Concrete admixture for PHC pipe pile using superfine molybdenum tailings and pipe pile

A technology of PHC pipe piles and molybdenum tailings, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve environmental pollution problems, achieve low production costs, increase compactness, and solve environmental pollution problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

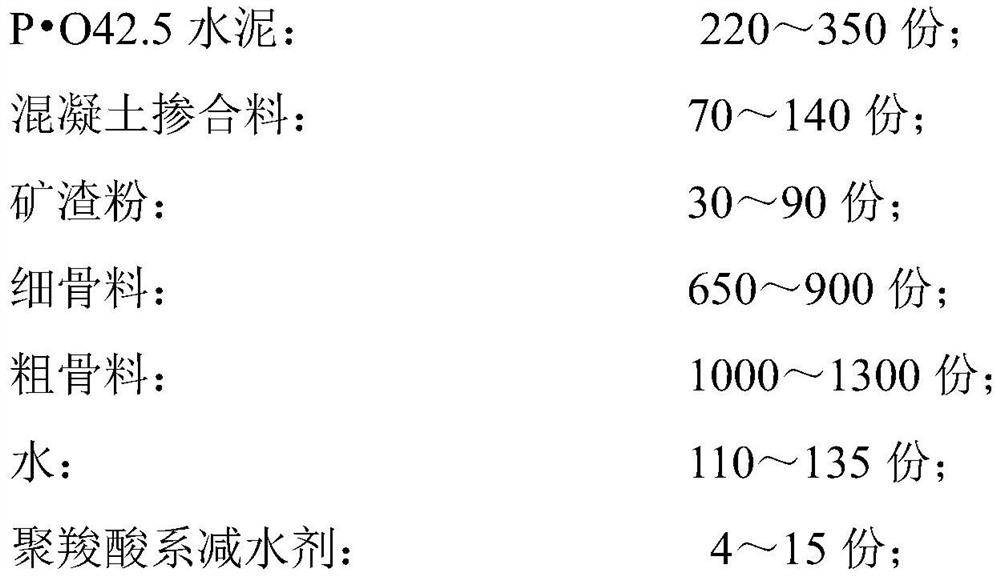

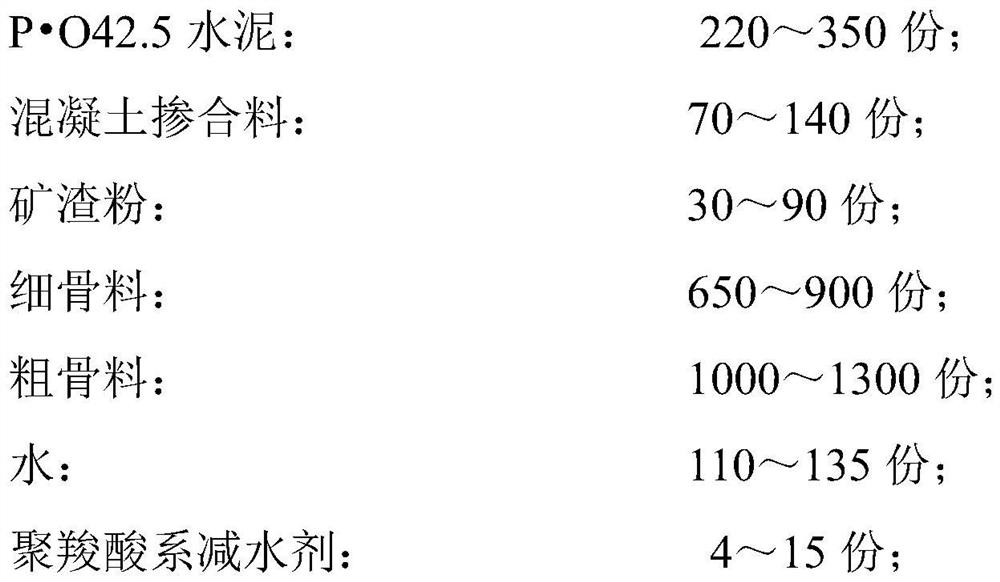

Method used

Image

Examples

Embodiment 1

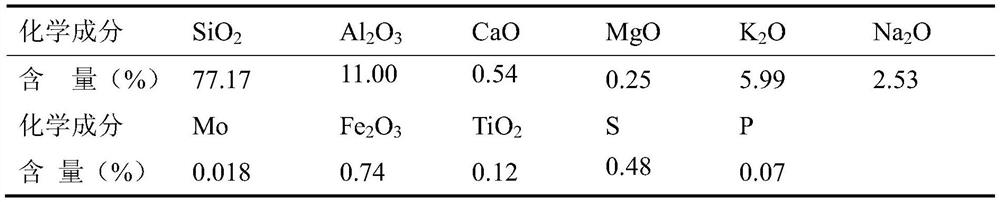

[0037] In this example, molybdenum tailings were taken from Shapinggou molybdenum tailings, and the complete chemical analysis was carried out on the molybdenum tailings. The specific analysis results are shown in Table 1. Among them, the silica content in the molybdenum tailings is 77.17%.

[0038] Table 1 Chemical composition of Shapinggou molybdenum tailings samples

[0039]

[0040] The process of preparing PHC pipe piles is as follows:

[0041] 1) Send the molybdenum tailings in the tailings field to a high-pressure filter press for pressure filtration. The moisture content of the filter cake is 15% to 20%. After being crushed by the crusher, it is sent to the dryer for drying;

[0042] 2) desulfurized gypsum purchased from a thermal power plant, the sulfur trioxide content (mass percentage) in the desulfurized gypsum was tested to be 40.2%, and the desulfurized gypsum was dried with a dryer;

[0043] 3) Send the dried molybdenum tailings and dried desulfurized gypsum ...

Embodiment 2

[0051] In Example 2, molybdenum tailings from a place in Chengde were used as raw materials, and the chemical analysis of the molybdenum tailings was carried out. The analysis results are shown in Table 3. Among them, the silica content in the molybdenum tailings is 74.57%,

[0052] Table 3 Chemical composition of molybdenum tailings samples from a place in Chengde

[0053]

[0054] The process of preparing PHC pipe piles is as follows:

[0055] 1) Send the molybdenum tailings in the tailings field to a high-pressure filter press for pressure filtration. The moisture content of the filter cake is 13% to 16%. After being crushed by the crusher, it is sent to the dryer for drying;

[0056] 2) desulfurized gypsum purchased from a thermal power plant, the sulfur trioxide content (mass percentage) in the desulfurized gypsum was tested to be 38.5%, and the desulfurized gypsum was dried with a dryer;

[0057] 3) Send the dried molybdenum tailings and dried desulfurized gypsum in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com