Method for preparing petroleum wax hydrofining catalyst

A hydrorefining and catalyst technology, which is applied in petroleum wax refining, catalyst activation/preparation, catalyst carrier, etc., can solve the problems of complex process and difficult operation, and achieve simple preparation process, improved dispersion degree, and increased pore volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

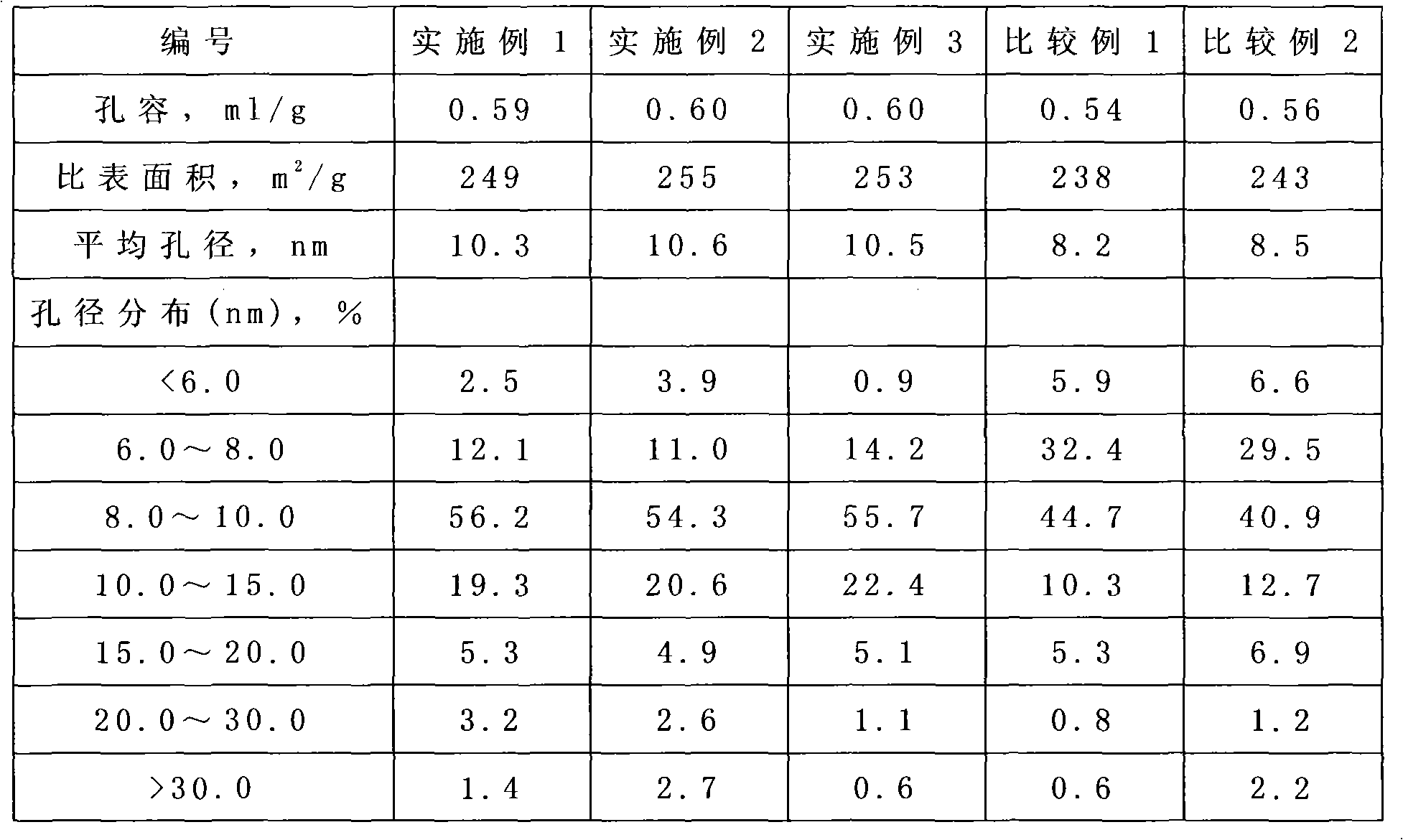

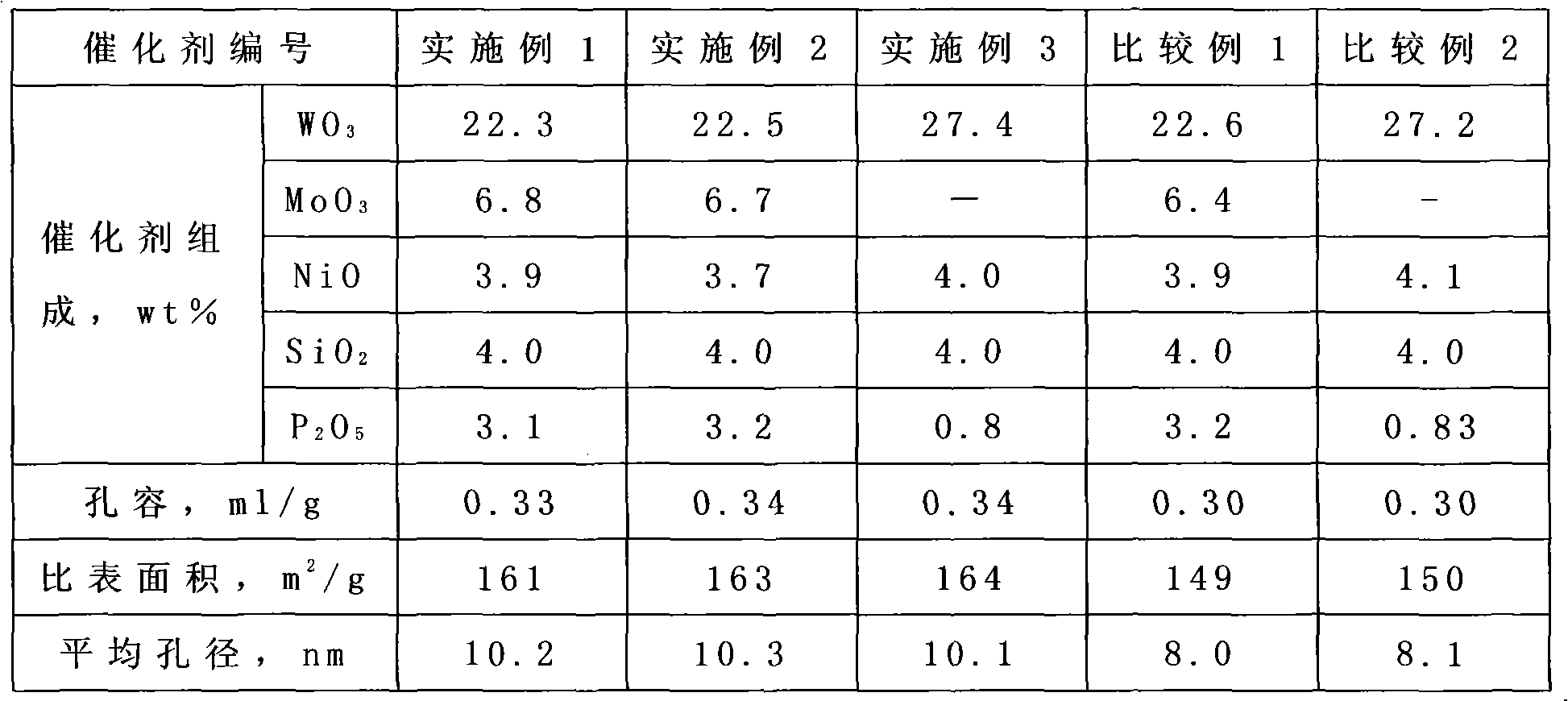

Examples

Embodiment 1

[0025] (1) SiO 2 -P 2 o 5 -Al 2 o 3 Preparation of vector

[0026] Take by weighing 1000g pseudo-boehmite, 30g Tianqing powder, 30g citric acid, 100g silica sol (SiO 2 concentration of 30%), 100g of fatty alcohol ether phosphate, and 700ml of 3-5% dilute nitric acid are mixed evenly, extruded with an extruder, dried at 110°C, and roasted at 650°C under air to obtain SiO 2 -P 2 o 5 -Al 2 o 3 carrier.

[0027] (2) Preparation of W-Mo-Ni-P impregnation solution

[0028] Configure 1000ml solution, weigh 125g molybdenum trioxide (industrial grade) and 60g basic nickel carbonate (industrial grade) into 600ml water, stir well, add 40g phosphoric acid (85%), boil for 2 hours, add 200g nickel nitrate, continue Boil for 15 minutes, cool to room temperature, add 410g of ammonium metatungstate, after all dissolved, add dilute ammonia water to adjust the pH value of the solution to 4.0. Transfer the solution to a volumetric flask, add water to make the volume to 1000ml, and obt...

Embodiment 2

[0032] (1) SiO 2 -P 2 o 5 -Al 2 o 3 Preparation of vector

[0033] Take by weighing 1000g pseudo-boehmite, 30g Tianqing powder, 30g citric acid, 100g silica sol (SiO 2 Concentration: 30%), 120g polyol phosphate ester, 750ml of 3-5% dilute nitric acid are mixed evenly, extruded with extruder, dried at 110°C, and roasted at 650°C under air to obtain SiO 2 -P 2 o 5 -Al 2 o 3 carrier.

[0034] (2) Preparation of W-Mo-Ni-P impregnation solution

[0035] With embodiment 1 (2).

[0036] (3) Preparation of W-Mo-Ni catalyst

[0037] With embodiment 1 (3).

Embodiment 3

[0039] (1) SiO 2 -P 2 o 5 -Al 2 o 3 Preparation of vector

[0040] Take by weighing 1000g pseudo-boehmite, 30g Tianqing powder, 30g citric acid, 100g silica sol (SiO 2 Concentration: 30%), 140g of polyol phosphate, 730ml of 3-5% dilute nitric acid are mixed evenly, extruded with extruder, dried at 110°C, and roasted at 650°C under air to obtain SiO 2 -P 2 o 5 -Al 2 o 3 carrier.

[0041] (2) Preparation of W-Ni catalyst.

[0042] Weigh 500gSiO2 2 -P 2 o 5 -Al 2 o 3 Carrier, with a certain amount of ammonium metatungstate and nickel nitrate aqueous solution (WO 3 Concentration of 70g / 100ml; NiO concentration of 20g / 100ml) saturated spray soaking for 1 hour, drying at 110°C, and then roasting at 450°C to obtain the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com