Preparation method of vale control lead-acid accumulator green plate without crackles

A technology of lead-acid batteries and raw plates, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of increased production costs, little effect, increased curing time, etc., to improve the qualified rate of sub-plates, reduce production costs, and considerable economy benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

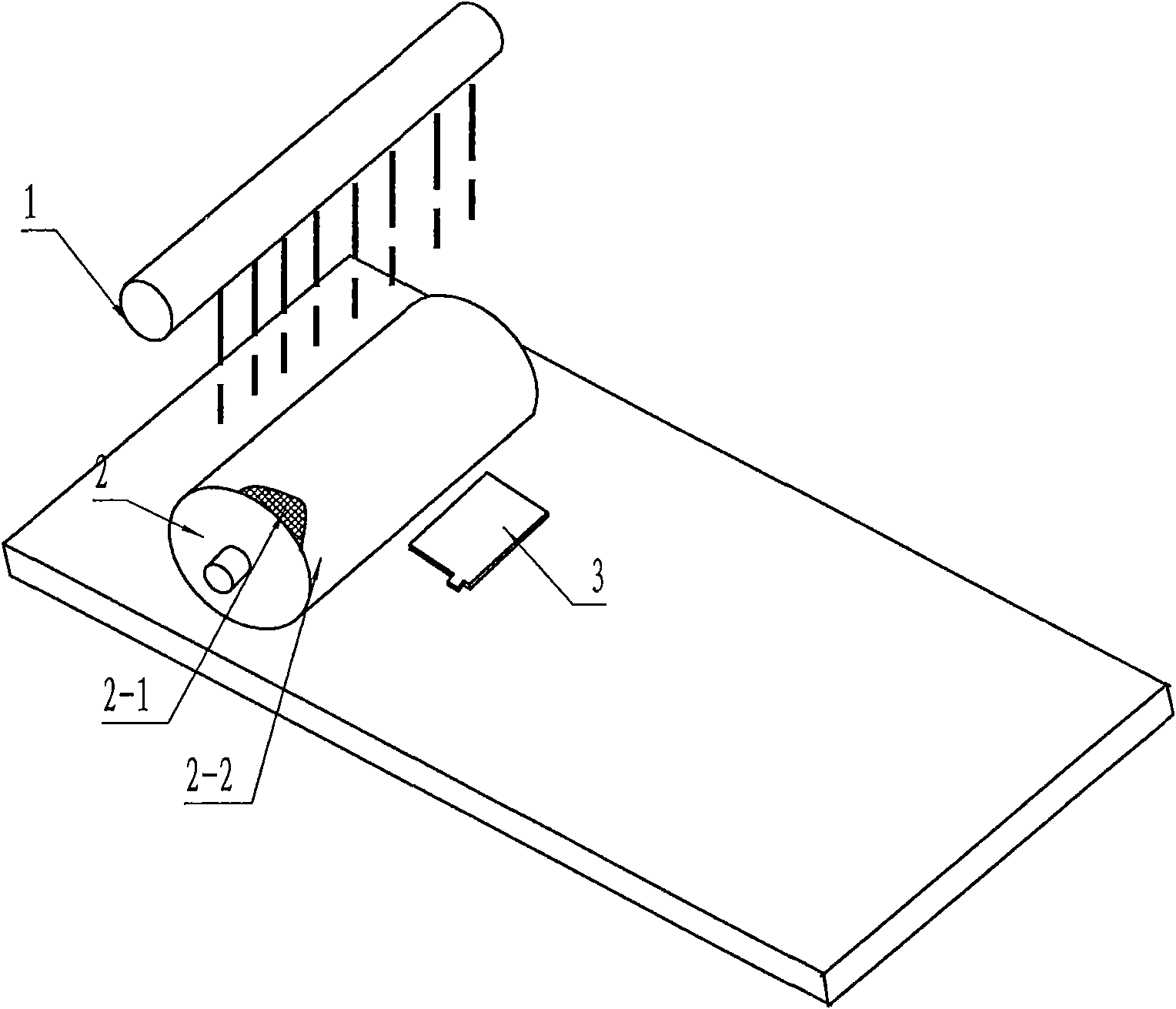

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the lead oxide content of the lead powder used in the paste is 65%, and the apparent density of the paste is 4.10g / cm 3 , the paste after the green plate adopts 1.150g / cm 3 The dilute sulfuric acid is subjected to rolling acid treatment, and the plate enters the curing and drying room within 10 minutes after rolling and acid treatment. The curing and drying temperature is controlled at 45°C and the humidity is controlled at 85%.

Embodiment 2

[0019] Embodiment 2: the lead oxide content of the lead powder used in the paste is 75%, and the apparent density of the paste is 4.30g / cm 3 , the paste after the green plate adopts 1.150g / cm 3 The dilute sulfuric acid is subjected to rolling acid treatment, and the plate enters the curing and drying room within 10 minutes after rolling and acid treatment. The curing and drying temperature is controlled at 50°C and the humidity is controlled at 90%.

Embodiment 3

[0020] Embodiment 3: the lead oxide content of the lead powder used in the paste is 70%, and the apparent density of the paste is 4.50g / cm 3 , the paste after the green plate adopts 1.150g / cm 3 The dilute sulfuric acid is subjected to rolling acid treatment, and the plate enters the curing and drying room within 10 minutes after rolling and acid treatment. The curing and drying temperature is controlled at 40°C and the humidity is controlled at 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com