Automatic separator of coal gangue

An automatic sorting and coal gangue technology, applied in sorting, conveyor objects, transportation and packaging, etc., can solve problems such as poor sorting effect and inaccurate measurement of dual-energy gamma ray sources, and achieve good results, Measuring Accurate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

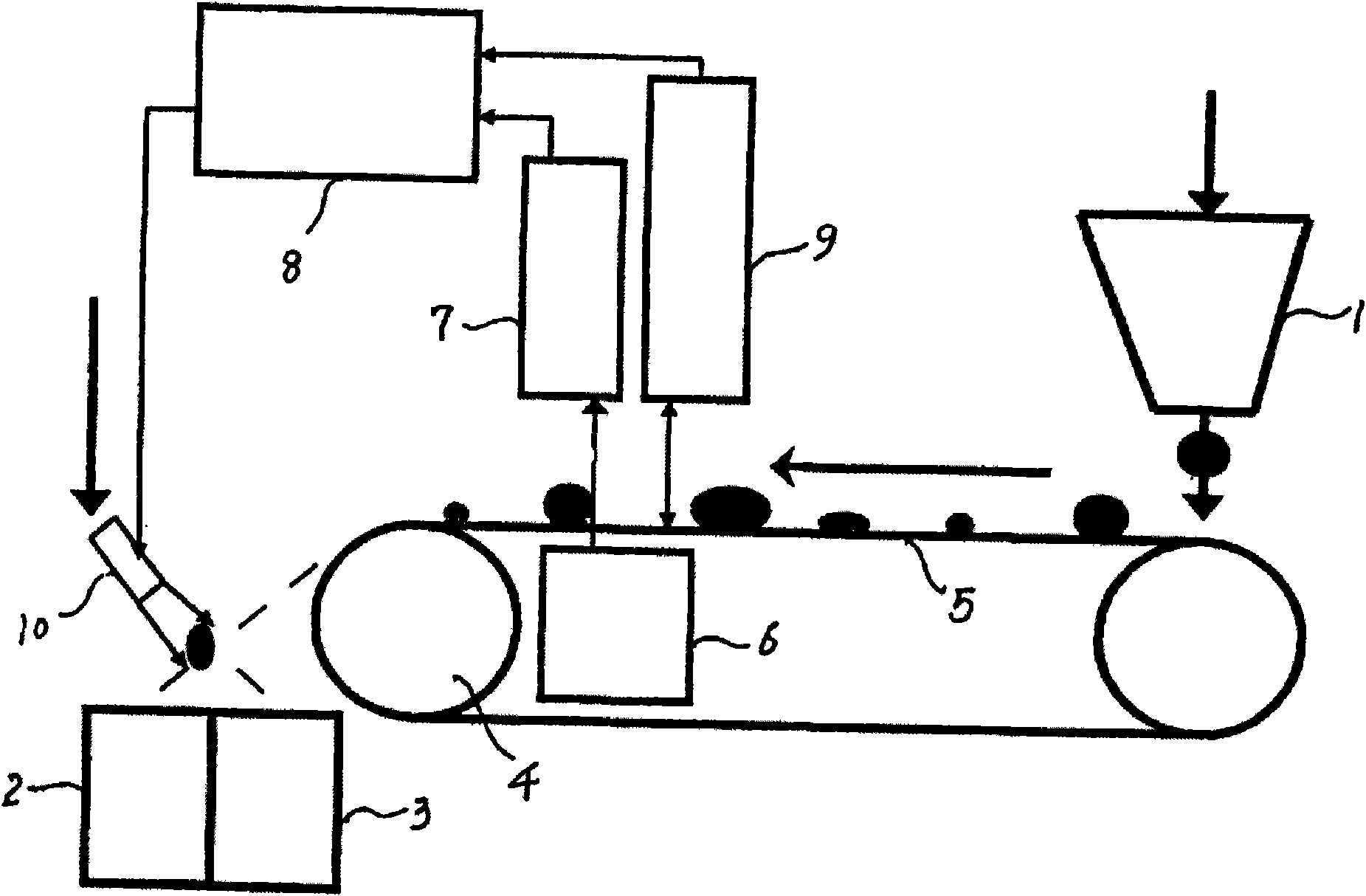

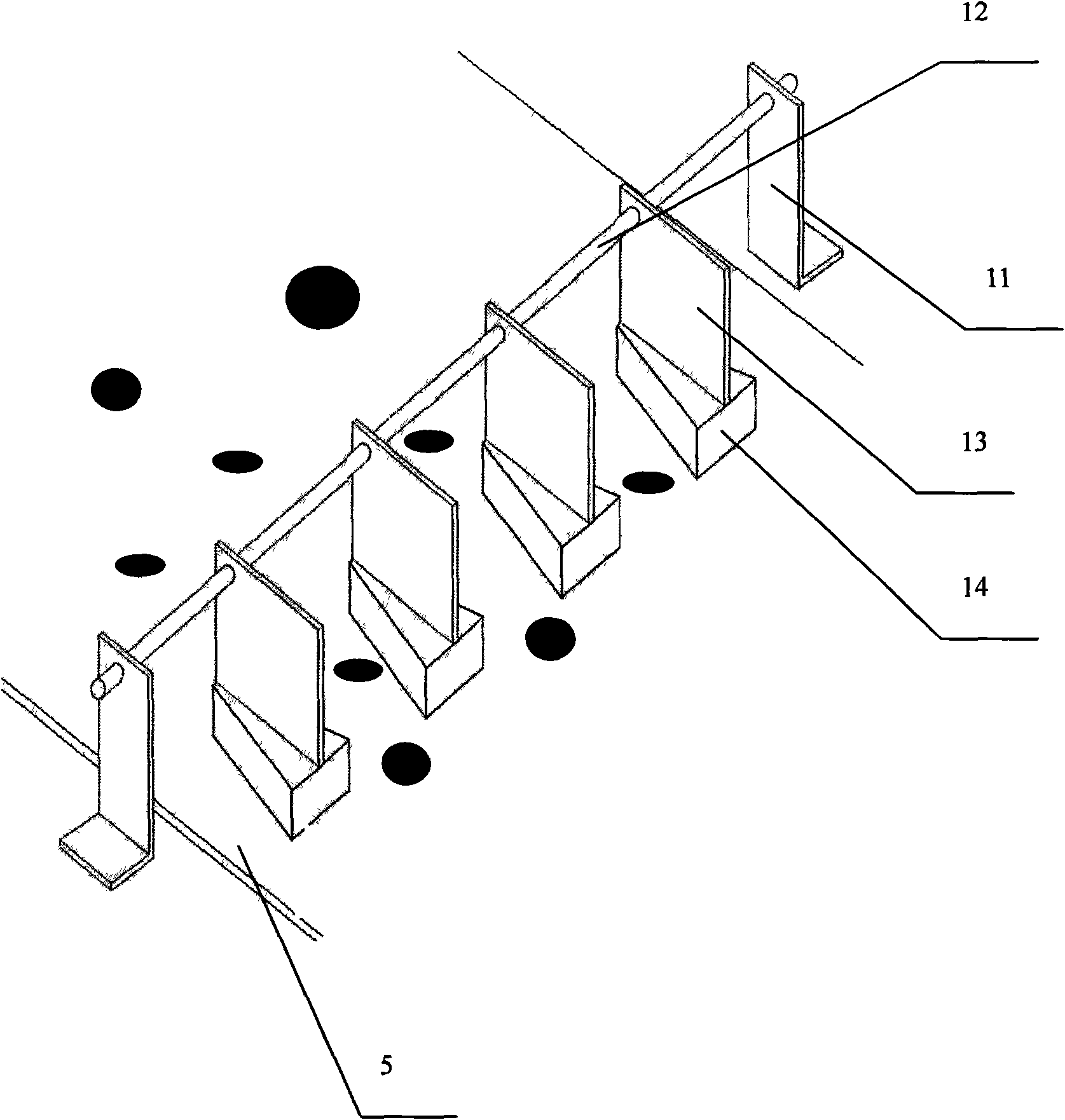

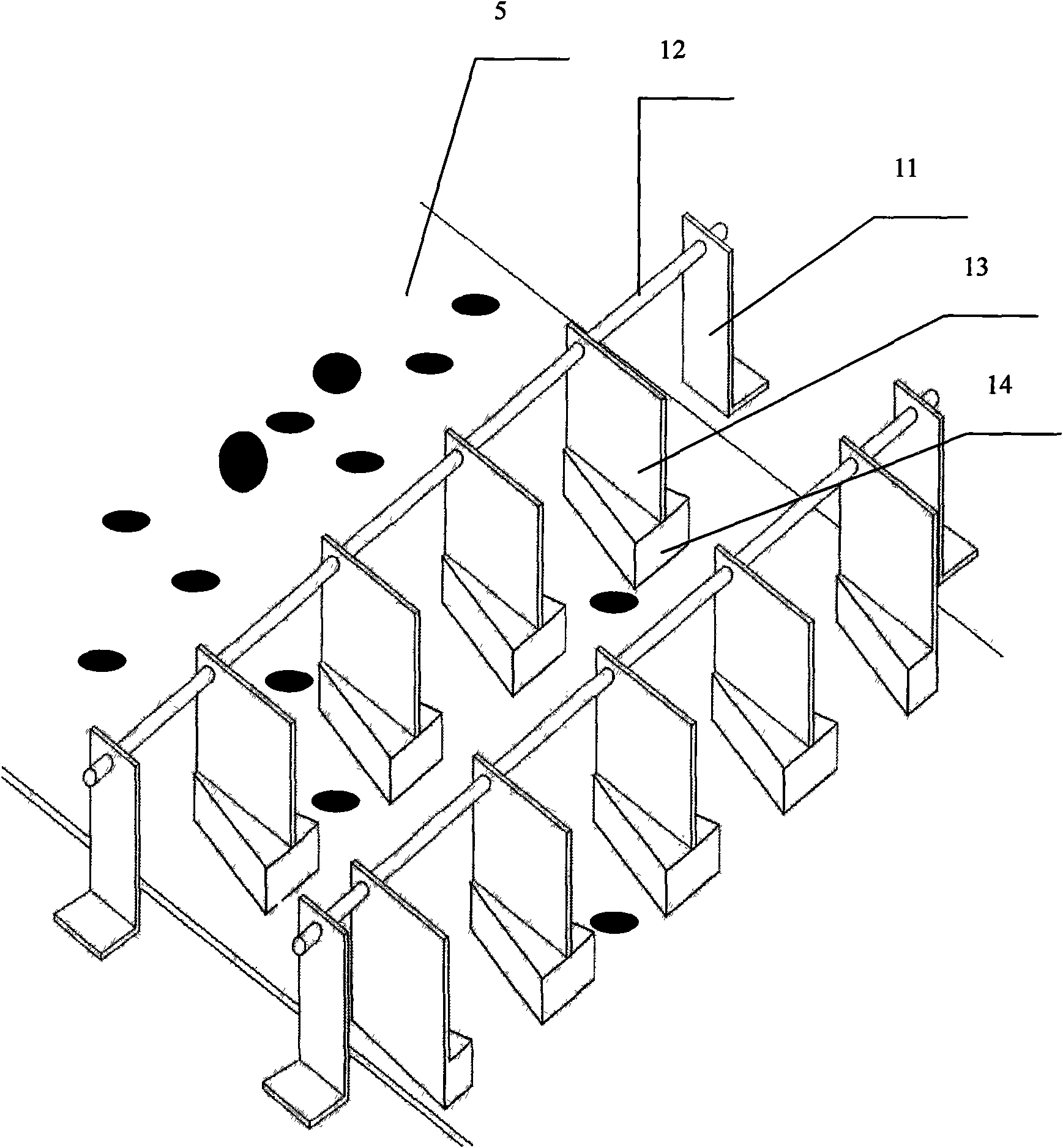

[0023] like figure 1 As shown, a coal gangue automatic sorting machine includes a raw material feeding hopper 1, a coal receiving hopper 2, and a gangue receiving hopper 3, which is arranged between the raw material feeding hopper 1 and the coal and gangue receiving hoppers 2 and 3 The conveyor belt conveyor 4, the identification and sorting control mechanism, the executive mechanism and the queuing mechanism arranged on the conveyor belt, the identification and sorting control mechanism include a single-energy gamma ray source 6 arranged under the conveyor belt 5, located at the conveyor belt 5 The top corresponds to the ray sensor 7 at the position of the single-energy gamma ray source 6, the measurement and control instrument 8 electrically connected to the ray sensor 7, and the ultrasonic transmitting receiver 9 electrically connected to the measurement and control instrument 8 positioned above the conveyor belt 5; The transmitter receiver 9 can be arranged between the ray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com