Formaldehyde-removing and air-purifying filter core based on inclined-hole aluminum honeycomb plate and preparation method thereof

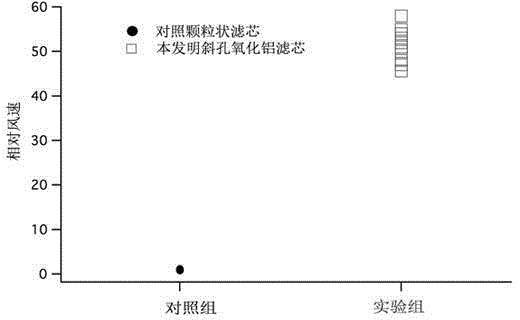

An air purification and aluminum honeycomb technology, applied in the field of preparation and design of formaldehyde-removing air purification filter elements, can solve problems such as affecting normal use, air duct blockage, and low wind power, and achieve the effects of thorough removal, increased contact time, and small wind resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

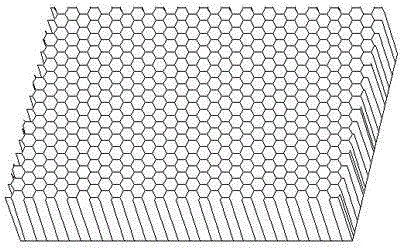

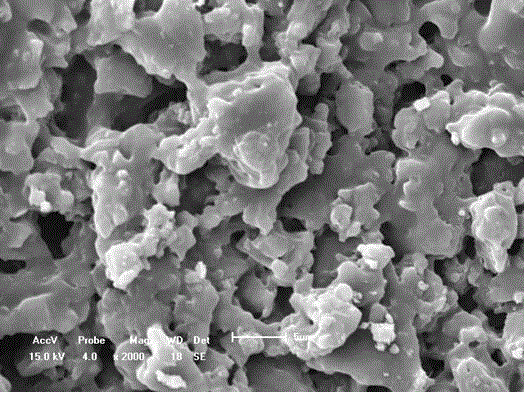

[0027] In all the embodiments, the aluminum honeycomb panels used in the formaldehyde-removing air purification filter element based on the inclined-hole aluminum honeycomb panels all adopt aluminum substrates with a length and width of 30 cm to 20 cm, and the thickness of the aluminum honeycomb panels is 0.5-1.5 cm. The aluminum substrate is a plate-shaped body composed of hexagonal channels, and the angle between the hexagonal channels and the vertical direction of the front of the plate-shaped body is 5-20 degrees. The components of the formaldehyde removal coating include activated carbon, calcium peroxide, calcium oxide, manganese dioxide, potassium carbonate, and adhesive. The formaldehyde removal coating is coated on the inner surface of the hexagonal channel of the aluminum honeycomb panel and cured to form a formaldehyde removal layer.

[0028] Place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com