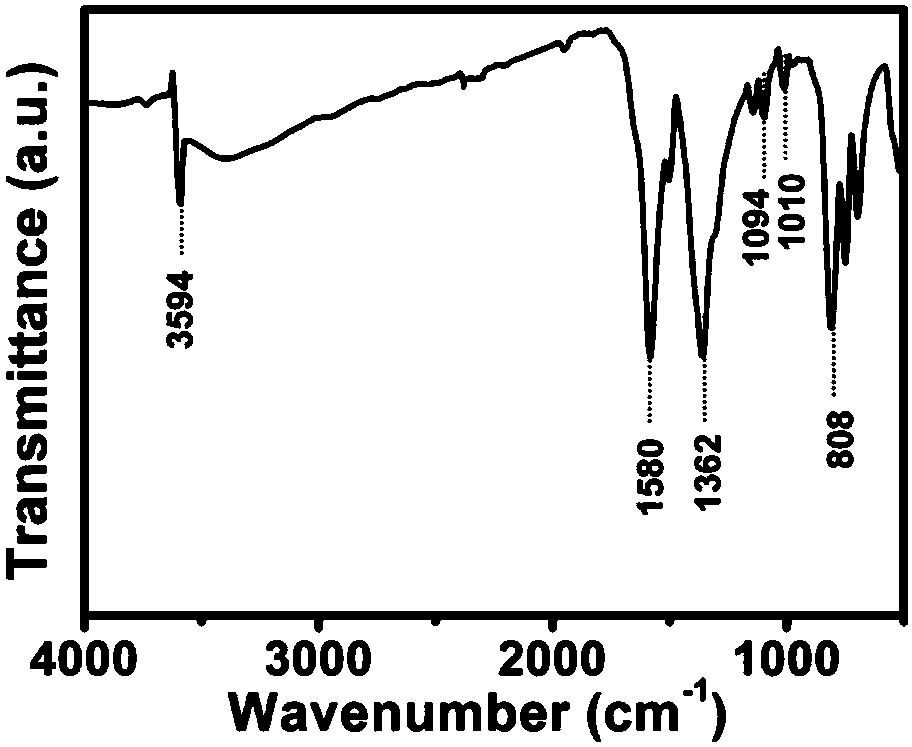

example 1

[0023] (1) Material preparation: 0.291 g cobalt nitrate hexahydrate and 0.166 g terephthalic acid, the molar ratio is 1:1, measure 35 mL N,N-dimethylformamide as solvent, 5 mL absolute ethanol as additive, One piece measures 2×3 cm 2 Nickel foam was pretreated with ethanol, 5% dilute hydrochloric acid and deionized water for 10 min respectively;

[0024] (2) Reaction: Pour the above prepared solution into a 50 mL polytetrafluoroethylene autoclave, then put a piece of processed nickel foam into the autoclave, seal the autoclave, place it in an oven, and Reaction at 125 ℃ for 12 h;

[0025] (3) Washing: After the reaction is completed, cool the polytetrafluoroethylene autoclave to room temperature in the air, take out the nickel foam evenly covered by the dark yellow substance, and wash it with N,N-dimethylformamide and absolute ethanol respectively. rinse three times;

[0026] (4) Drying: The washed product was vacuum-dried at 60 °C for 8 h to obtain the Co-MOF / NF electrode ...

example 2

[0029] (1) Material preparation: 0.582 g cobalt nitrate hexahydrate and 0.332 g terephthalic acid, the molar ratio is 1:1, measure 70 mL N,N-dimethylformamide as solvent, and 10 mL absolute ethanol as additive , a piece with a size of 2×3 cm 2 Nickel foam was pretreated with ethanol, 5% dilute hydrochloric acid and deionized water for 10 min respectively;

[0030] (2) Reaction: Pour the above-mentioned prepared solution into two 100mL polytetrafluoroethylene autoclaves, then put the pre-treated foamed nickel into the autoclave, and seal the autoclave, place it in the oven, React at 125 °C for 12 h;

[0031] (3) Washing: After the reaction is completed, cool the polytetrafluoroethylene autoclave to room temperature in the air, take out the nickel foam evenly covered by the dark yellow substance, and wash it with N,N-dimethylformamide and absolute ethanol respectively. rinse three times;

[0032] (4) Drying: The washed product was vacuum-dried at 60 °C for 8 h to obtain the C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com