Method for cold arc welding of titanium and titanium alloy

A titanium alloy and arc welding technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as cold cracks and large residual stress in welds, achieve stable welding process, reduce residual stress, reduce The effect of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

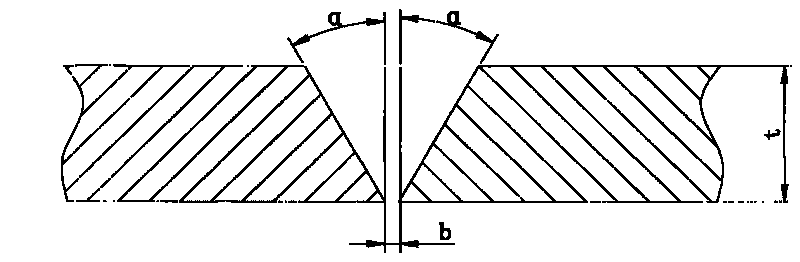

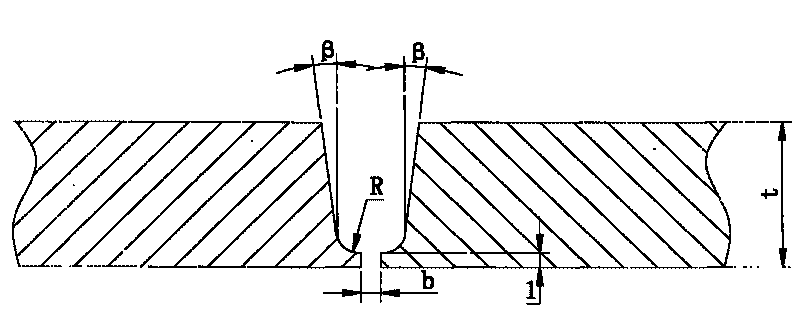

[0046] Using the titanium and titanium alloy cold arc welding method of the present invention, the welding of titanium and titanium alloy shroud simulation parts has been carried out, and the welding seam structure forms include 4mm+4mm plate thickness butt weld seam, 4mm+16mm plate thickness fillet weld seam , 16mm+16mm plate thickness fillet welds, V-shaped grooves are used for butt welding, groove surface angle α=30°groove gap b=2mm. The whole welding process is stable, the welding efficiency is high, and the weld seam quality meets the requirements of the titanium alloy shroud manufacturing standard. The welding parameters used in the welding process are as follows:

[0047] Welding Wire Feed Speed Welding Speed Arc Length Correction Pulse Wire Gauge Shielding Gas

[0048] Location

[0049] Mode m / min cm / min % Correction division mm type

[0050] 1.3 65%He+35

[0051] Butt welding CMT+P 6.0~6.8 30~35 10~15...

Embodiment 2

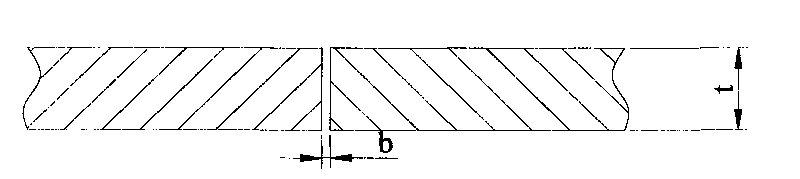

[0061] Using the titanium and titanium alloy cold arc welding method of the present invention, carried out 1mm thick, 300mm long, 150mm wide test plate flat welding position butt welding test, adopt I type groove, groove gap b=0. The welding process is stable, the back of the weld is well formed, and the internal quality of the weld meets the requirements of JB / T4730.2-2005 level II. The welding parameters used in the welding process are as follows:

[0062] Welding Wire Feed Speed Welding Speed Arc Length Correction Dynamic Wire Gauge Shielding Gas

[0063] Mode m / min cm / min % Correction division mm type

[0064] 70%He+30

[0065] CMT 4.0 50~55 15 1.2 Φ1.2

[0066] %Ar

Embodiment 3

[0068] Using the titanium and titanium alloy cold arc welding method of the present invention, carried out 2mm thick, 300mm long, 150mm wide test plate flat welding position butt welding test, adopt V-shaped groove, groove surface angle α=45 °, groove Gap b=1mm. The welding process is stable, the back of the weld is well formed, and the internal quality of the weld meets the requirements of JB / T4730.2-2005 level II. The welding parameters used in the welding process are as follows:

[0069] Welding Wire Feed Speed Welding Speed Arc Length Correction Dynamic Wire Gauge Shielding Gas

[0070] Mode m / min cm / min % Correction division mm type

[0071] 70%He+30

[0072] CMT 7.0 40~45 15 1.5 Φ1.2

[0073] %Ar

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com