Automatic pressing forming device and method of low-pressure casting sprue filter net

A low-pressure casting and forming device technology, applied to online nets, other home appliances, home appliances, etc., to achieve the effects of improving operational safety, overcoming differences, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

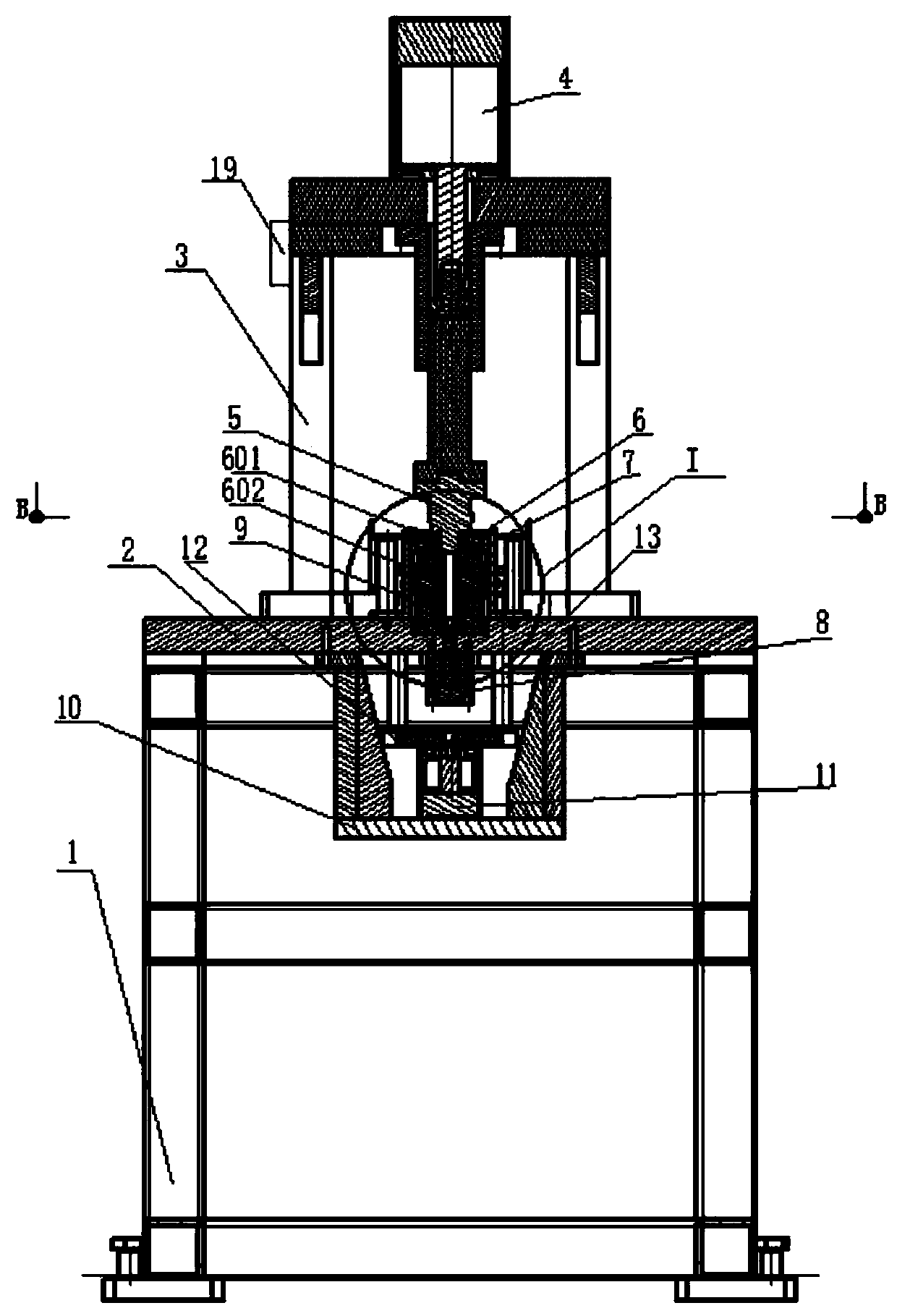

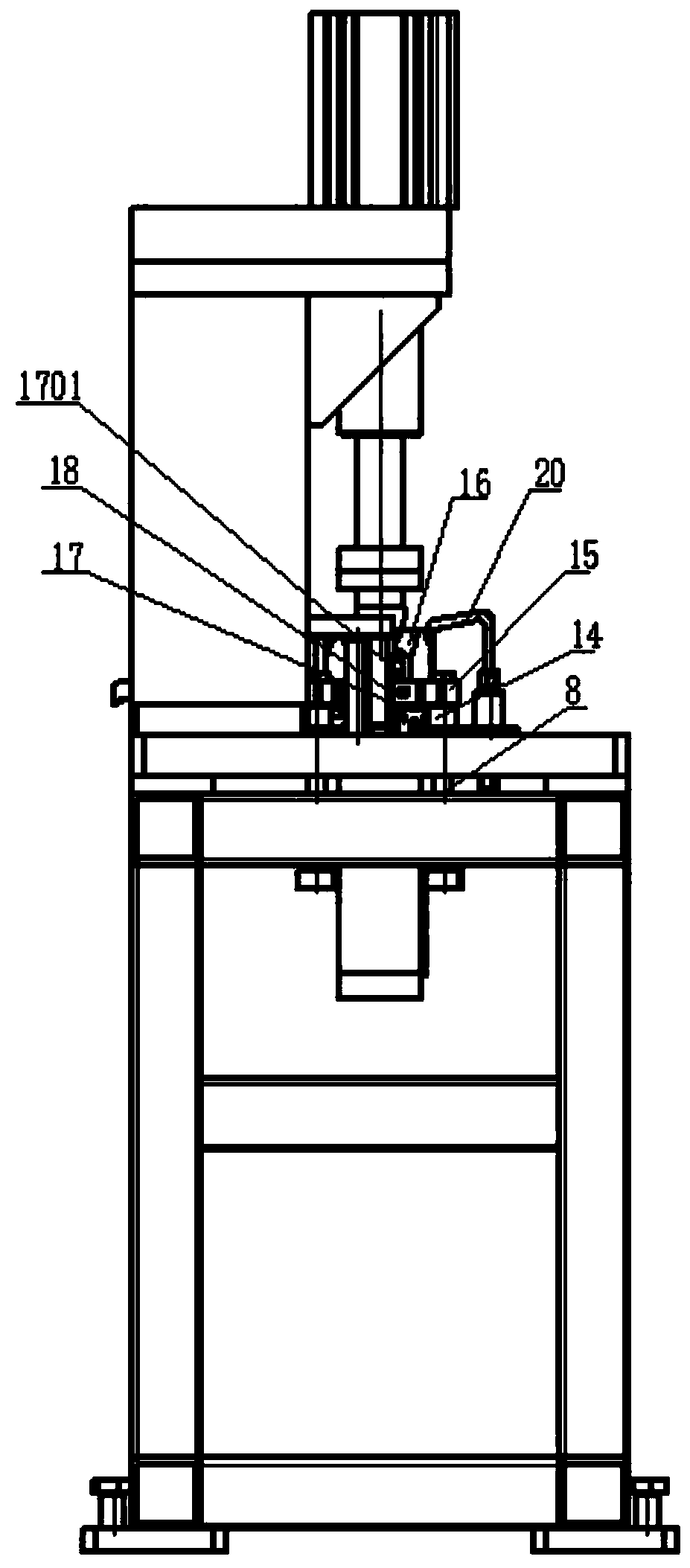

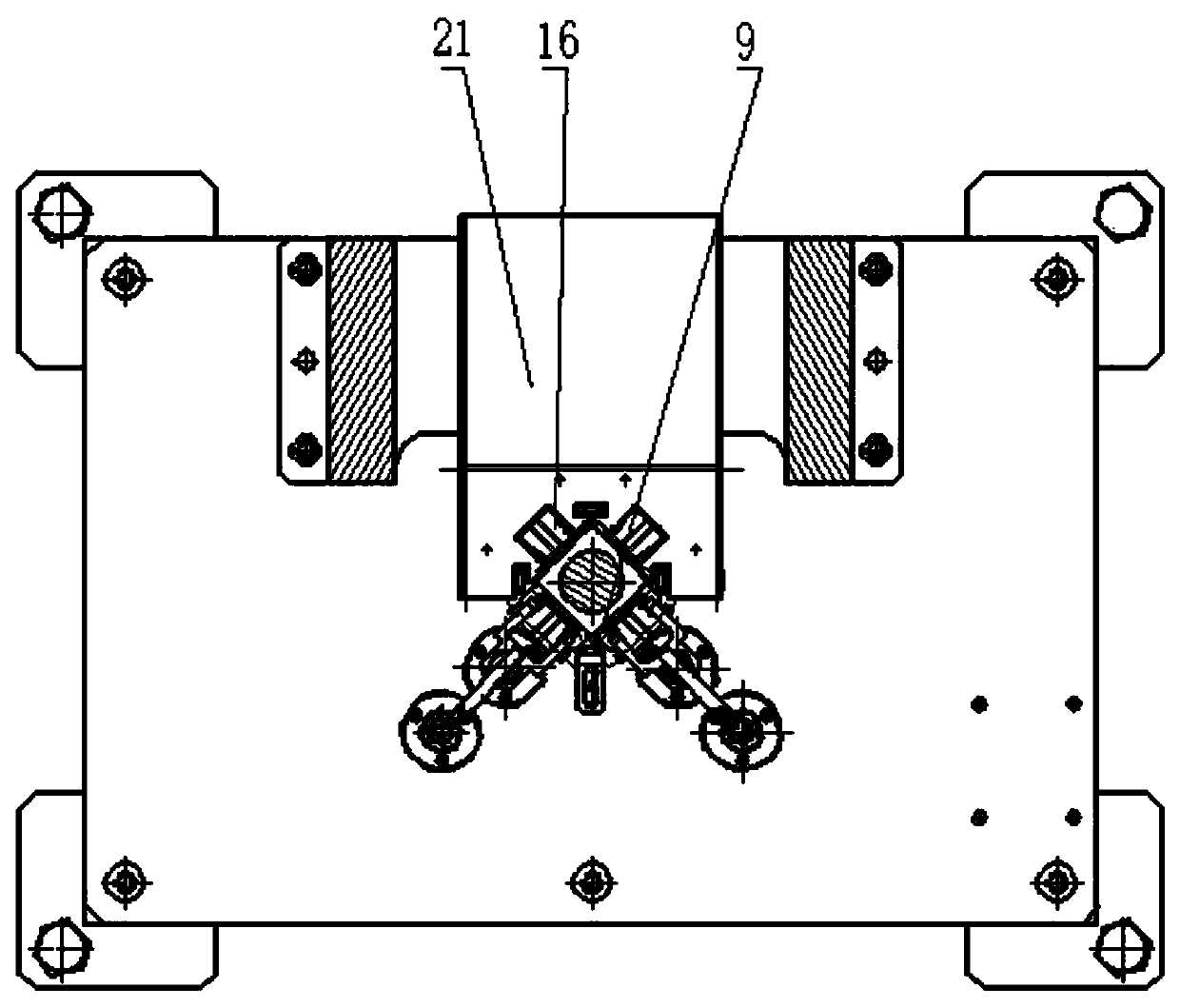

[0034] Such as Figure 1 to Figure 3 The automatic press-forming device for the low-pressure casting gate filter net shown includes a base 1 and a bottom plate 2 fixed on the top of the base 1. The rear end of the bottom plate 2 is fixedly installed with a first mount 3. The molding device also includes a one-time molding structure, overmolding structure and PLC control system 19,

[0035] The primary molding structure includes a first cylinder 4 fixed vertically on the first mounting base 3, the lower end of the first cylinder 4 is fixedly connected to the upper mold 5; Forming cavity 601 and cavity 602 are vertically arranged in the mold 6, and forming cavity 601 is located at the top of cavity 602. In order to ensure that the filter screen is qualified for one-time molding and pressing, the axes of the upper mold 5 and the lower molding mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com