Intermediate temperature self-reaction brazing method for aluminum honeycomb boards

A technology of aluminum honeycomb and honeycomb panels, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Dissolve the base metal and other problems, achieve the effects of easy realization, high temperature aging resistance and other performance improvements, and avoid the difficulty of presetting the solder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

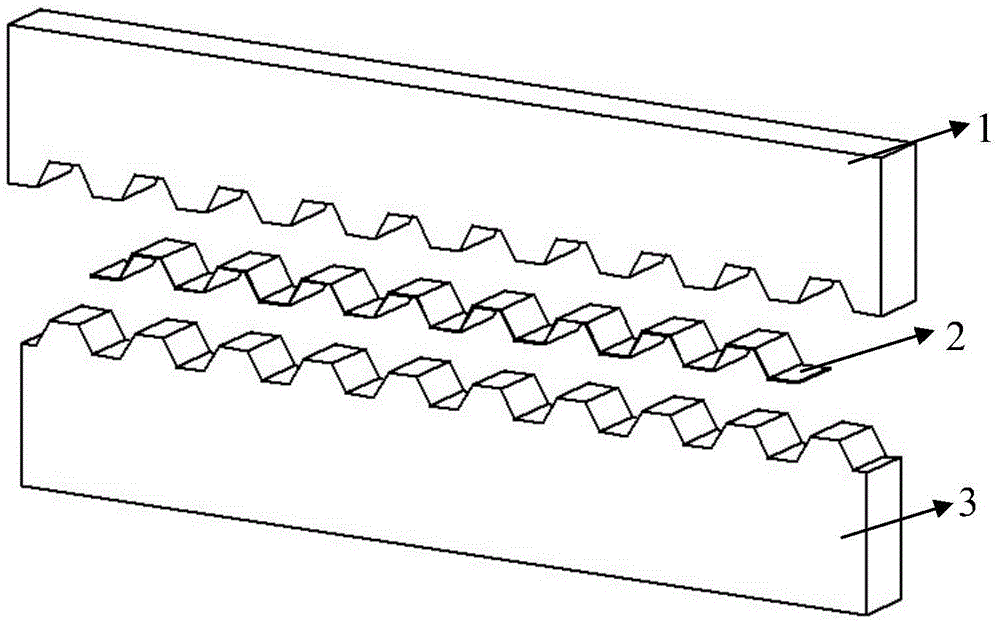

[0041] Aluminum honeycomb panels were prepared by brazing with 1mm thick 3003 aluminum alloy as the panel and 0.2mm thick composite aluminum foil (3003 aluminum alloy as the core material and 4045 aluminum alloy as the cladding layer) as the honeycomb core.

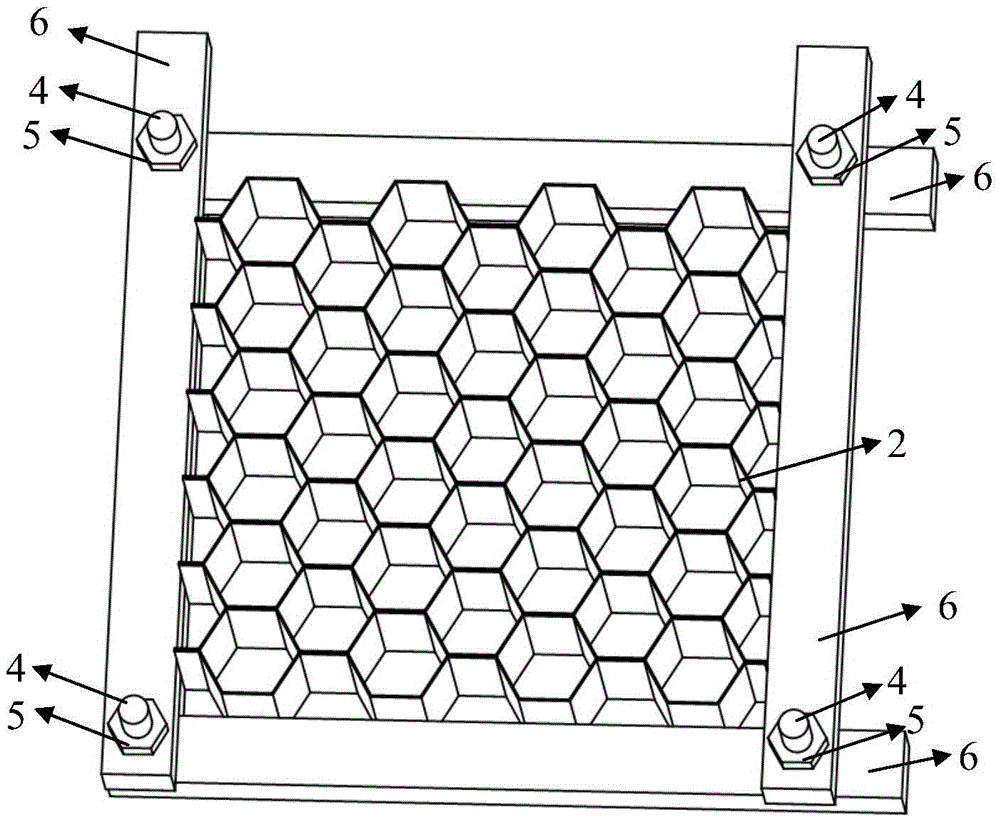

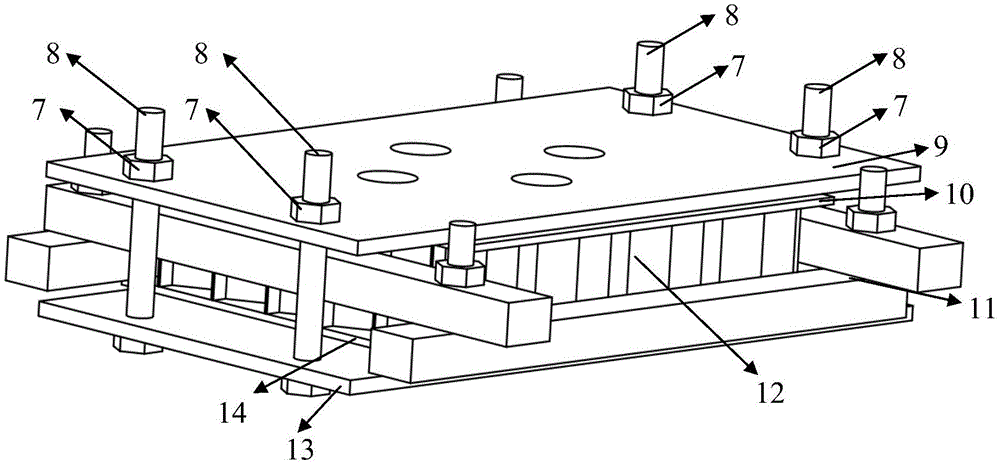

[0042] 1) Make the aluminum honeycomb core fixture, process the stainless steel plate into four frame bars, such as figure 2 The aluminum honeycomb core fixture frame bar 6 shows that the length, width, and thickness of the frame bar are: 90mm×8mm×6mm, and an M2 threaded hole is opened at both ends of each frame bar, and the distance between the two threaded holes is 76mm to ensure that the center of the fixture The size of the aluminum honeycomb core that can be fixedly assembled is 68mm×68mm. use figure 2 Bolts 4 for fixing the aluminum honeycomb core fixture and nuts 5 for fixing the aluminum honeycomb core fixture connect and fix the four frame bars end to end in sequence, that is, they are assembled into an alumin...

Embodiment 2

[0050] Example 2: Brazing Prepare an aluminum honeycomb panel with a 1.5mm thick composite brazing plate, a core material of 3003 aluminum alloy, a cladding layer of 4043 aluminum alloy as a panel, and a 0.15mm thick 1060 aluminum foil as a honeycomb core. The specific preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com