Underwater steel construction crackle friction stitch welding renovation method and equipment

A friction stitch welding and repair method technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of long-term reliability of mechanical connectors not eliminated, difficult arc stability, accurate positioning and installation difficulties, etc. , to achieve the effect of efficient and reliable welding method, easy maintenance and repair, and excellent welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

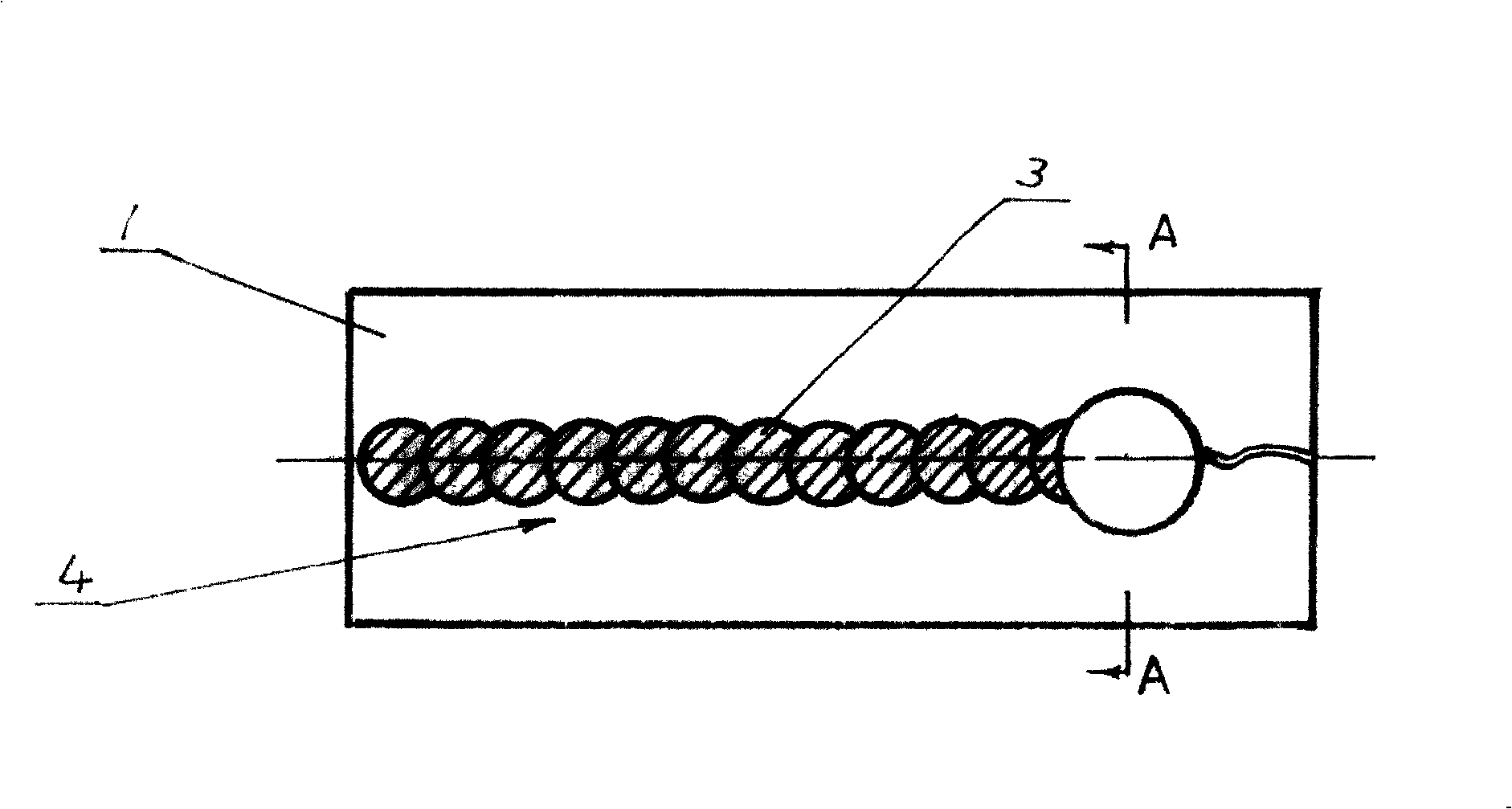

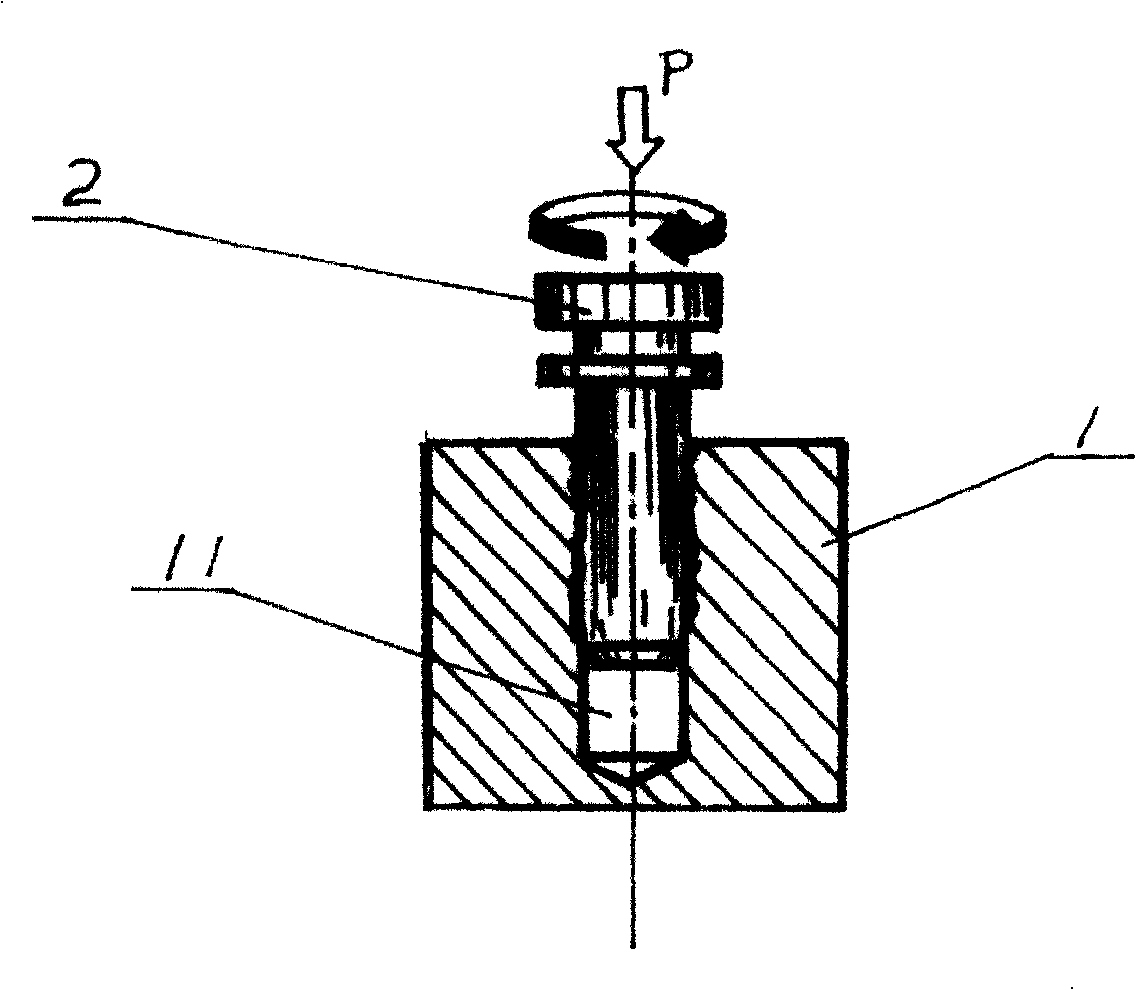

[0019] A method for repairing cracks in an underwater steel structure by friction stitch welding, the method comprising the following steps: drilling a welding hole 11 on a body to be welded 1, using a stopper rod 2 with a diameter slightly smaller than the welding hole 11 to rotate at a high speed in the welding hole 11, and The pressure P is applied in the axial direction, so that the contact surface between the stopper rod 2 and the welding hole 11 is heated and melted, and a welding unit 3 is formed by a crystallization metallurgical reaction, and a series of overlapping welding units 3 are completed to form a complete lap welding seam 4.

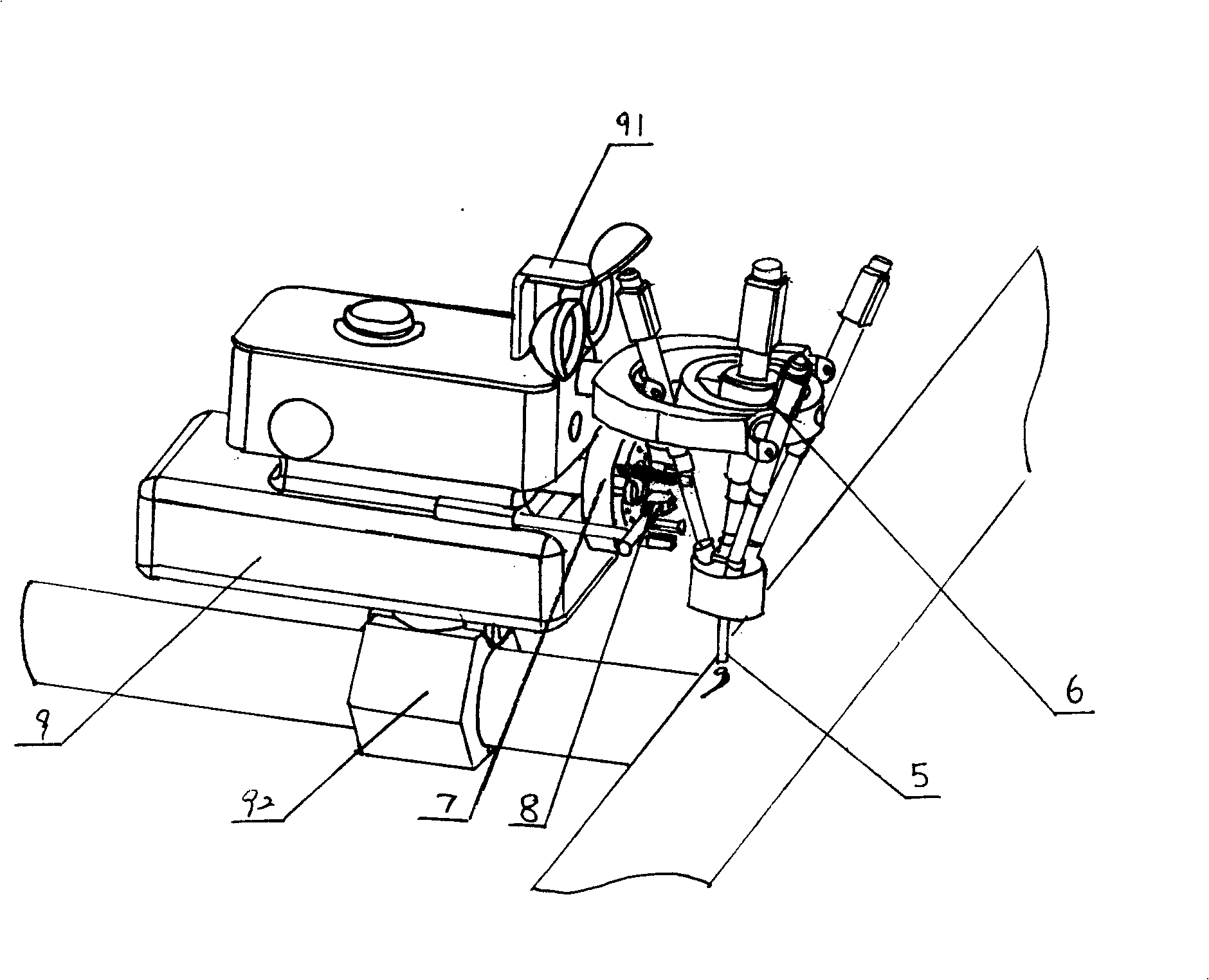

[0020] The equipment used to realize the method of the present invention mainly includes the friction spindle head 5 located under water, the underwater operation manipulator 6, the automatic tool magazine 7, the tool changing mechanism 8 and the underwater remote control robot 9, and the hydraulic power system located on the water, Ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com