Method for designing and manufacturing ventilation channel of honeycomb sandwich structure

A technology of a honeycomb sandwich layer and a manufacturing method is applied in the field of design and manufacture of ventilation channels of a honeycomb sandwich structure, and can solve the problems of debonding and structural damage of the honeycomb sandwich core and the glass fiber reinforced plastic skin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

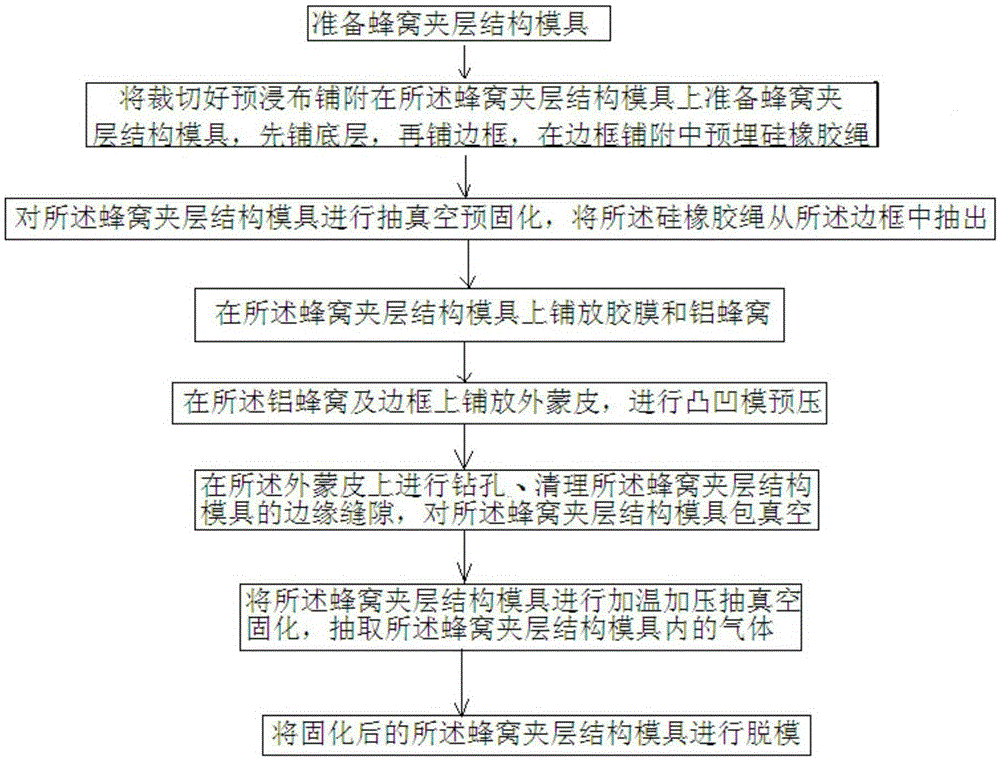

[0018] see figure 1 A method for designing and manufacturing a honeycomb sandwich structure ventilation channel provided by an embodiment of the present invention includes the following steps:

[0019] Step 1, prepare the honeycomb sandwich structure mold.

[0020] Step 2: Lay the cut prepreg cloth on the honeycomb sandwich structure mold, first lay the bottom layer, then lay the frame, and pre-embed the silicone rubber rope in the frame laying attachment.

[0021] Step 3, performing vacuum pre-curing on the honeycomb sandwich structure mold, and pulling out the silicone rubber rope from the frame.

[0022] Step 4, laying the adhesive film and the aluminum honeycomb on the honeycomb sandwich structure mould.

[0023] Step 5, laying the outer skin on the aluminum honeycomb and the frame, and pre-pressing the convex and concave molds.

[0024] Step 6, drilling holes on the outer skin, cleaning the edge gaps of the honeycomb sandwich structure mold, and vacuuming the honeycomb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com