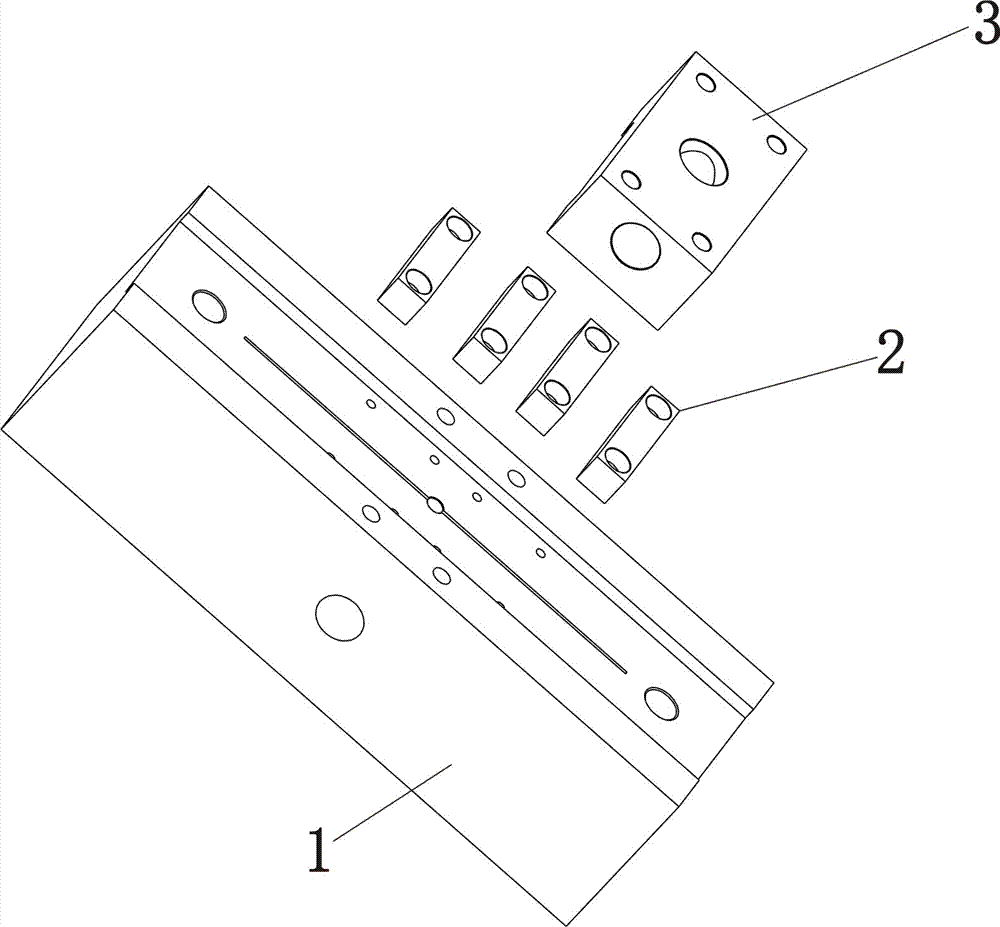

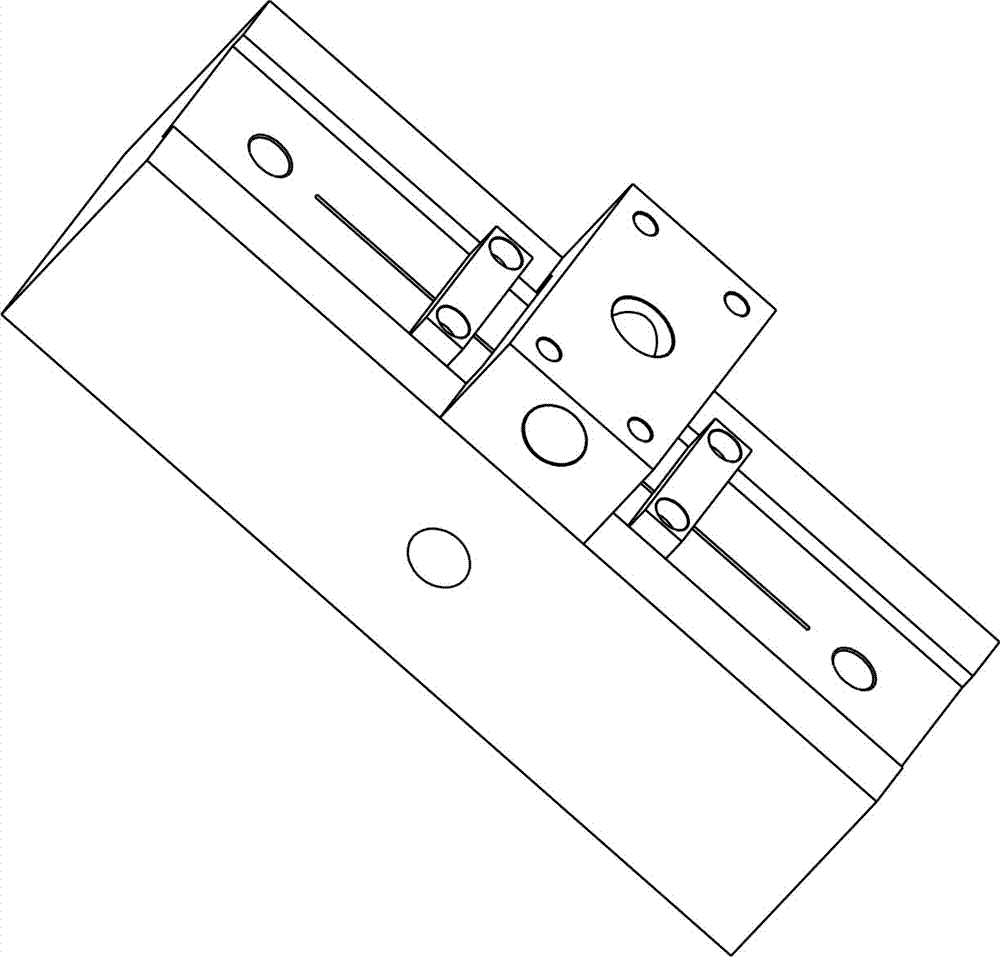

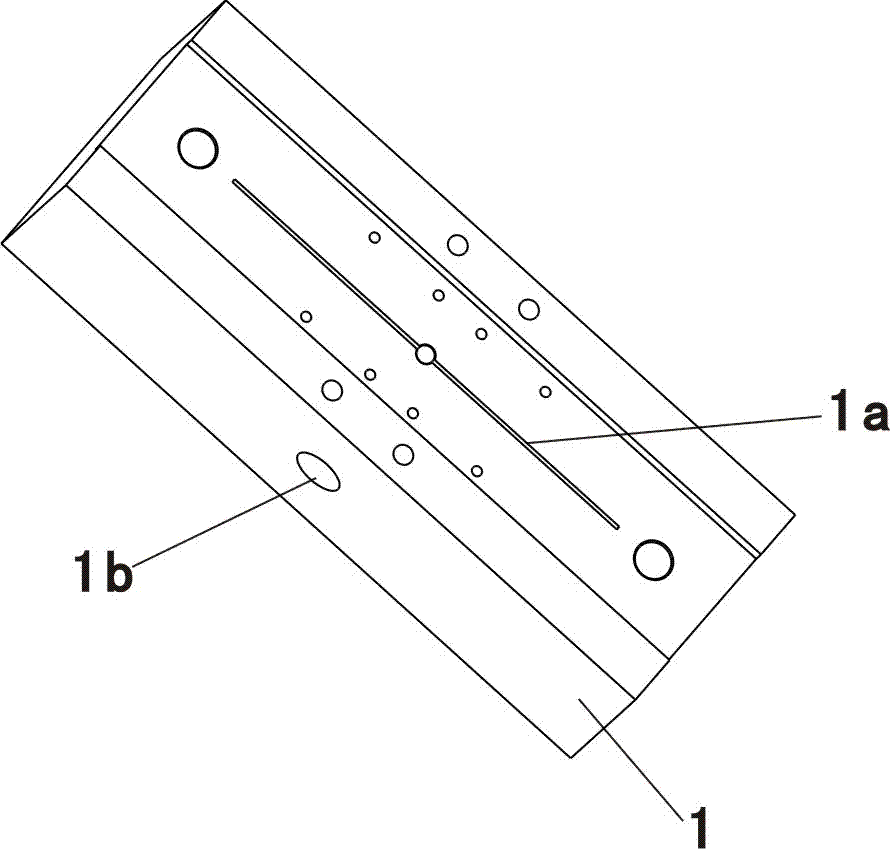

Dissimilar material connecting method of nickel titanium shape memory alloy and copper alloy and clamp thereof

A memory alloy and connection method technology, applied in manufacturing tools, welding equipment, welding equipment, etc., can solve problems such as high resistivity, difficulty in meeting the performance requirements of electronic products with a single material, large differences in melting point and coefficient of linear expansion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, adopt the method of the present invention to carry out the laser welding of nickel-titanium alloy wire and red copper strip. The diameter of the nickel-titanium alloy wire is 0.70mm, and the interface size of the copper strip is 2.00mm (width)*0.50mm (thickness). Put the nickel-titanium alloy wire on top of the copper strip, press it with a self-made fixture (without leaving a gap), and use a pulsed laser heat source to melt the nickel-titanium alloy wire and part of the brass strip to form a lap joint of dissimilar materials. Laser welding process parameters: peak power 2.2KW, pulse width 20ms, pulse energy 26.9J; solder joint overlap rate 60%; shielding gas (Ar) flow rate 40 CFH; post-weld heat treatment temperature: 400°C, holding time: 20min. The shear force of the laser lap joint of nickel-titanium alloy wire-brass strip dissimilar materials can reach 266N, and the deformation recovery rate can reach 92%.

Embodiment 2

[0032]Embodiment 2, adopt the method of the present invention to carry out the laser welding of nickel-titanium alloy strip material and brass strip material. The interface size of the nickel-titanium alloy strip is 2.00mm (width)*0.40mm (thickness), and the interface size of the brass strip is 2.00mm (width)*0.50mm (thickness). Put the brass strip on the upper end, press it with a self-made fixture (without leaving a gap), and use a pulsed laser heat source to melt the brass strip to form a lap joint of brass-nickel-titanium alloy dissimilar materials. Laser welding process parameters: peak power 2.4KW, pulse width 30ms, pulse energy 36.6J; solder joint overlap rate 50%; shielding gas (Ar) flow rate 40 CFH; post-weld heat treatment temperature: 400 ° C, holding time: 10 min. The shear force of the laser lap joint of nickel-titanium alloy wire-brass strip dissimilar materials can reach 242N, and the deformation recovery rate can reach 90%.

Embodiment 3

[0033] Embodiment 3, adopt the method of the present invention to carry out the laser welding of nickel-titanium alloy wire and red copper wire. The diameter of the nickel-titanium alloy wire is 0.40mm, and the diameter of the copper wire is 0.40mm. The nickel-titanium alloy wire and the red copper wire are placed in parallel, pressed with a self-made fixture (without leaving a gap), and a pulsed laser heat source is used to melt and connect the interface strips to form a butt welded joint of dissimilar materials. Laser welding process parameters: peak power 1.6KW, pulse width 20ms, pulse energy 18.8J; solder joint overlap rate 60%; shielding gas (Ar) flow rate 30L / min; post-weld heat treatment temperature: 450-500 ℃, holding time: 10 min. The tensile strength of the laser lap joint of nickel-titanium alloy wire-brass strip dissimilar materials can reach more than 260 Mpa, and the temperature hysteresis is 12°C lower than that of the nickel-titanium shape memory alloy base ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com