Preparation method of aluminum honeycomb core materials and honey comb plates

A technology of aluminum honeycomb and honeycomb panels, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of easy degumming of panels and low mechanical properties, and achieve the effects of good stability, high strength and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

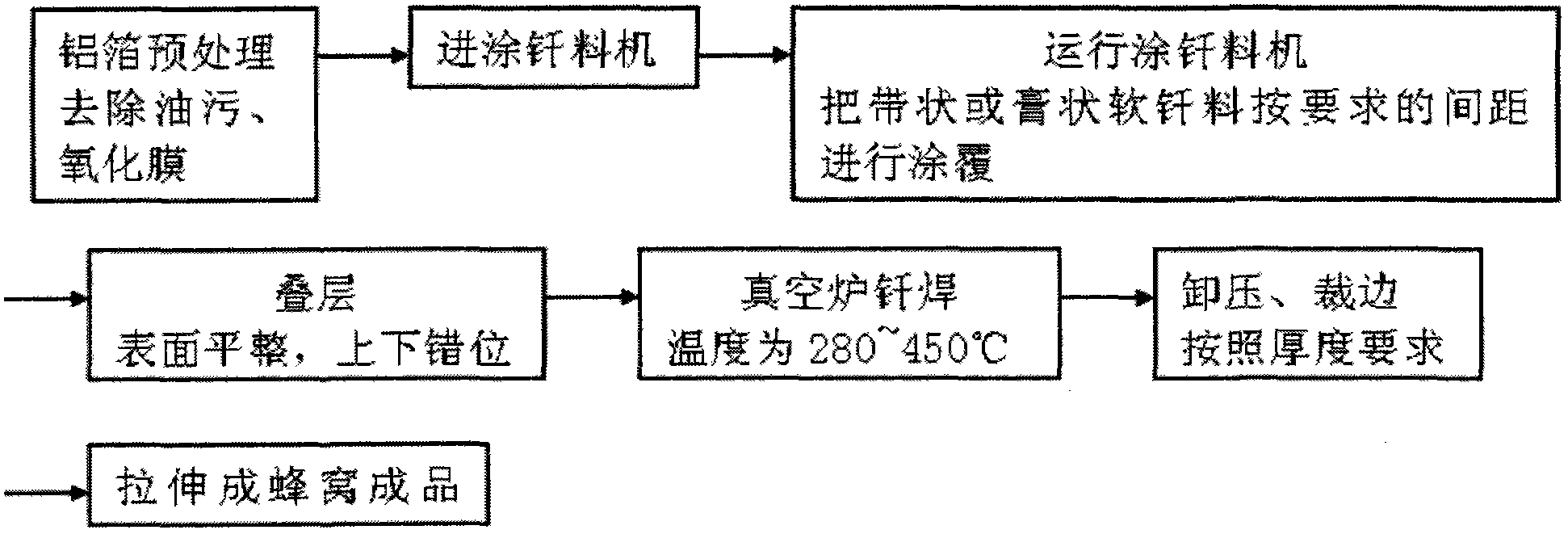

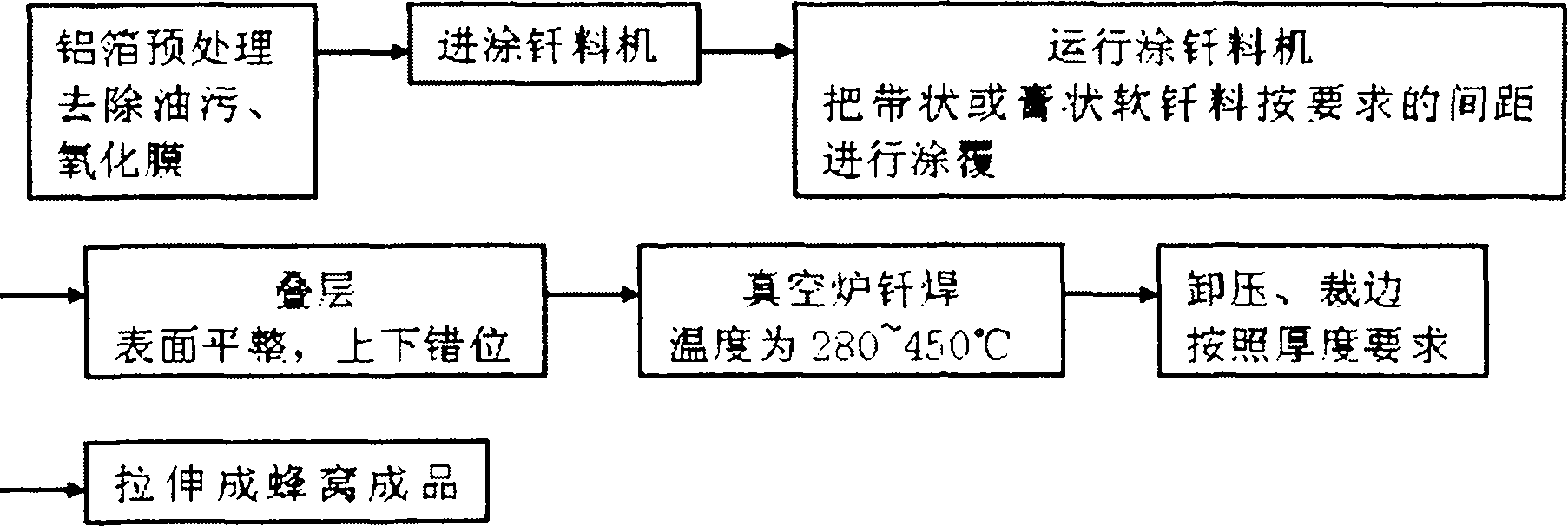

[0029] see figure 1 As shown, the preparation method of the aluminum honeycomb core material of the present invention is to prepare the aluminum honeycomb core material by soldering with solder, and the aluminum honeycomb core material is prepared by soldering:

[0030] a. Aluminum foil pretreatment to remove oil and oxide film;

[0031] b. Into the brazing filler metal machine;

[0032] c. Run the solder coating machine to coat the ribbon or paste solder according to the required spacing;

[0033] d. Lamination, smooth surface, dislocation up and down;

[0034] e. Vacuum furnace brazing, the temperature is 280 to 450 degrees;

[0035] f, pressure relief, edge trimming, according to the thickness requirements;

[0036] g. Stretching into honeycomb finished products.

[0037] Wherein, the material of the soldering is resin (containing rosin), of course, the soldering can also be inorganic (containing acid additives) flux, the heating temperature of the solder is 280 degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com