Blocky bionic material, method for manufacturing same and application of blocky bionic material

A biomimetic material and block technology, applied in the field of biomimetic materials, can solve the problems of complex preparation procedures, narrow application range, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a block bionic material, comprising:

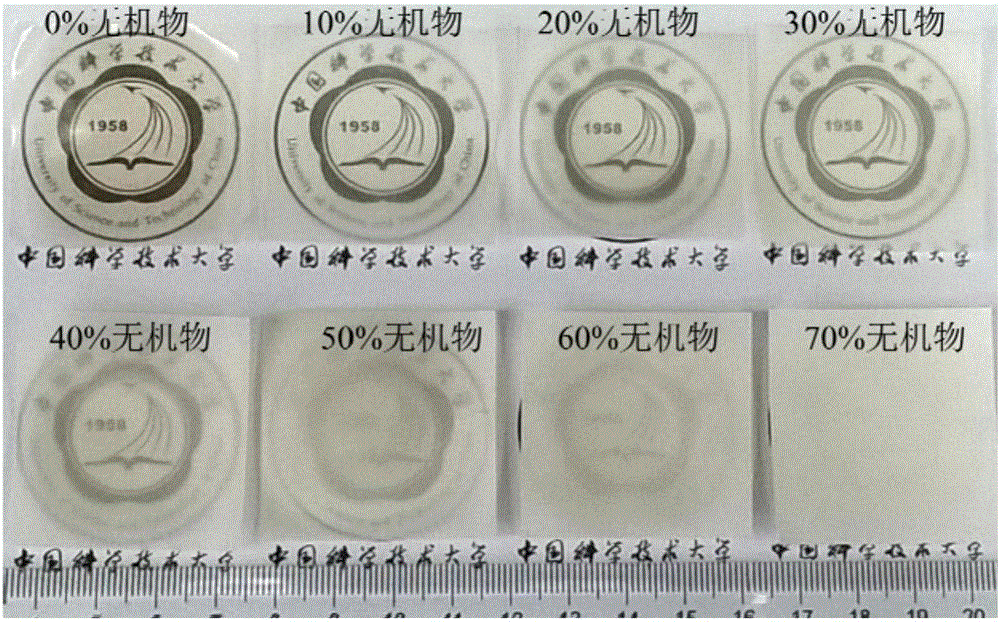

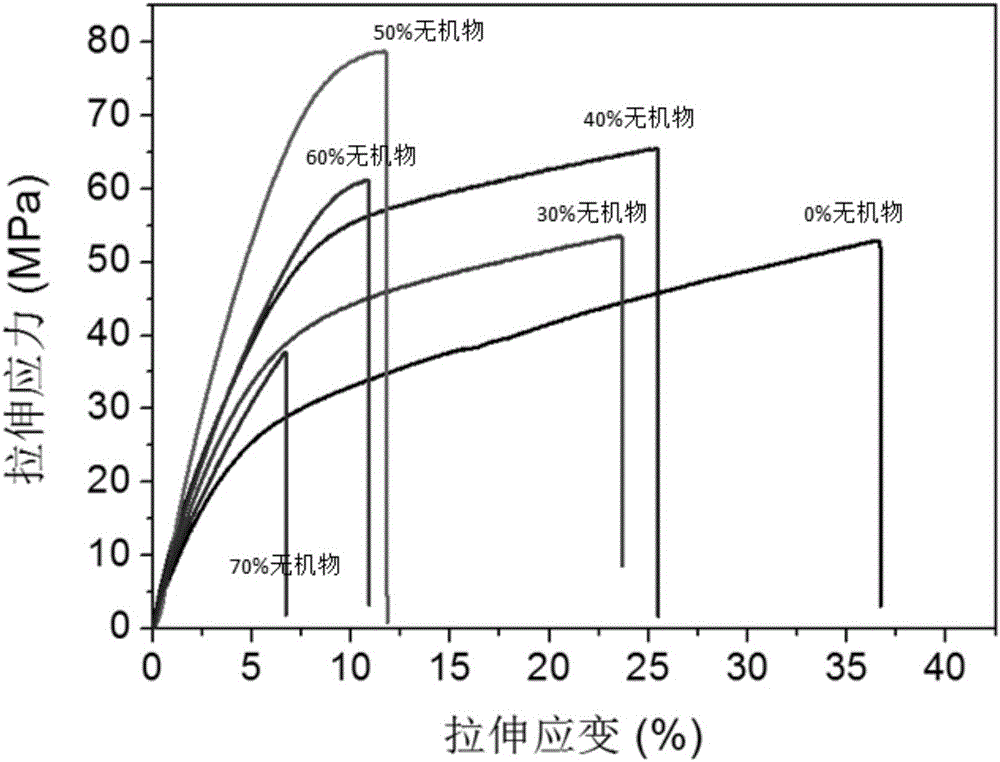

[0025] The inorganic material is mixed with the first polymer to form a film to obtain a biomimetic structure film;

[0026] 2) placing the second polymer between adjacent biomimetic structure films and compounding to obtain a block biomimetic material;

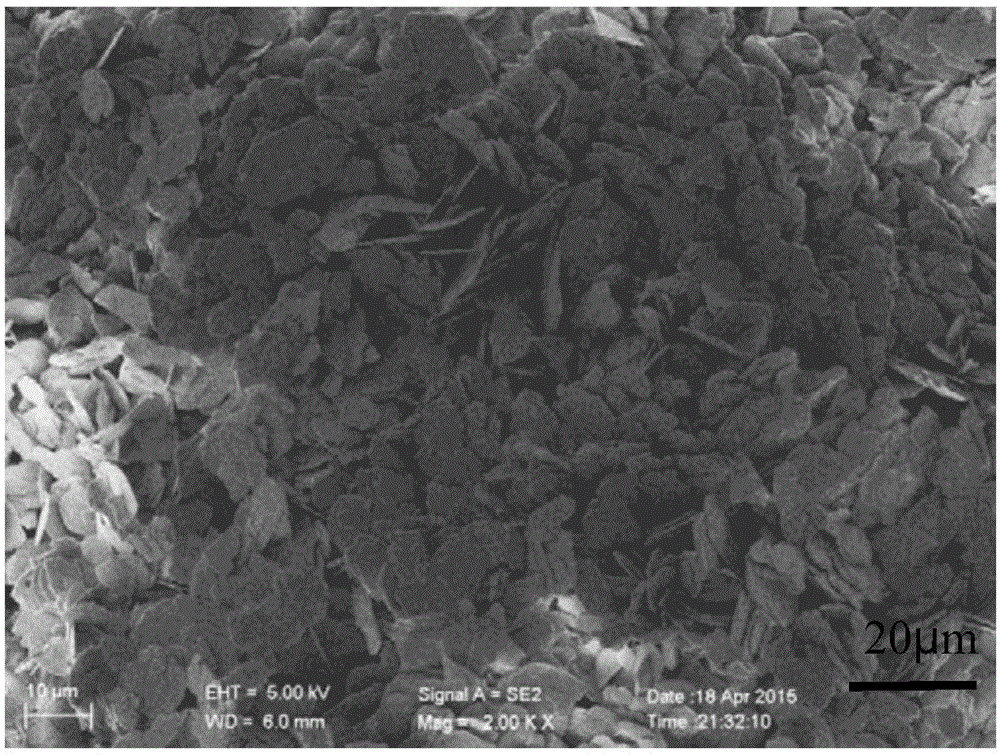

[0027] According to the present invention, the inorganic material is mixed with the first polymer to form a film to obtain a bionic structure film; the inorganic material is natural clay attapulgite, montmorillonite nanosheet, natural mineral mica microsheet, alumina microsheet, silicon Calcium acid nanowires, calcium phosphate nanowires, calcium carbonate microsheets, brushite microsheets, graphene oxide sheets or carbon nanotubes; more preferably natural clay, montmorillonite nanosheets, natural mineral mica nanosheets, oxidized Aluminum microflakes, calcium silicate nanowires, calcium phosphate nanowires, brushite microflakes, grap...

Embodiment 1

[0042] Preparation of brushite-sodium alginate-chitosan three-dimensional bulk biomimetic material:

[0043] Preparation of sodium alginate solution and chitosan solution: Weigh 5.0g sodium alginate powder in a 250ml beaker, and measure 250ml deionized water in the beaker, use mechanical stirring, 300rpm, 12h, finally obtain a uniform 2% ( 20mg / ml) of sodium alginate solution, placed in the refrigerator freezer for use. Weigh 0.5g of chitosan powder in a 100ml beaker, and measure 50ml of deionized water in the beaker, use mechanical stirring, 300rpm, slowly add 0.5ml of acetic acid in the mixing system, stir for 6h, and finally obtain a uniform 1 % (10mg / ml) chitosan solution, placed in the refrigerator freezer stand-by.

[0044] Preparation of brushite micro-sheets: Weigh 6.062g of anhydrous calcium chloride into a 500ml beaker, measure 400ml of deionized water into the beaker, stir and dissolve to obtain a clear calcium chloride solution. Weigh 1.65 g of potassium dihydrog...

Embodiment 2

[0060] Preparation of brushite-sodium alginate-polydopamine three-dimensional bulk biomimetic material:

[0061] The preparation of sodium alginate solution and brushite microsheets is the same as in Example 1.

[0062] Preparation of dopamine solution: Weigh 1g of dopamine hydrochloride in a 100ml beaker, and measure 50ml of phosphate buffered saline water in the beaker, use mechanical stirring to dissolve at 0°C to obtain a uniform 1% (10mg / ml) dopamine hydrochloride solution , placed in the freezer for later use.

[0063] The preparation of the brushite-sodium alginate biomimetic structure film is the same as in Example 1.

[0064] Preparation of brushite-sodium alginate-polydopamine three-dimensional block biomimetic material: Spray a layer of 1% dopamine hydrochloride solution on the surface of the prepared biomimetic structure film. Lay another layer on it and continue spraying, and repeat multiple layers to finally obtain a block to be pressed with multi-layer biomime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass volume concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Mass volume concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com