Laser welding method for aluminum alloy shell of automobile power battery

A technology for automotive power batteries and aluminum alloy casings, applied in the field of material processing, can solve problems such as low positioning accuracy, prone to welding deviation, air holes, arc craters, unreasonable selection of laser welding process parameters, etc., and achieve high positioning accuracy, Beautiful shape and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, comprises the following steps:

[0023] Step 1, battery module casing material selection and initial positioning;

[0024] Step 2, the robot is equipped with a galvanometer for laser welding.

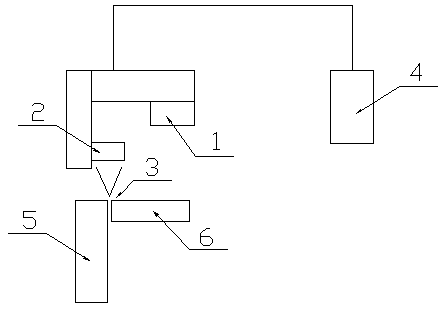

[0025] Step 1: Material selection and initial positioning of the battery module shell. The clamping process uses a magnetic switch to detect the state of the cylinder and feeds back to the controller 4. The controller 4 controls the cylinder to clamp the corresponding part. The corresponding part refers to the battery The module end plate 5 and the module side plate 6 reach the predetermined position of the tooling fixture respectively. The battery module end plate 5 used: the material is 3 series aluminum alloy, and the size is 149.3mm×16.7mm×94.7mm; the module side plate 6 : The material is 3 series aluminum alloy, the size is 515.2mm×3.0mm×105.4mm, wherein, the butt joint gap between the battery module end plate 5 and the module side plate 6 is less than 0.1mm, ...

Embodiment 2

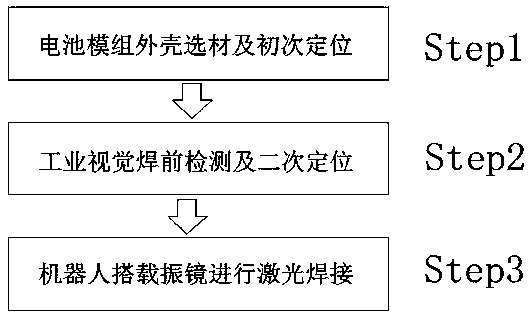

[0029] Embodiment 2, comprises the following steps:

[0030] Step 1, battery module casing material selection and initial positioning;

[0031] Step 2, industrial vision pre-weld inspection and secondary positioning;

[0032] Step 3, the robot is equipped with a galvanometer for laser welding.

[0033] Step 1: Material selection and initial positioning of the battery module shell. The clamping process uses a magnetic switch to detect the state of the cylinder and feeds back to the controller 4. The controller 4 controls the cylinder to clamp the corresponding part. The corresponding part refers to the battery The module end plate 5 and the module side plate 6 reach the predetermined position of the tooling fixture respectively. The battery module end plate 5 used: the material is 3 series aluminum alloy, and the size is 149.3mm×16.7mm×94.7mm; the module side plate 6 : The material is 3 series aluminum alloy, the size is 515.2mm×3.0mm×105.4mm, wherein, the butt joint gap betw...

Embodiment 3

[0038] Embodiment 3, comprises the following steps:

[0039] Step 1, battery module casing material selection and initial positioning;

[0040] Step 2, industrial vision pre-weld inspection and secondary positioning;

[0041] Step 3, the robot is equipped with a galvanometer for laser welding.

[0042]Step 1: Material selection and initial positioning of the battery module shell. The clamping process uses a magnetic switch to detect the state of the cylinder and feeds back to the controller 4. The controller 4 controls the cylinder to clamp the corresponding part. The corresponding part refers to the battery The module end plate 5 and the module side plate 6 reach the predetermined position of the tooling fixture respectively. The battery module end plate 5 used: the material is 3 series aluminum alloy, and the size is 149.3mm×16.7mm×94.7mm; the module side plate 6 : The material is 3 series aluminum alloy, the size is 515.2mm×3.0mm×105.4mm, wherein, the butt joint gap betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com