Method and device for welding inside fillet welds of T-shaped joints through infilling-type friction-stir welding

A friction stir welding and filling technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of the failure of the external pad technology, the high cost of the external pad, and the low utilization rate. Increased strength, strong versatility, and increased weld reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] The present invention provides a friction plane for the shaft shoulder of the stirring head 6 by using specific fixtures and process auxiliary pads 5 to cooperate with the actual weldment, so as to realize the friction stir welding welding of the inner fillet weld of the T-shaped joint.

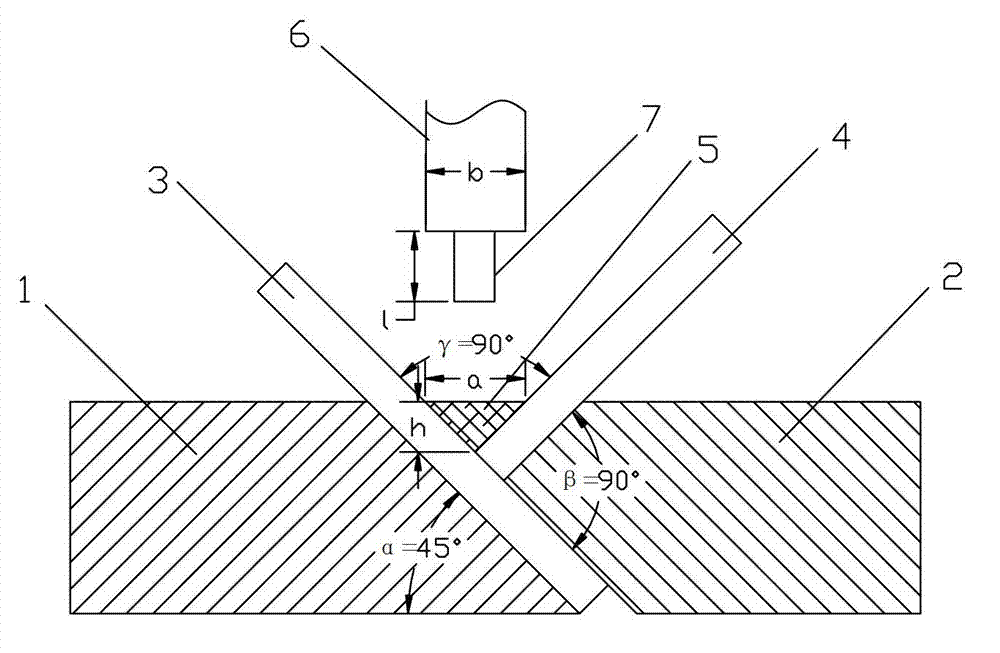

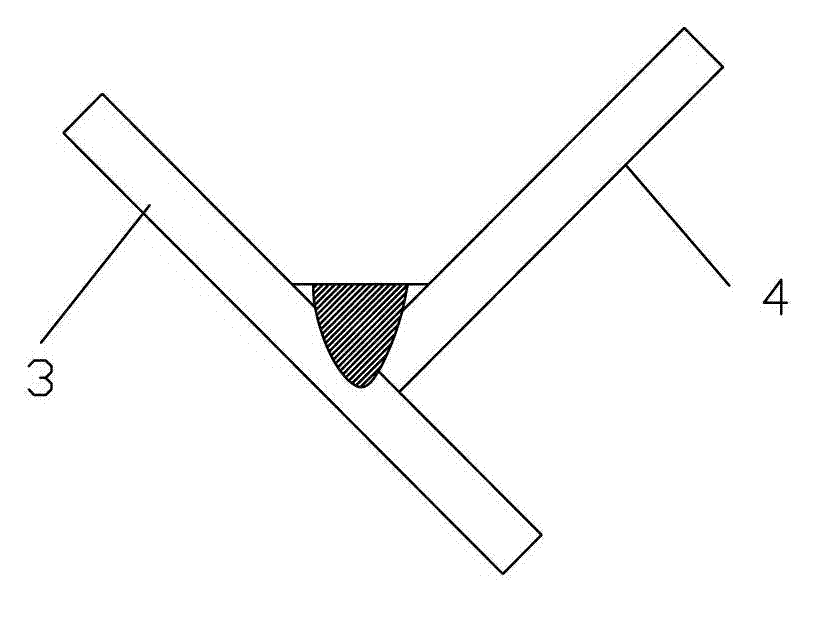

[0016] Such as figure 1 As shown, the device used to realize the welding method in the present invention includes a fixture, a stirring head 6 with a stirring needle 7, a process auxiliary pad 5 used to fill a T-joint and is homogeneous with the base material, and the fixture includes a corresponding And the first split body 1 and the second split body 2 can slide relative to each other. The side of the first split body 1 contacting the base material is at an angle of α=45° to the horizontal plane, and the angle between the two slopes of the second split body 2 contacting the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com