Method for producing poly silicate aluminium ferric flocculating agent by utilizing coal gangue

A technology of polyaluminum ferric silicate and coal gangue, applied in aluminum silicate, silicate, flocculation/sedimentation water/sewage treatment, etc. Poor performance, large amount of residual aluminum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

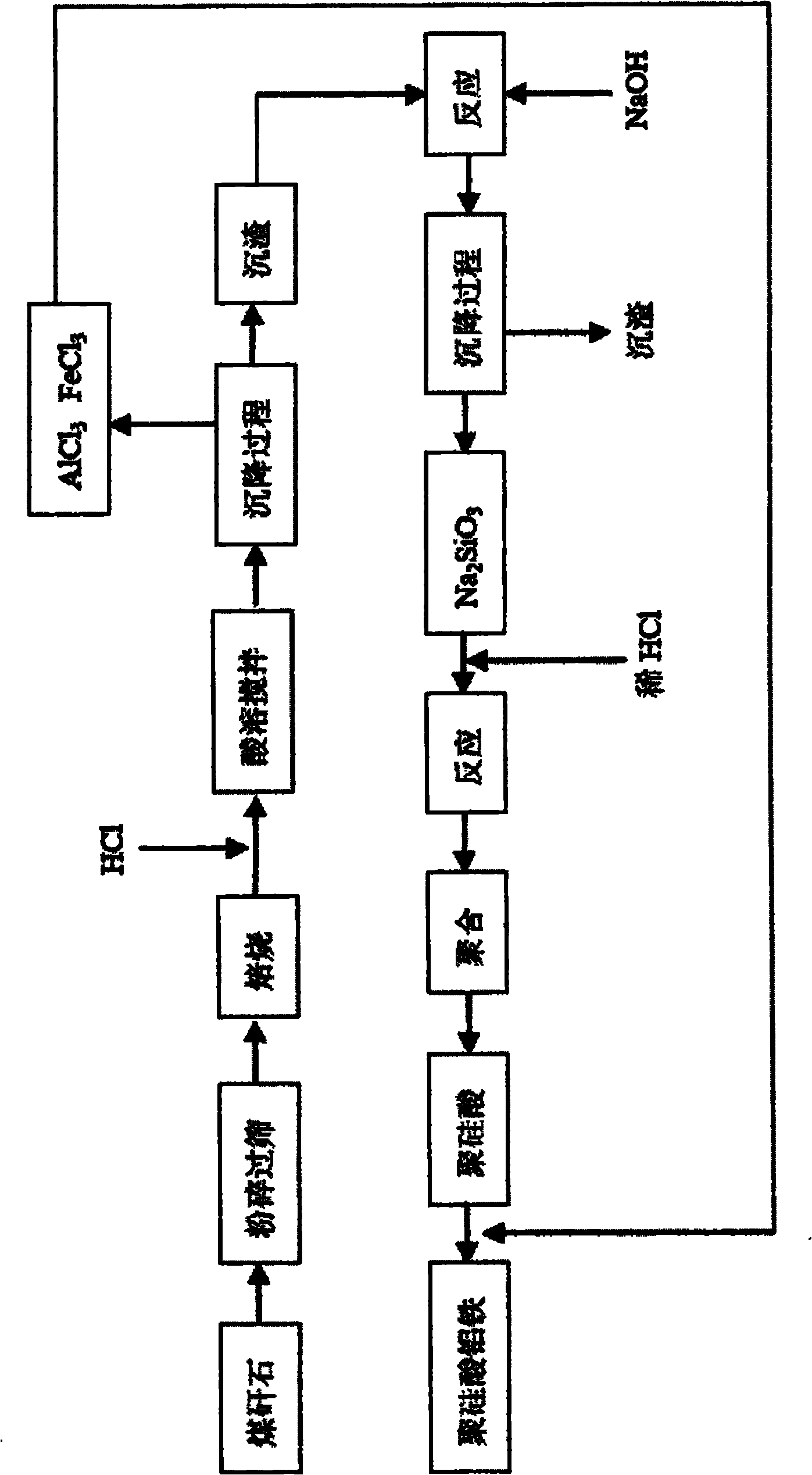

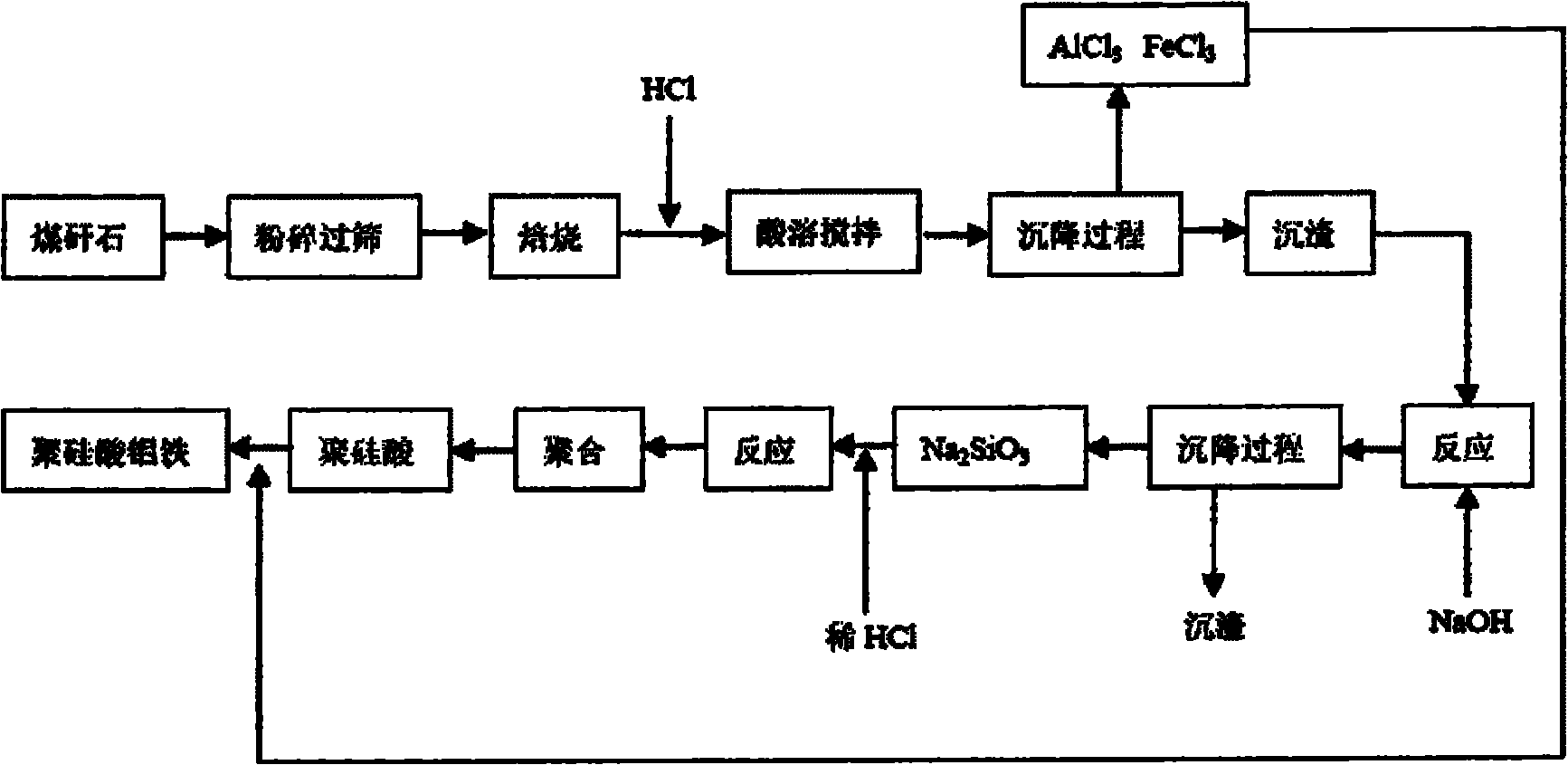

Method used

Image

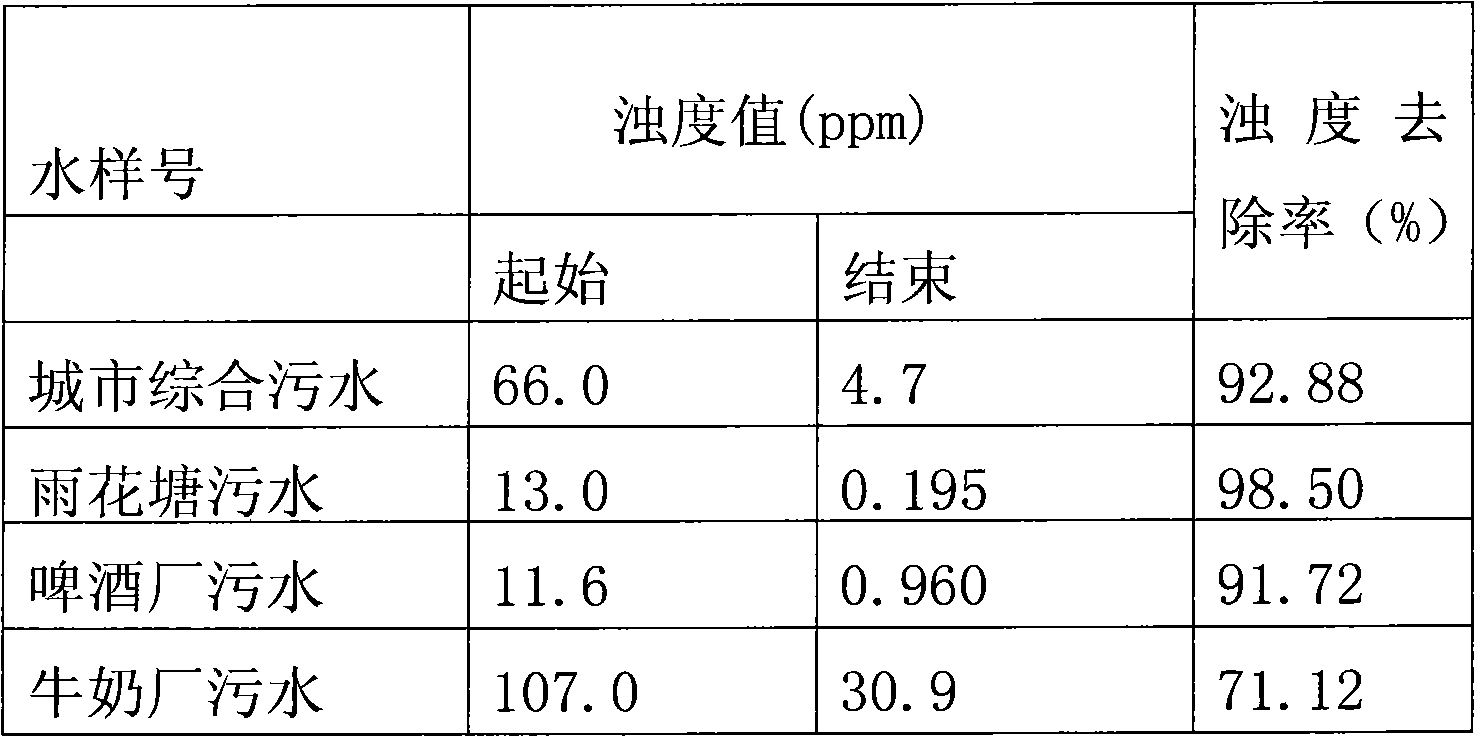

Examples

preparation example Construction

[0020] e. Preparation of polyaluminum-iron silicate solution: the above-prepared polyaluminum-iron solution and activated silicic acid solution are mixed and reacted at a mass ratio of 1:1 to obtain polyaluminum-iron silicate flocculant.

[0021] Adopting the above-mentioned technical scheme, the coal gangue is crushed and roasted at first, which helps to improve the activity of the coal gangue and increase the content of amorphous soluble silica and alumina, thereby increasing the flocculation of the prepared polyaluminosilicate iron iron The adsorption capacity and flocculation effect of the agent; then hydrochloric acid is added to react with the coal gangue after roasting and activation, so that the alumina and iron oxide in the coal gangue react with hydrochloric acid respectively to form a polymerized aluminum-iron solution, and the reacted filter residue is then mixed with Sodium hydroxide is mixed and reacted according to the mass ratio of 2:1-4:1, so that the silicon d...

Embodiment 1

[0034] Crush and sieve 500 kg of coal gangue to a particle size of 80 mesh, put it into a muffle furnace for roasting and activation, the roasting temperature is controlled at 750°C, and the roasting time is 1 hour;

[0035] Mix the roasted coal gangue with 20% hydrochloric acid according to the volume ratio of solid to liquid as 1:4, and heat it in a constant temperature water bath at 80°C at 100r·min -1 Stir at a high speed for 2 hours, filter the reaction solution after the reaction is complete, keep the filtrate and add alkali to adjust the pH value of the solution to 3, and let it stand for 3 hours to obtain the polyaluminium-iron solution;

[0036] After mixing the filter residue and NaOH solid according to the mass ratio of 2:1, react for 5 hours at a pressure of 0.13MPa and a temperature of 120°C. After the reaction is complete, filter the reaction solution, and the filtered filtrate is the sodium silicate solution. ;

[0037] Slowly add sulfuric acid to the sodium si...

Embodiment 2

[0040] Crush 1000 kg of coal gangue to a particle size of 100 mesh, put it into a muffle furnace for roasting and activation, the roasting temperature is controlled at 450°C, and the roasting time is 2 hours;

[0041] Mix the roasted coal gangue with 10% hydrochloric acid according to the solid-liquid volume ratio of 1:5, and heat it in a constant temperature water bath at 90°C at 100r·min -1 Stir at a high speed for 2 hours, filter the reaction solution after the reaction is complete, retain the filtrate and add alkali to adjust the pH value of the solution to 3.2, and let it stand for 4 hours to obtain the polymerized aluminum iron solution;

[0042] After mixing the filter residue and NaOH solid according to the mass ratio of 3:1, react for 6 hours at a pressure of 0.13MPa and a temperature of 110°C. After the reaction is complete, filter the reaction solution, and the filtered filtrate is the sodium silicate solution. ;

[0043] Slowly add sulfuric acid dropwise to the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com