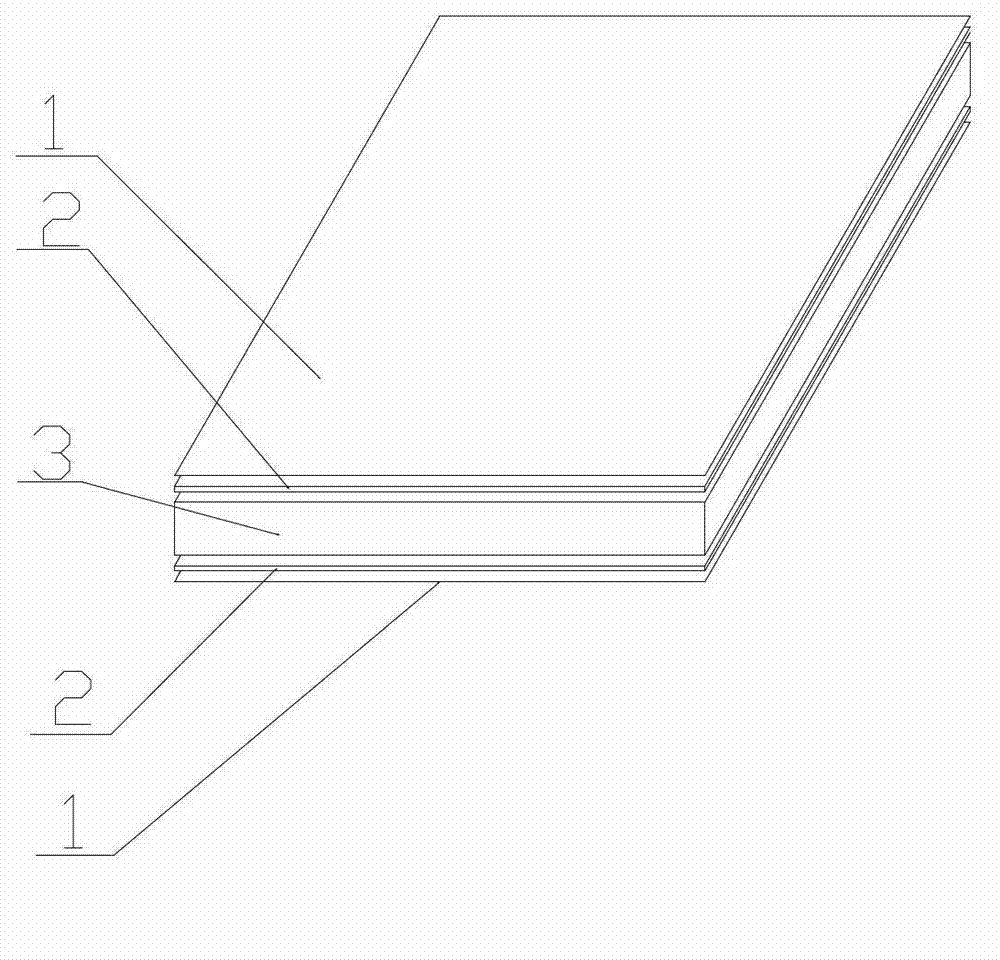

Three-hot-pressing and two-sanding eucalyptus poplar composite artificial board and method for manufacturing same

A manufacturing method and technology for wood-based panels, which are applied in manufacturing tools, chemical instruments and methods, and wood-layered products, etc., can solve the problems of unsightly surface texture, poor veneer quality, and increased furniture costs, so as to reduce release and ensure The effect of cleaning and reducing the cost of furniture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

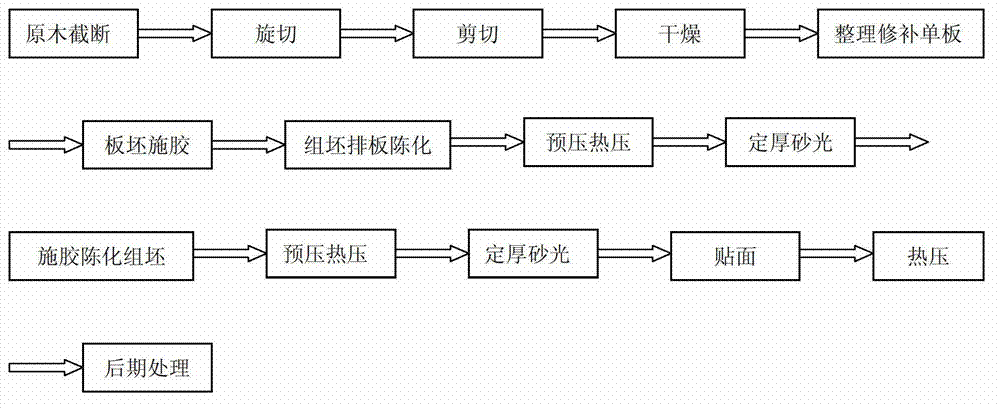

[0035] Cut eucalyptus logs and poplar logs into 1320mm-long wood sections with a chainsaw machine, and process them into eucalyptus veneers with a thickness of 1.7mm and poplar sheets with a thickness of 0.6mm by rotary cutting and cutting with a shaft-free rotary cutter Then use a mesh belt type veneer dryer to dry and process the veneer, and control the moisture content of the veneer to 10%; then repair some of the veneers by hand, stack the veneers according to different tree species, and then take the eucalyptus single The board is sizing by roller sizing method, the adhesive used is E1 grade urea-formaldehyde resin, the solid content is 65%, and the sizing amount is 340g / ㎡; the eucalyptus veneer after gluing is arranged vertically according to the interlayer fiber direction to assemble the blanks. Assemble the eucalyptus veneer with 3 layers, and then age the slab closed for 40 minutes until the moisture content of the slab reaches 13%; send the slab to a cold press for pr...

Embodiment 2

[0037] The eucalyptus log and the poplar log are cut and processed into wood segments with a chainsaw, and processed into eucalyptus veneer with a thickness of 2.0mm and poplar veneer with a thickness of 0.6mm by rotary cutting and cutting by a rotary cutter; The veneer is dried and processed with a mesh belt veneer dryer, and the moisture content of the veneer is controlled to be 7%. Then, some veneers are repaired manually, and the veneers are stacked according to different tree species, and then the eucalyptus veneers are manually applied. Glue, the adhesive used is melamine-modified urea-formaldehyde resin, with a solid content of 60%, and a sizing amount of 350g / ㎡; the eucalyptus veneers after gluing are arranged vertically according to the interlayer fiber direction to form blanks, and each group contains 6 layers of eucalyptus veneer, then the slab is closed-type aging for 40 minutes until the moisture content of the slab reaches 14%; the slab is sent to the cold press f...

Embodiment 3

[0039]Go to the veneer factory to buy a batch of high-quality 2.2mm thick eucalyptus veneer and 0.6mm thick poplar veneer with a moisture content of 15% of a certain specification, and then take the eucalyptus veneer and apply glue manually. The adhesive used is E1 grade urea-formaldehyde resin. The solid content is 65%, and the sizing amount is 340g / ㎡; the glued eucalyptus veneers are arranged vertically according to the fiber direction between the layers by hand, and each group contains 9 layers of eucalyptus veneers, and then the slabs are closed for 45 minutes. Until the moisture content of the slab reaches 10%; the slab is sent to the cold press for pre-compression at room temperature: pressure 1.1.5MPa, time 35min, after pre-compression, it is sent to the hot press for hot pressing: the temperature is 115 ° C, the pressure is 1.5 MPa, time 16min; then sanding the thickness of the slab until the deviation of the thickness of the slab does not exceed ±0.2mm; after that, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com