Decision method for testing in-service water turbine runner crackle

A judgment method and hydraulic turbine technology, applied in the direction of optical testing for flaws/defects, etc., can solve the problems of long maintenance period, low efficiency, and failure to consider the formation mechanism of runner cracks, etc., and achieve good economic value and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

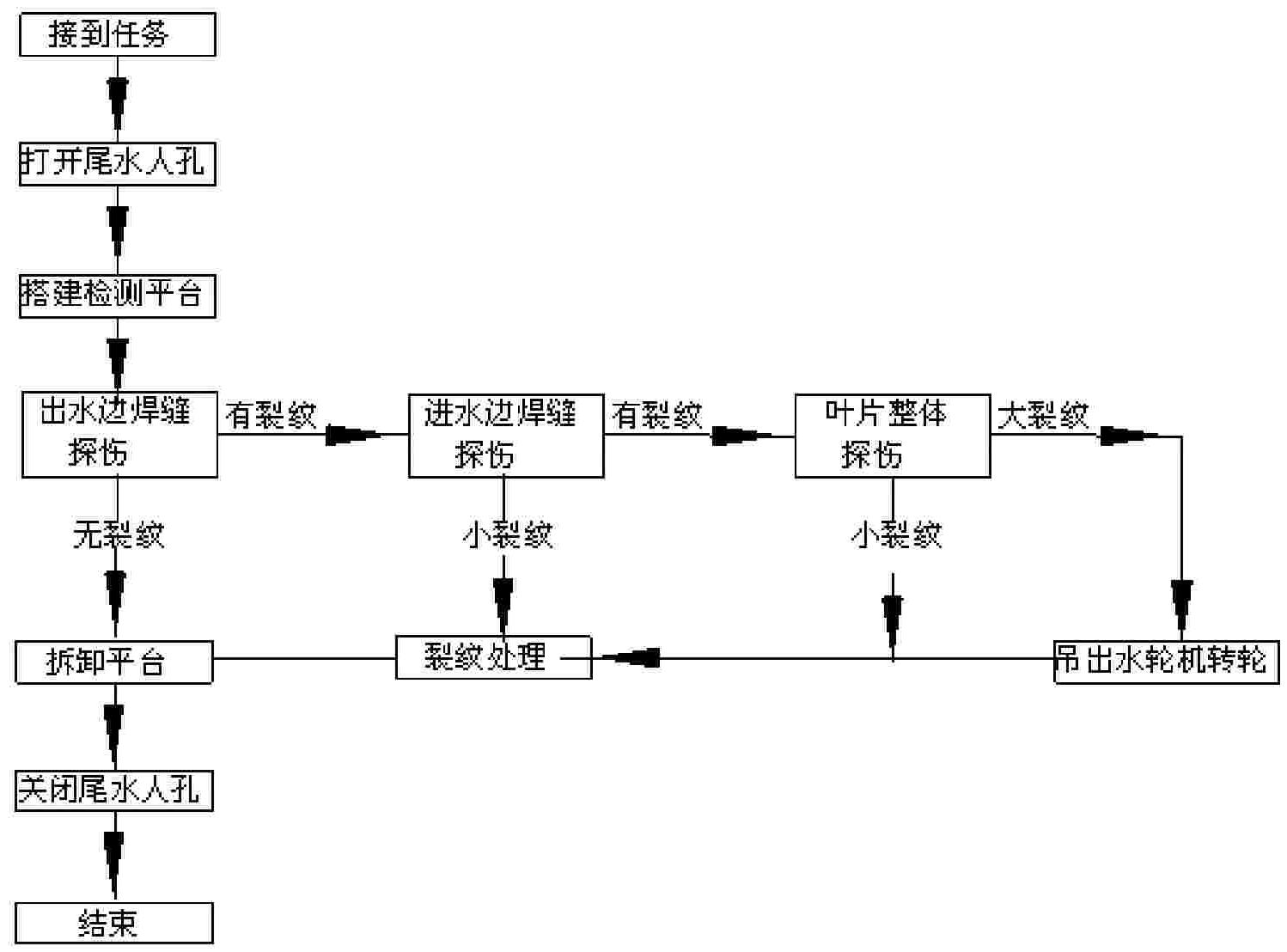

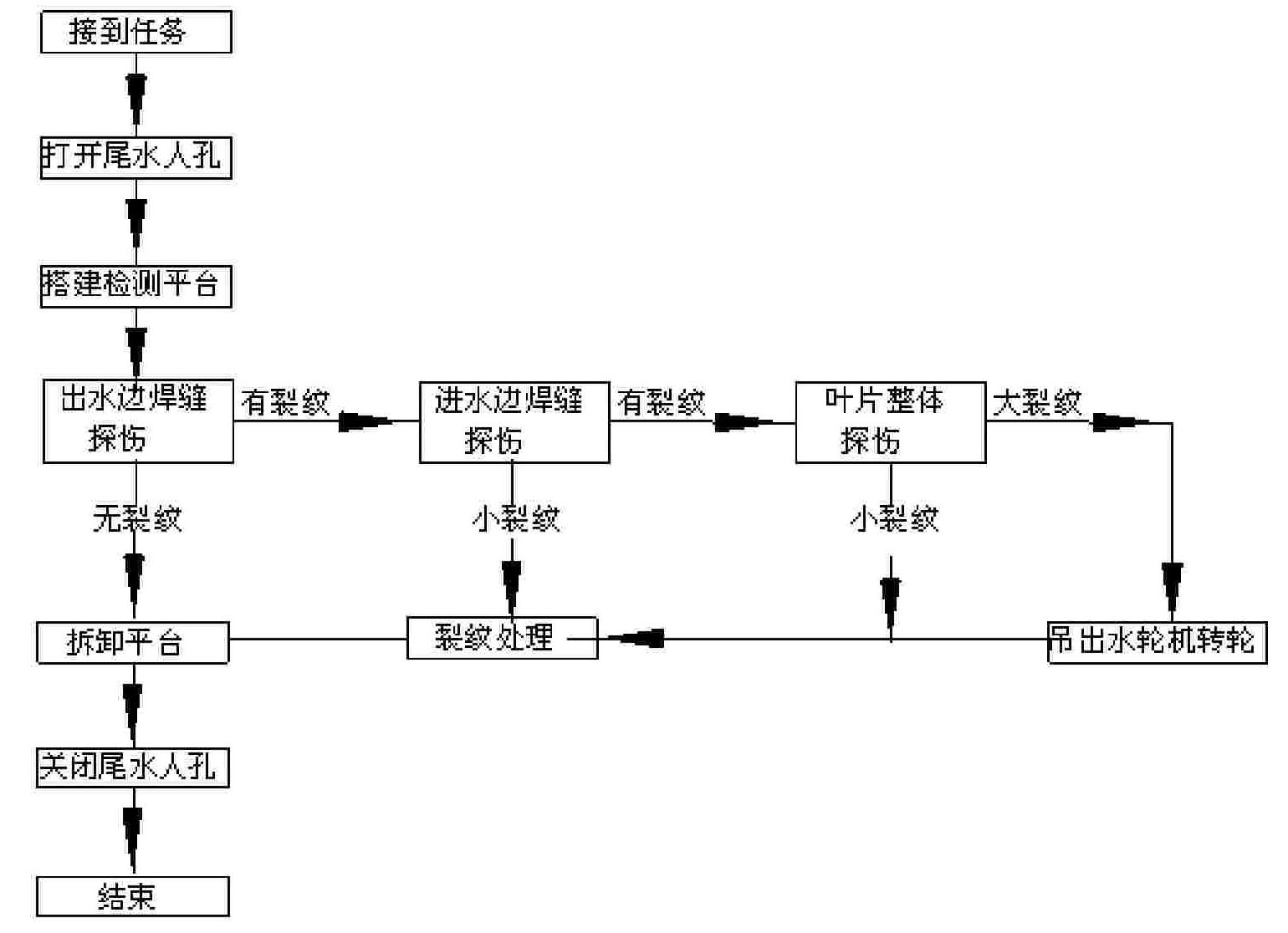

[0030] Embodiment 1: after receiving detection task, detect according to the following steps,

[0031] a. Open the manhole of the draft pipe of the hydraulic turbine, and build a detection platform in the manhole;

[0032] b. Use the penetrant detection method to detect the flaws of the outlet edge weld of the runner blade. If there is no crack, enter the c step, and if there is a crack, enter the d step; the detection process of the penetrant detection method is to clean the detection part first, and then apply Penetrant, remove excess penetrant after 8 to 10 minutes, apply imaging agent for observation and detection, and wash after the detection.

[0033] c. Disassemble the detection platform and close the turbine manhole;

[0034] d. Carry out flaw detection to the water inlet edge weld seam of runner blade, if there is no crack in the water inlet edge weld seam of runner blade, repair the water outlet edge weld seam of runner blade, enter c step after repairing; The meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com