Self-Repairing, Reinforced Matrix Materials

a reinforced matrix and self-repairing technology, applied in the field of matrix materials, can solve the problems of low tensile strength, low impact resistance of concrete, frequent brittleness, etc., and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

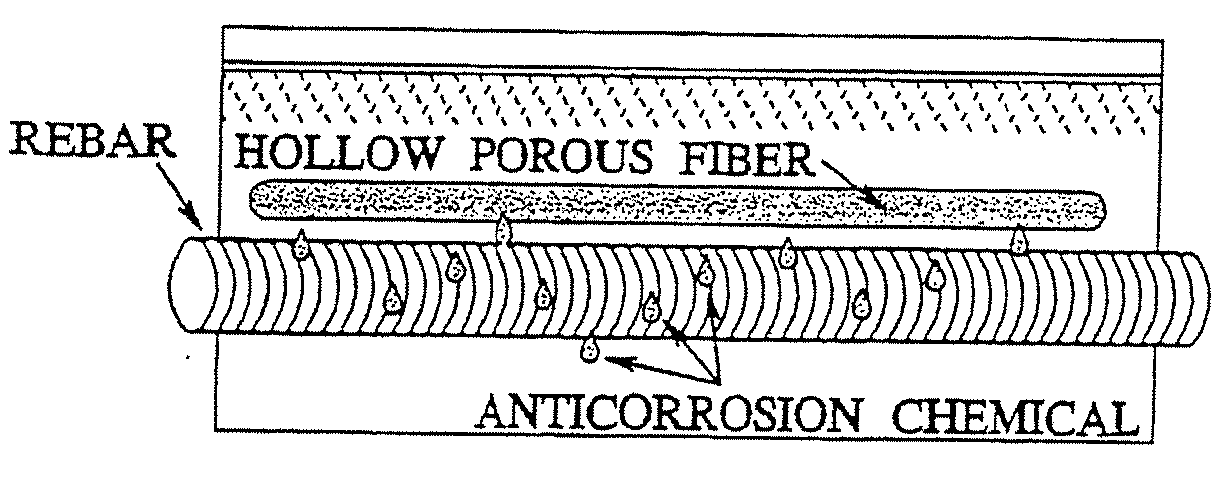

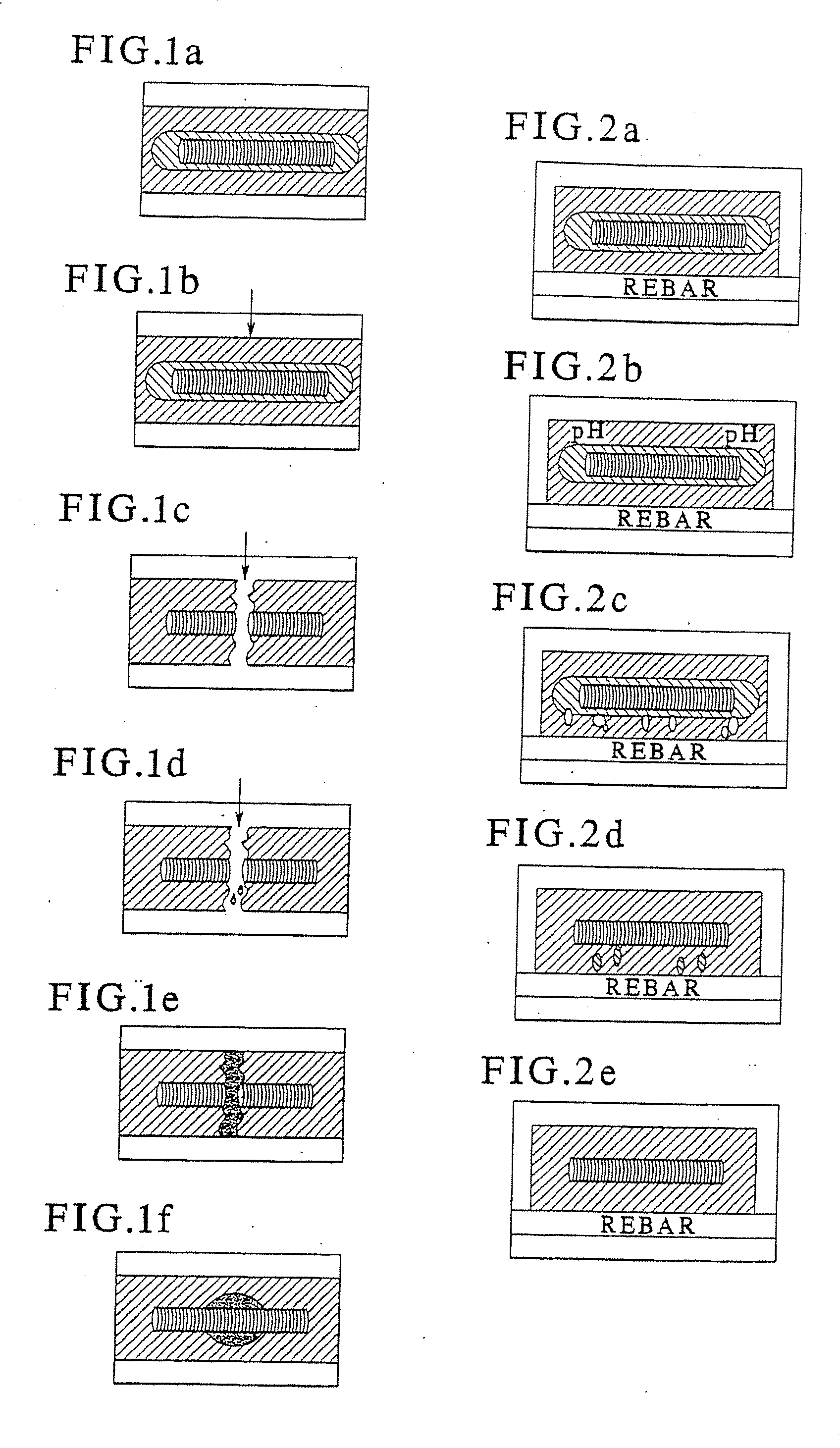

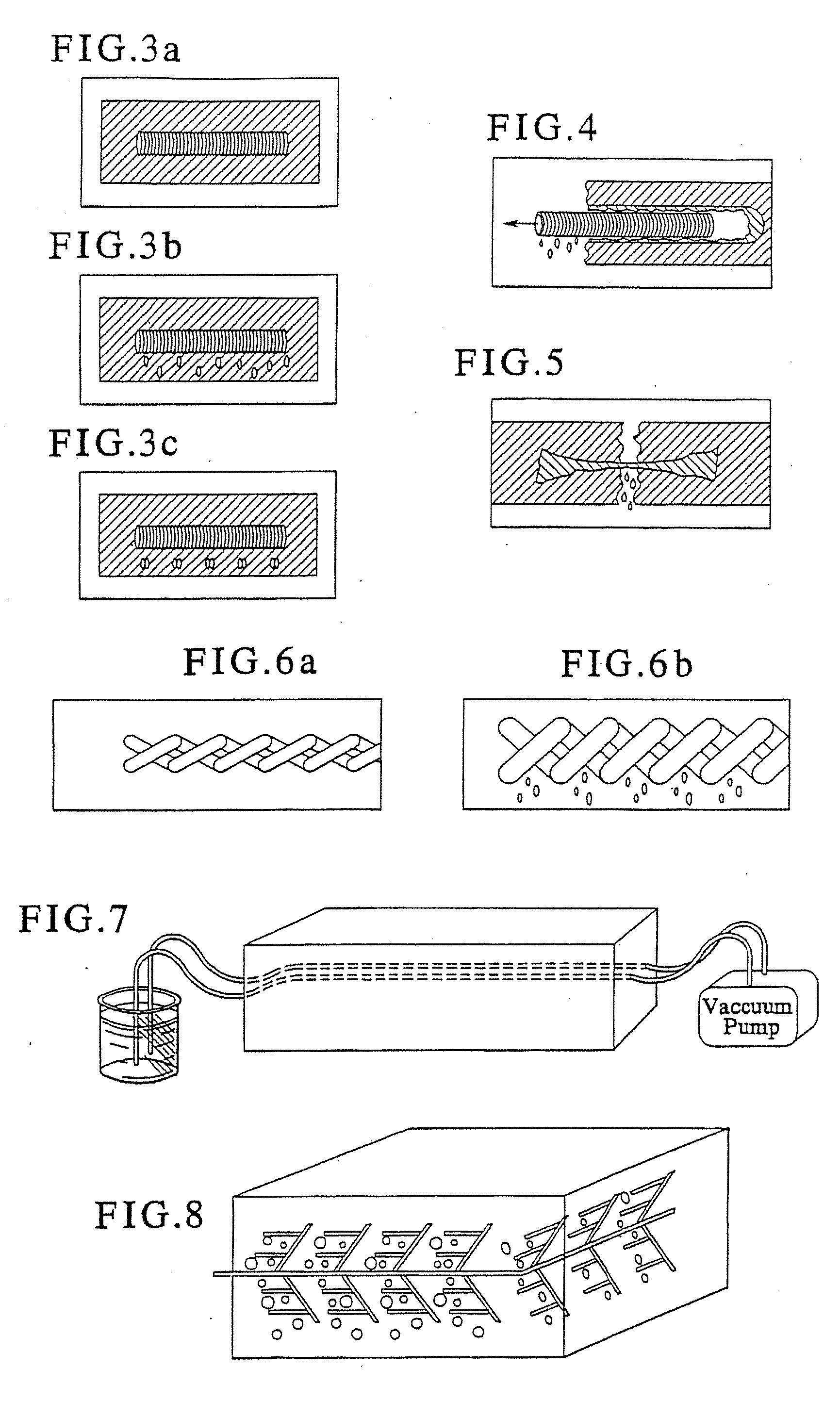

[0061] In accordance with the present invention, new and improved shaped articles comprise curable, settable, cross-linkable and / or hardenable matrix materials. The matrix material comprises a continuous phase and is a material that may be shaped to form a three-dimensional shaped article adapted for a particular use. Matrix materials can include any curable, settable or hardenable materials used in construction, building, roofing, roadway, aircraft, automotive, marine, appliances, transportation and / or biomedical fields for making shaped articles. Typically these materials will be moldable or castable to form shaped objects or may be laminated or assembled into finished products. The matrix materials may be inorganic or organic in nature and may include by way of illustration: cement, concrete, sintered fly ash or bottom ash / phosphoric acid mixtures, ceramic including, for example, silicon oxide, titanium oxide, silicon nitride, and metals such as aluminum, steel or other metal all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

| magnetostrictive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com