Effective SCR (selective catalytic reduction) catalyst applied to purification of nitrogen oxide in tail gas of diesel engine

A technology of SCR catalyst and nitrogen oxide, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical/physical process, etc., and can solve the problems of high temperature thermal stability and low temperature poor activity , to achieve the effects of improving thermal stability and durability, prolonging service life, and improving low-temperature reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The catalyst consists of three parts: carrier, composite oxide base coating and active components. The carrier is cordierite honeycomb ceramics with a volume of 6.7L and a mesh number of 300 mesh. The complex oxide base coat contains titanium, tungsten, silicon and zirconium oxides. The active components contain vanadium, manganese and copper oxides. Catalyst preparation steps are as follows:

[0027] (1) Raw material dispersion of the composite oxide base coating: take the composite oxide base coating raw material, which includes nano anatase titanium dioxide powder, ammonium metatungstate, silica sol and zirconium acetate. According to the composite oxide base coating material: water mass ratio is 1:4, add 5% Tween 80 relative to the mass of the mixed solution, and then place the above mixed solution in an ultrasonic environment for ultrasonic dispersion for 2 hours, and the ultrasonic frequency is 40kHz. The quality of the nano-anatase titanium dioxide powder is 9...

Embodiment 2

[0036] The specific preparation steps and activity test of the catalyst are basically the same as in Example 1, except that in the preparation of the active component solution, the mass of the respective oxides corresponding to manganese nitrate, copper nitrate and ammonium metavanadate is respectively the mass of the prepared active component solution. 0%, 15% and 85% of the mass.

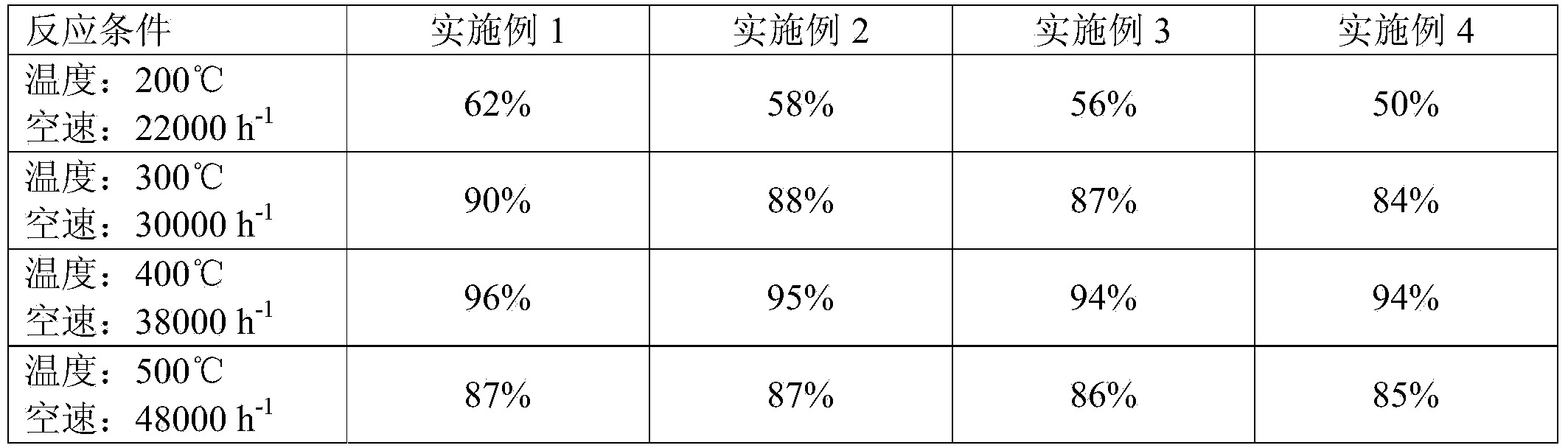

[0037] The catalyst activity test results are shown in Table 1.

Embodiment 3

[0039] The specific preparation steps and activity test of the catalyst are basically the same as in Example 1, except that in the preparation of the active component solution, the mass of the respective oxides corresponding to manganese nitrate, copper nitrate and ammonium metavanadate is respectively the mass of the prepared active component solution. 15%, 0% and 85% of the mass.

[0040] The catalyst activity test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com