Method for promoting healing of crackles in gelatin casting molding biscuit

A technology of pouring molding and gelling, which is applied in the direction of ceramic molding machines, manufacturing tools, etc., to achieve the effect of easy realization, easy access, uniform and complete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

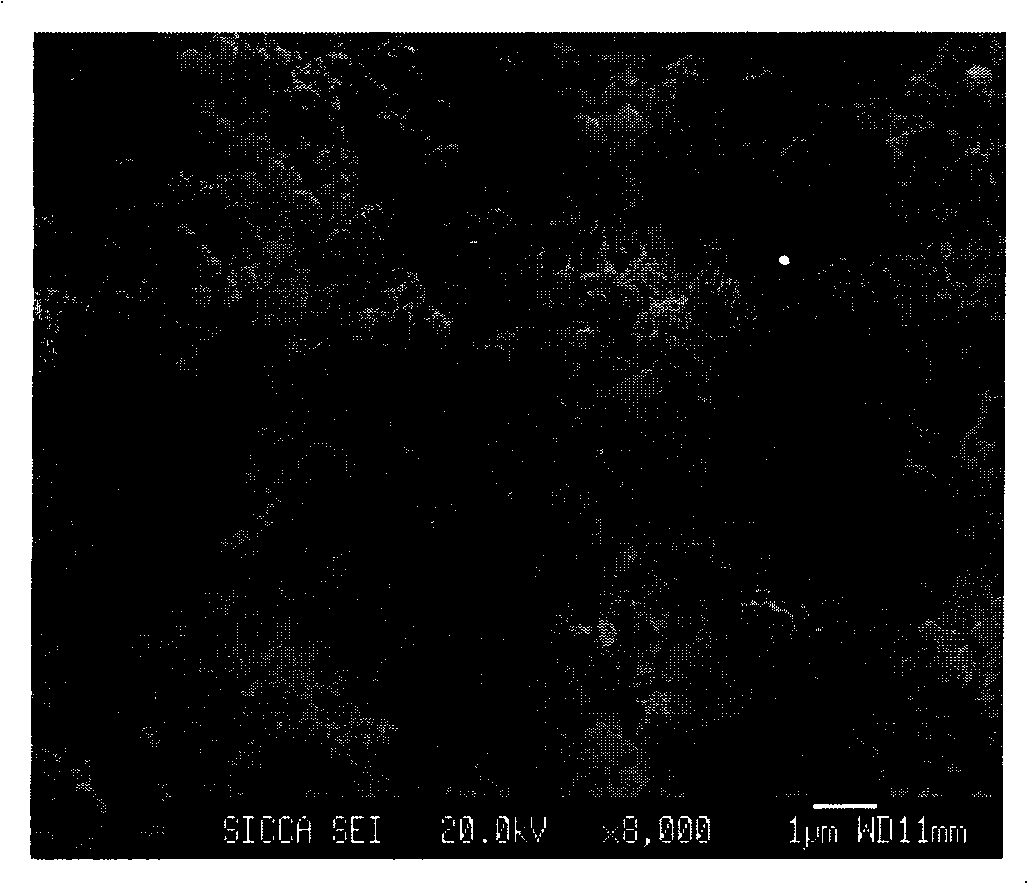

Image

Examples

Embodiment 1

[0014] The monomer acrylamide was dissolved in deionized water to make a 15wt% solution, and the cross-linking agent N,N'-methylenebisacrylamide (MBAM) was added. The ratio of crosslinking agent to monomer is 1:6. The dispersant tetramethylammonium hydroxide (TMAH) was then added to prepare a premix. Add silicon carbide powder and ball mill to obtain a slurry with a solid content of about 50vol%, and the viscosity of the slurry is about 300-600mPa.s. Add the initiator azo[2-(2-imidazolin-2-yl)]propane hydrochloride (AZIP·2HCl)), wherein the addition amount of the initiator is 1 / 10-1 / 15 of the monomer. Stir vigorously and defoam after addition. Then pour into molds as needed. Curing in the temperature range of 40-60 ℃ for 30-60min. Take it out and get a wet biscuit after demoulding. Then put the wet biscuit in a constant temperature and humidity oven, and dry it for 24-96 hours at 50-75°C and a relative humidity of 80-95%, and finally use a multi-step drying method to obta...

Embodiment 2

[0016]The monomer methacrylamide was dissolved in deionized water to make a 15wt% solution, and the cross-linking agent N,N'-methylenebisacrylamide (MBAM) was added. The ratio of crosslinking agent to monomer is 1:3. A dispersant polyethyleneimine (PEI) was then added to prepare a premix. Add titanium carbide powder and ball mill to obtain a slurry with a solid content of about 50vol%, and the viscosity of the slurry is about 300-600mPa.s. Ammonium persulfate (APS) is added as an initiator, wherein the amount of the initiator added is 1 / 10-1 / 15 of the monomer. Stir vigorously and defoam after addition. Then pour into molds as needed. Curing in the temperature range of 40-50 ℃ for 20-60min. Take it out and get a wet biscuit after demoulding. Then put the wet biscuit in a constant temperature and constant humidity oven, and dry it for 24-96 hours at 50-70°C and a relative humidity of 80-95%, and finally obtain a defect-free gel-cast bisque by a multi-step drying method.

Embodiment 3

[0018] The monomer N,N-dimethylacrylamide was dissolved in deionized water to make a 15wt% solution, and the cross-linking agent N,N'-methylenebisacrylamide (MBAM) was added. The ratio of crosslinking agent to monomer is 1:6. Then add the dispersant tetramethylammonium hydroxide to prepare the premix. Add boron carbide powder and ball mill to obtain a slurry with a solid content of about 57vol%, and the viscosity of the slurry is about 400-600mPa.s. Azo(2-mimidylpropane) hydrochloride (AZAP·2HCl) is added as an initiator, wherein the amount of the initiator added is 1 / 10-1 / 15 of the monomer. Stir vigorously and defoam after addition. Then pour into molds as needed. Curing in the temperature range of 40-60°C for 30-90min. Take it out and get a wet biscuit after demoulding. Then put the wet green body in a constant temperature and constant humidity oven, and dry it for 60-96 hours at 60-80° C. and a relative humidity of 85-95%, and finally adopt a multi-step drying method t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com