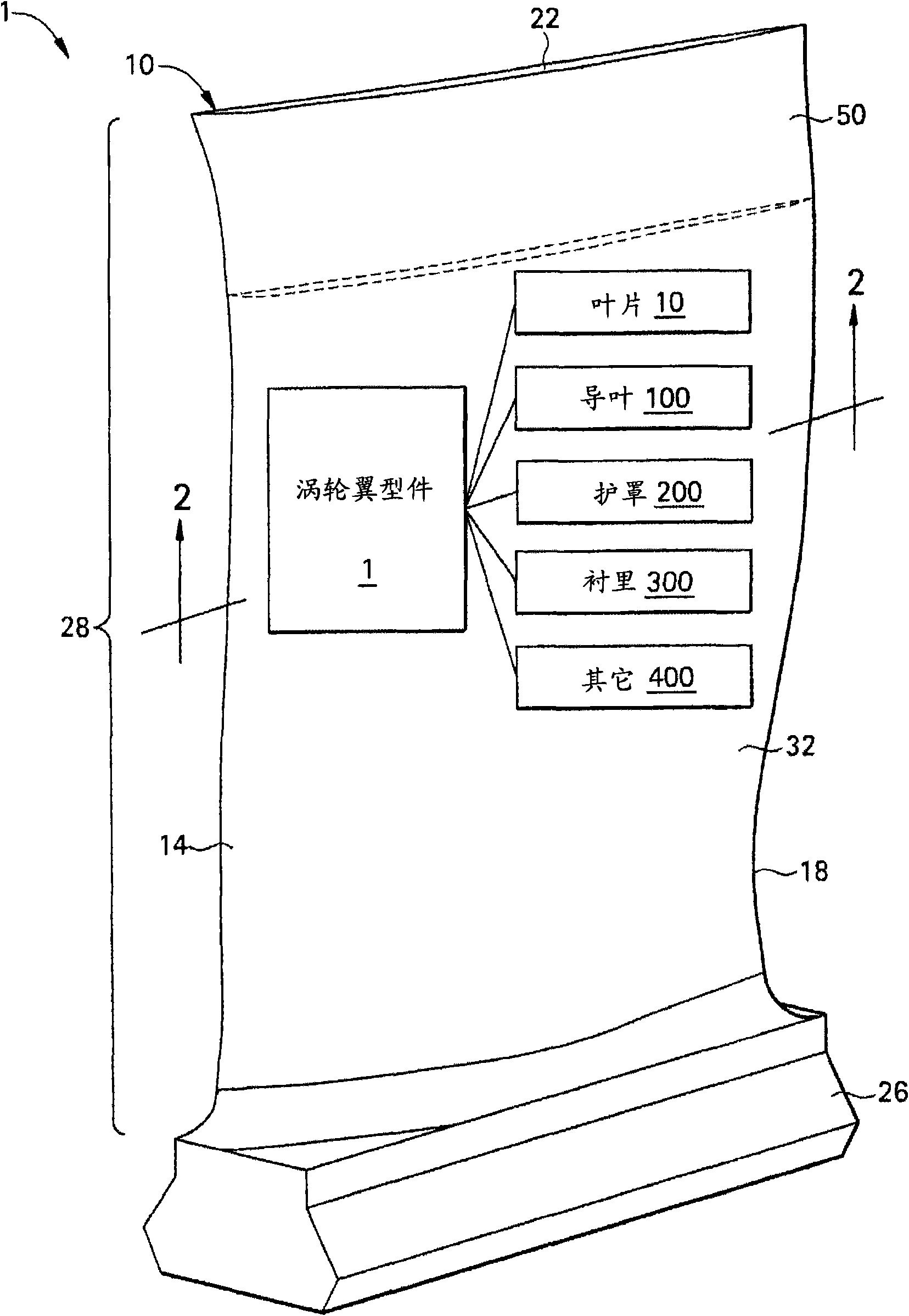

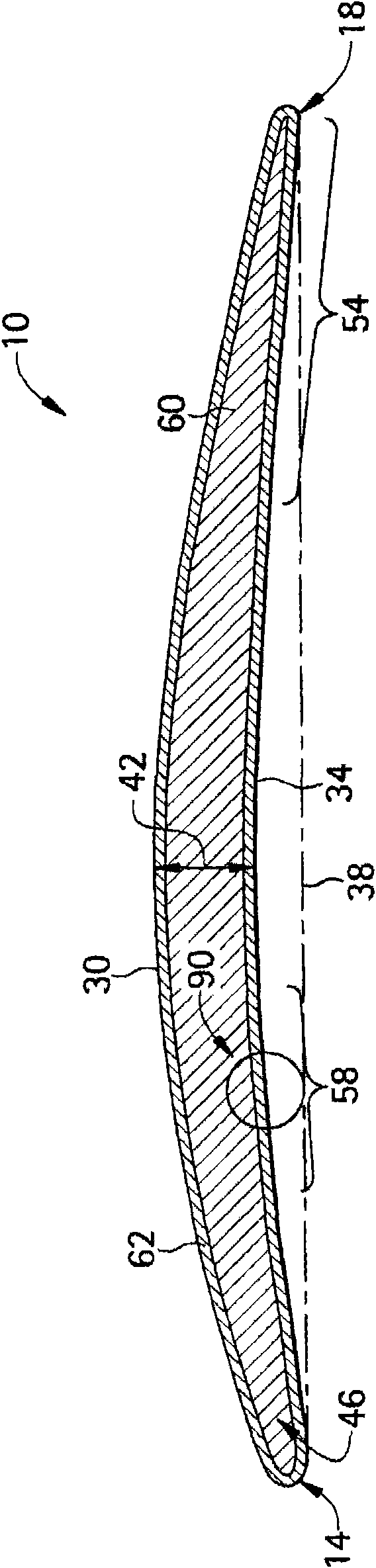

Erosion and corrosion resistant turbine compressor airfoil and method of making the same

A technology of turbo compressors, airfoils, applied in the direction of components, pump elements, mechanical equipment, etc. of pumping devices for elastic fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

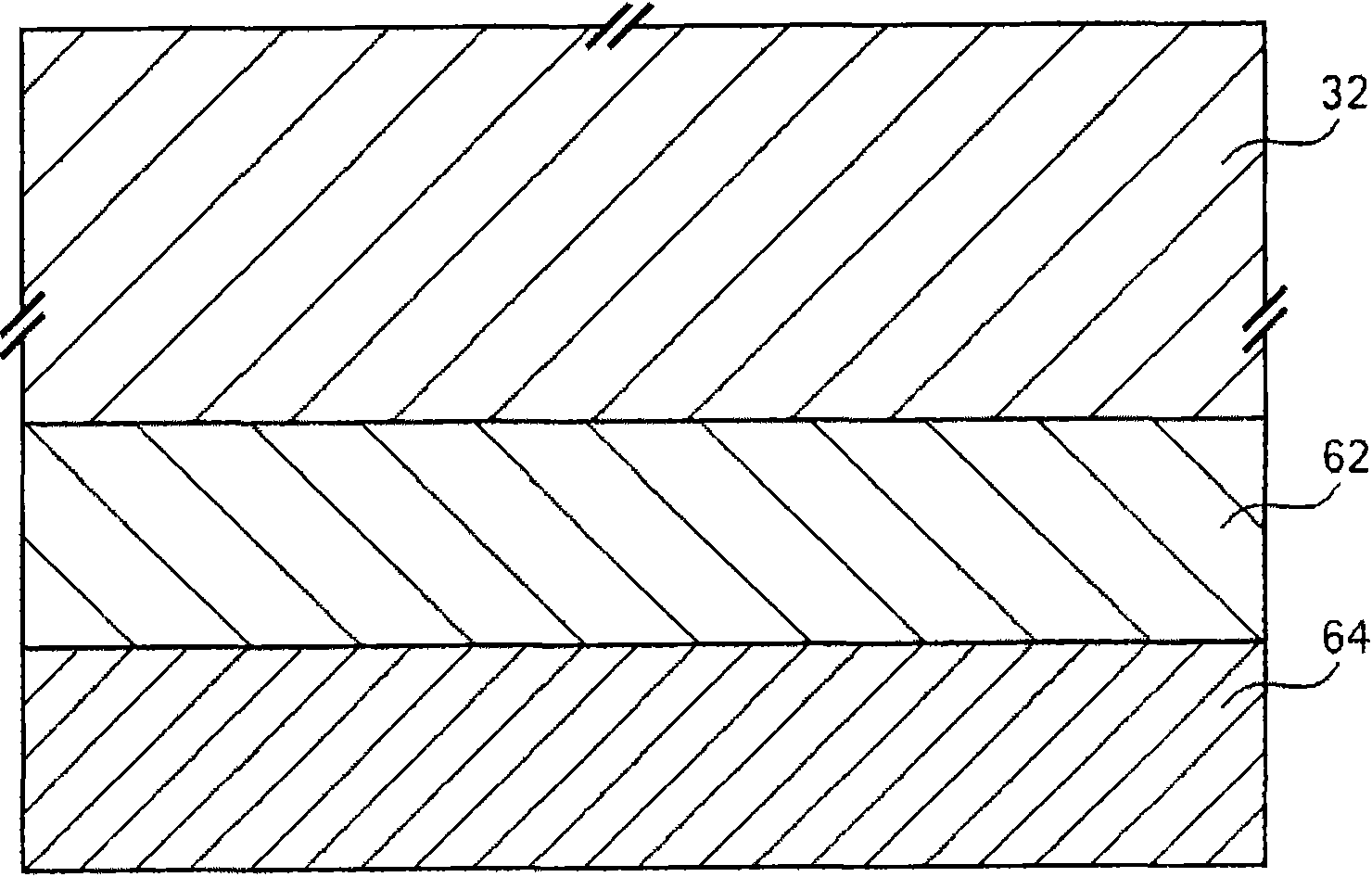

[0072] A water drop erosion test is used to simulate water impact on compressor components in a turbine during water washout and water jet power increase. Control particle velocity and droplet size to best reproduce the turbo environment. A series of cylindrical test specimens of Custom 450 stainless steel were coated with several corrosion-resistant coatings including a single layer of TiN with a thickness of approximately 6 to 8 microns, multiple layers of Ti and TiN each with a thickness of 5 microns. minimum thickness and have a total thickness of about 45 microns, and a WC-CoCr layer having a composition by weight of 10% Co, 4% Cr and balance WC and a thickness of about 4-6 mils. Test coupons with these erosion-resistant coatings were subjected to testing in a rotating test fixture, where the test coupons were attached to the outboard end of the leading edge of a motor-driven five-root blade. The apparatus was designed to rotate the blade and test specimen at 800 feet pe...

example 2

[0074] In a second test, polarization sweep and galvanic corrosion tests were performed on Custom 450 test coupons coated with the airfoil coating described herein. A series of Custom 450 stainless steel test specimens were coated with an airfoil coating, which consisted of a sheet of Custom 450 as the airfoil surface, a 50-micron thick Al coating deposited by an air plasma spray (APS) process, and an 150 μm thick WC-CoCr coating deposited by fuel (HVOF) spraying process. Test conditions included 5% NaCl (similar to salt spray chloride levels), which is acidic, pH = 4.0 at 50 degrees Celsius, to simulate condensing gas with moisture and salt. The test is an accelerated corrosion test used to evaluate coating performance. Cyclic Polarization Corrosion Testing was utilized according to ASTM G61 for the creviced Custom 450 coupons. The test specimens were gapped using ceramic washers torqued down to 40 foot-pounds by the associated bolts. Such as Figure 9 As shown, hysteresi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com