Storage locker

a storage locker and locker technology, applied in special buildings, tents/canopies, building components, etc., can solve the problems of difficult modification of relatively expensive locker construction using framing, etc., and achieve the effect of easy modification, less manufacturing cost, and convenient and inexpensive modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

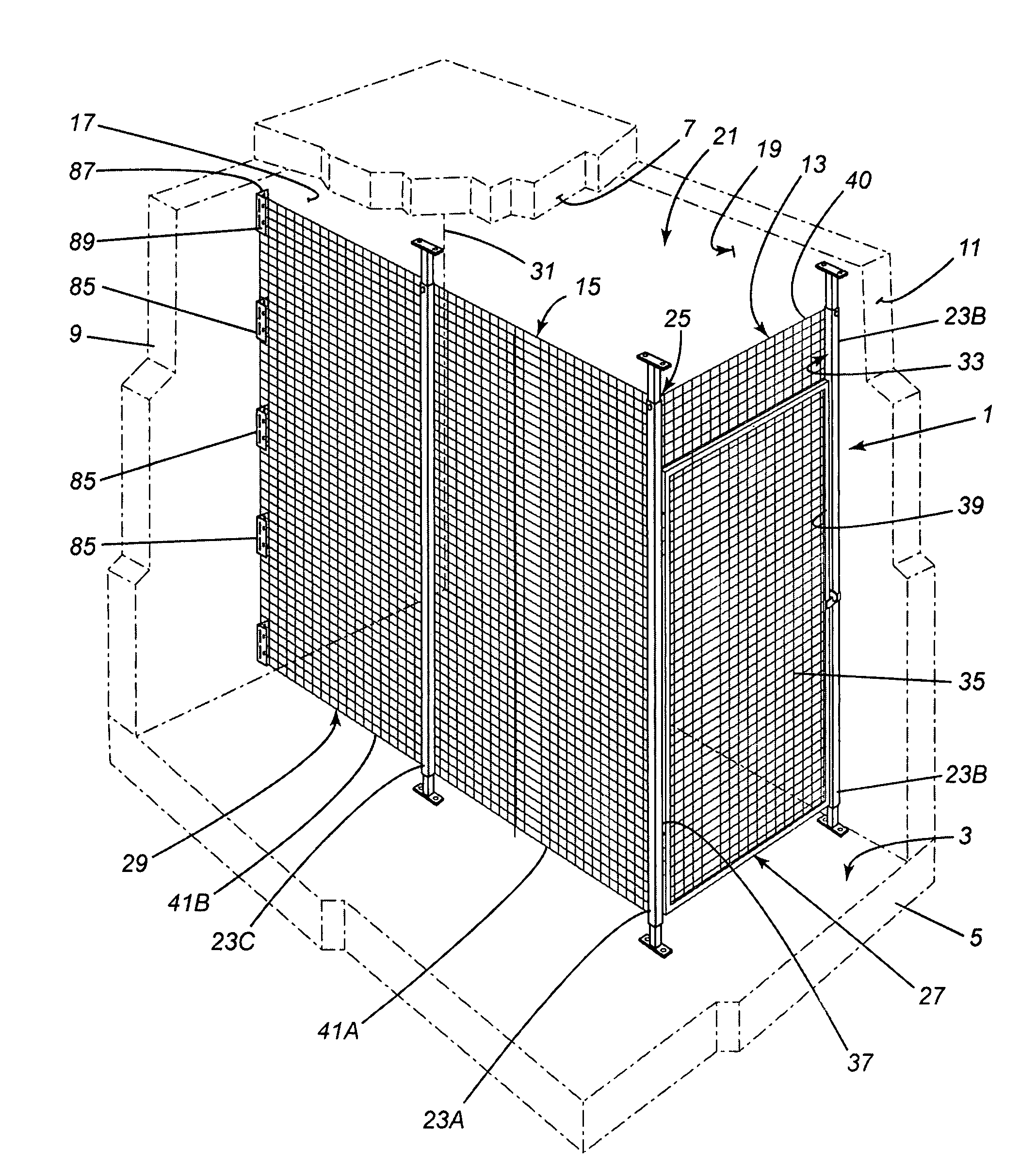

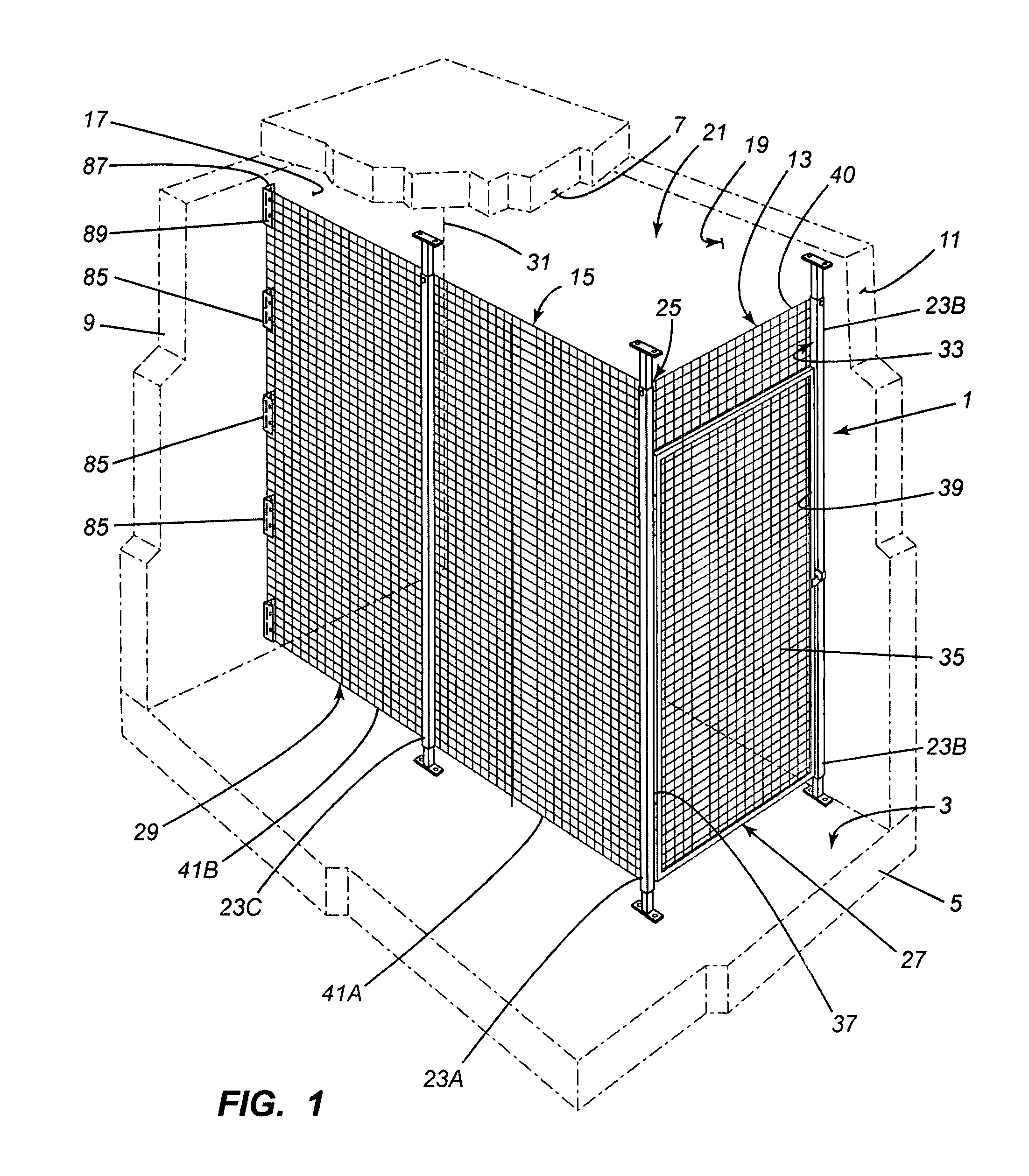

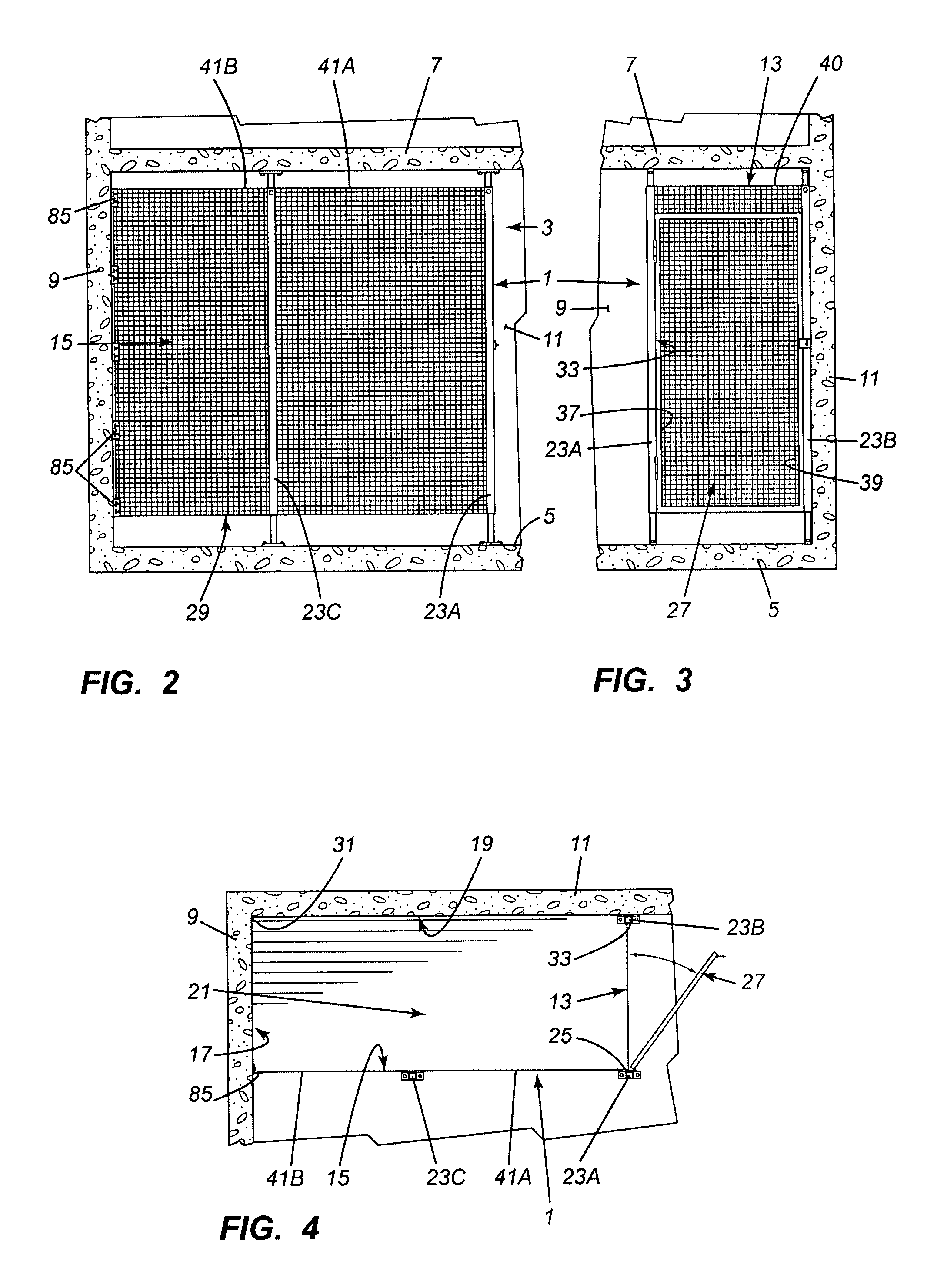

Embodiment Construction

[0032]The locker 1 is adapted to be built in a storage area 3 such as in the basement of an apartment and / or condominium building. As shown in FIGS. 1 to 4, the storage area 3 in the building is defined by a floor 5, a ceiling 7, and walls, two walls 9, 11 of which are shown. The locker has at least four straight walls 13, 15, 17, and 19 joined to define a storage space 21. The floor area of the locker 1 defined by the walls 13, 15, 17 and 19 is usually rectangular but it could have a square or irregular shape as well.

[0033]At least two adjacent walls 13, 15 of the locker 1 have spaced apart posts 23A, 23B, 23C extending between the floor 5 and ceiling 7 of the storage area 3. The posts are identical. The posts are spaced apart a standard distance, such as four feet for example. The posts are preferably adjustable in length as will be described and are fastened to both the floor 5 and ceiling 7. The walls 13, 15 are normally perpendicular to each other and joined at a first corner 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com