Ultra-short-focus anti-light projection curtain and preparation method thereof

A projection screen and ultra-short-focus technology, which is applied in the field of projection display, can solve the problems of high product price, high difficulty, and low yield rate of ultra-short-focus anti-light projection screens, and achieve high yield rate, low production cost, and regular structure beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

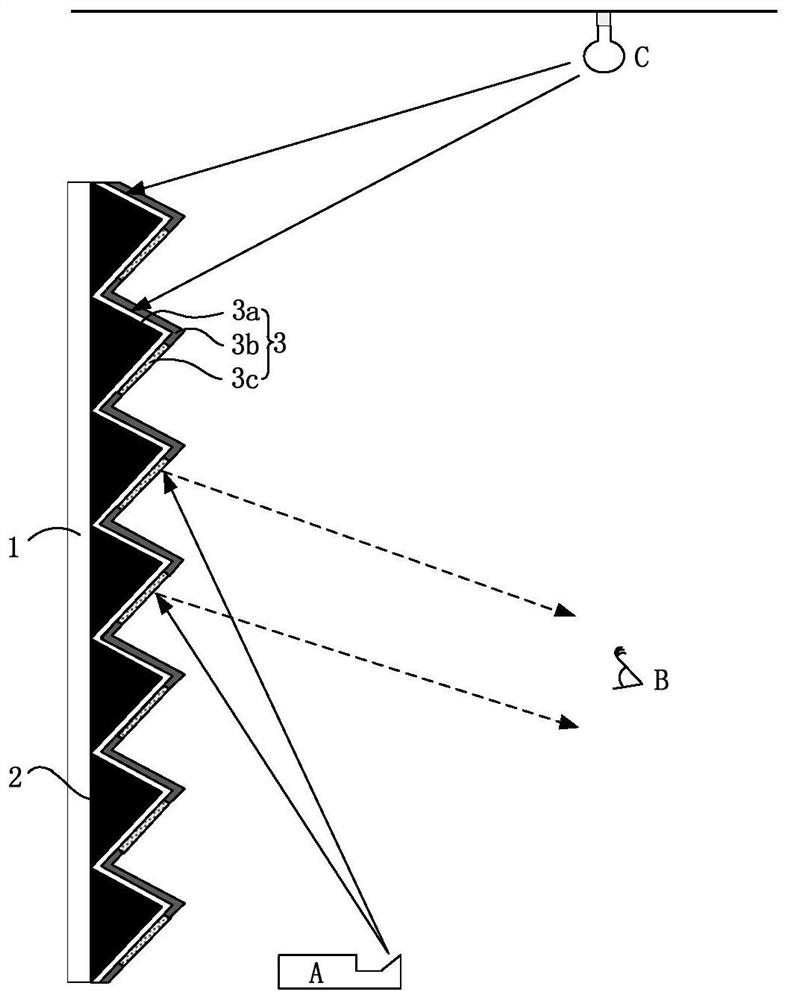

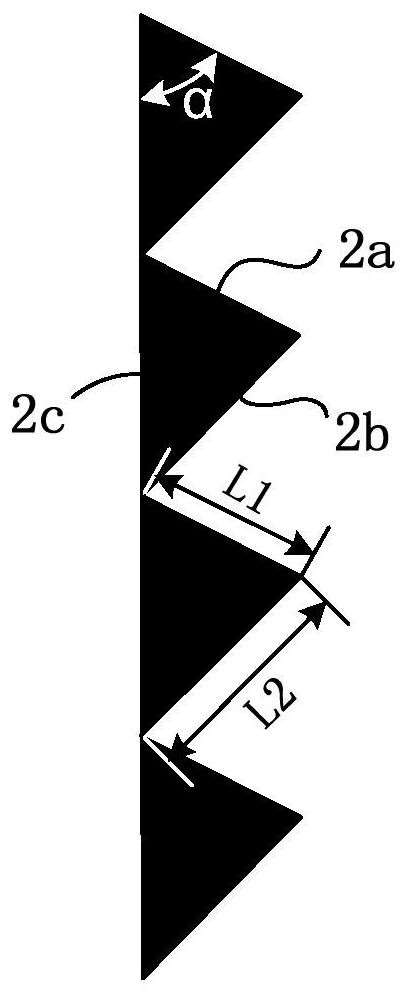

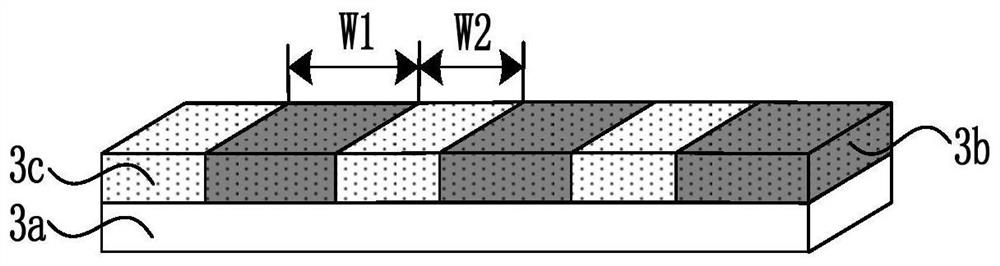

[0059] refer to figure 1 , The ultra-short-focus anti-light projection screen includes: a bottom layer 1, an optical prism layer 2 and a surface layer 3. Wherein, the optical prism layer 2 is formed on at least part of the surface of the bottom layer 1; the optical prism layer 2 is formed by arranging a plurality of optical prism units whose horizontal section is triangular, and the optical prism unit includes an upper side 2a, a lower side 2b and a bottom 2c , the bottom surface 2c is arranged on the bottom layer 1; the surface layer 3 is formed on at least part of the surface of the optical prism layer 2 away from the bottom layer 1; the surface layer 3 includes a support layer 3a, and is formed on the support layer 3a. The light-absorbing stripes 3b and the white reflective stripes 3c are arranged alternately with the black light-absorbing stripes 3b and the white reflective stripes 3c, and the white reflective stripes 3c are located on the support layer 3a attached to the ...

Embodiment 2

[0061] refer to Figure 4 , The ultra-short-focus anti-light projection screen includes: a bottom layer 21 , an optical prism layer 22 and a surface layer 23 . Wherein, the surface layer 23 includes a support layer 23a, and white reflective stripes 23c formed on at least part of the surface of the support layer 23a away from the optical prism layer 22, the white reflective stripes 23c are located on the support layer 23a attached to the lower side of the optical prism layer 22 superior. Other structural features of the ultra-short-focus anti-light projection screen are the same as in Embodiment 1.

[0062] The surface layer 23 of the ultra-short-focus anti-light projection screen has only white reflective stripes 23c and no black light-absorbing stripes 23b, and the light transmittance of the support layer 23a is greater than or equal to 95%, which is beneficial to the ambient light above the anti-light projection screen through the support layer 23a Absorbed by the optical ...

Embodiment 3

[0064] refer to Figure 5, The ultra-short-focus anti-light projection screen includes: a bottom layer 31 , an optical prism layer 32 and a surface layer 33 . Wherein, the surface layer 33 includes a support layer 33a, and black light absorption stripes 33b and white reflective stripes 33c formed on at least part of the surface of the support layer 33a away from the optical prism layer 32, and the white reflective stripes 33c are located on the lower side of the optical prism layer 32 on the attached support layer 23a. The bottom layer 31 is black opaque material. Other structural features of the ultra-short-focus anti-light projection screen are the same as in Embodiment 1.

[0065] The bottom layer 31 of the ultra-short-focus anti-light projection screen is black opaque material, which can be used as the first light absorption mechanism to absorb the ambient light on the back of the anti-light projection screen. With the optical prism layer 32, the double-layer light absor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com