Non-destructive inspection unit of cup-shaped forge piece

A non-destructive testing and forging technology, applied in the direction of material magnetic variables, can solve the problems of high safety risk, undetectable, high quality cost, etc., and achieve the effect of high reliability and stable residual magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

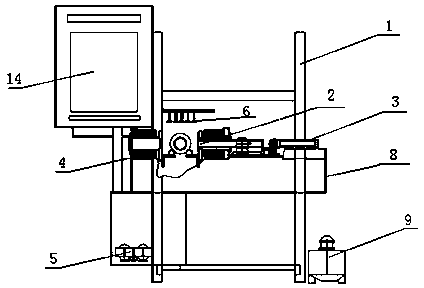

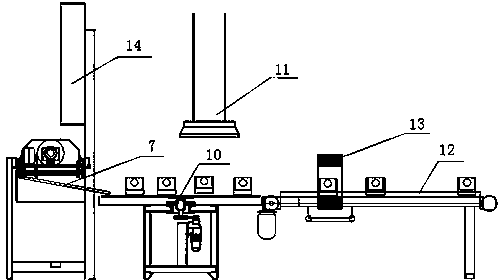

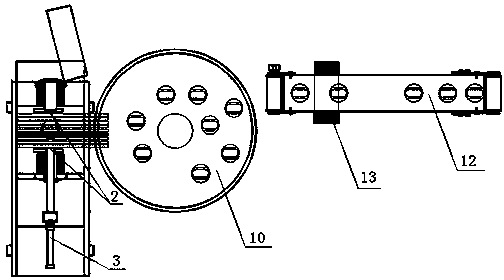

[0030] See Figure 1-Figure 5 , a non-destructive testing unit for cup-shaped forgings, including primary non-destructive testing equipment and secondary non-destructive testing equipment arranged in sequence, both the primary non-destructive testing equipment and the secondary non-destructive testing equipment include magnetizing equipment, fluorescent The detection table and the demagnetization conveying device, and the electrical control cabinet 14 connected with the magnetization equipment, the fluorescence detection device, and the demagnetization conveying device; wherein, the fluorescence detection device and the demagnetization conveying device of the primary non-destructive testing equipment and the secondary non-destructive testing equipment are all arranged on the belt There is a ventilator 16 in the detection dark shed 15, and the detection dark shed 15 is located behind the fluorescent detection device and is also provided with a grinding conveyor belt 17, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com