Iron improvement and silicon reduction beneficiation method of high ferrosilite and lean magnet iron ore

A technology of magnetite ore and beneficiation method, applied in chemical instruments and methods, magnetic separation, wet separation, etc., can solve the problems of large area of dressing plant, failure to achieve the principle of energy saving, etc., to improve iron grade and reduce dust The effect of large pollution and treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

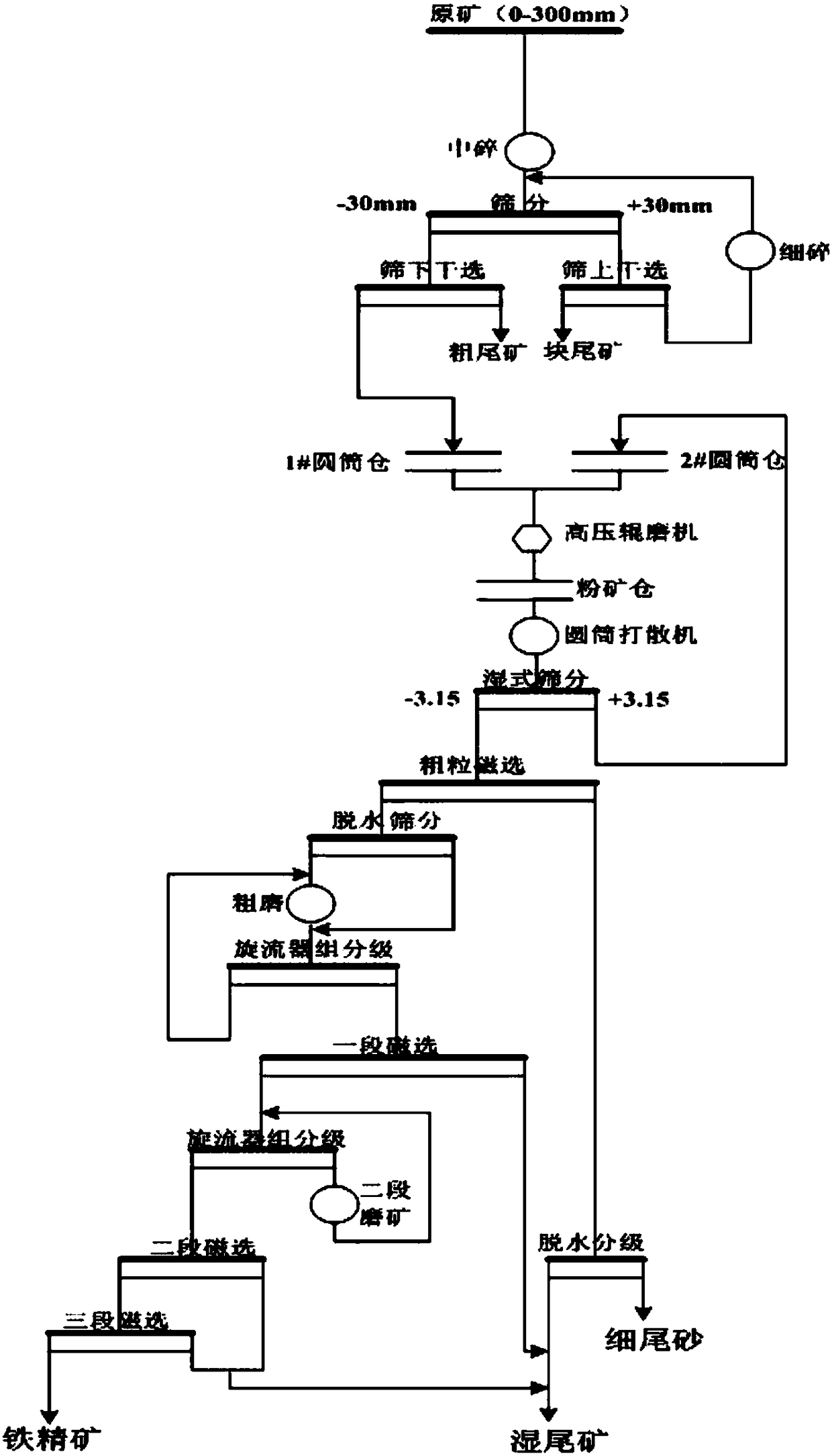

[0028] In order to describe the present invention, a method for increasing iron and reducing silicon ore of high silicate iron-poor magnetite ore of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0029] A method for iron-increasing and silicon-decreasing beneficiation of high-silicate iron-poor magnetite ore of the present invention has been practically applied in Zhangzhuang Mining Co., Ltd. of Anhui Masteel.

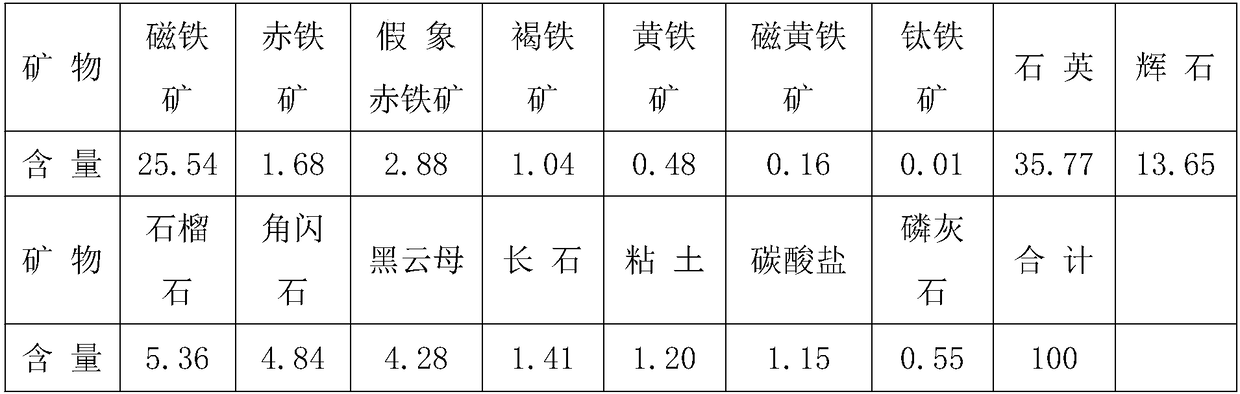

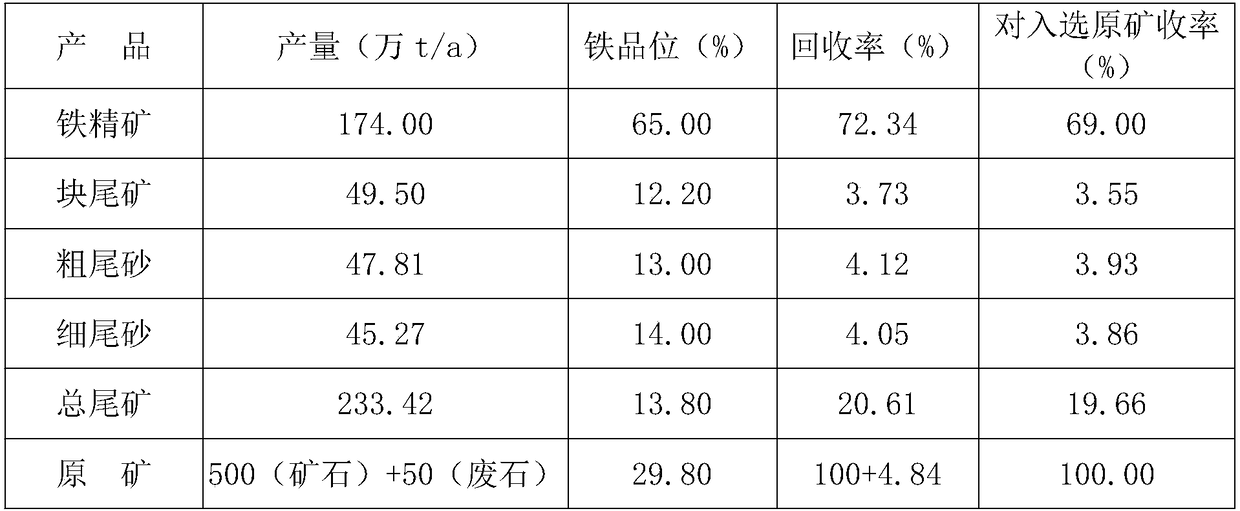

[0030] The mine adopts underground mining, which adopts ore-rock mixed extraction. If the annual output of iron ore is 5 million tons, the mining grade is 31.27%, and the mining block degree is 800-0mm; at the same time, the surrounding rock is mixed with 500,000 tons, and the surrounding rock grade is 15.14%. . The coarse crushing equipment adopts jaw crusher, which is installed underground. After coarse crushing, the raw ore has a particle size of 300-0mm. The effective volume of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com