Ceramic crystal coating for metal surfaces and preparation method thereof

A metal surface and coating technology, applied in the direction of coating, etc., can solve the problems of suffocation and death, affecting the durability and stain resistance of fluorocarbon coatings, and achieve the effects of good durability, long construction period and excellent stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Aluminum alloy curtain wall light blue ceramic coating formula

[0042]

[0043] The preparation method of light blue ceramic crystal coating for aluminum alloy curtain wall is as follows:

[0044]Step 1. In the batching tank, add the raw materials of organic modifier, wetting and dispersing agent and ethylene glycol ether acetate in sequence according to the weight fraction, and mix evenly;

[0045] Step 2. Slowly add titanium dioxide (TS-6200), fumed silica and cobalt blue into the batching tank according to the weight fraction and disperse evenly, and then use a sand mill to grind to a fineness of ≤25um;

[0046] Step 3, add aluminum silicate sol and isopropanol paint in turn, mix well;

[0047] Finally, after degreasing and degreasing the aluminum plate, use 120-mesh corundum for sandblasting, then use high-pressure air to remove dust, mix the paint evenly and then spray it. The thickness of the paint film is controlled at 20-30um.

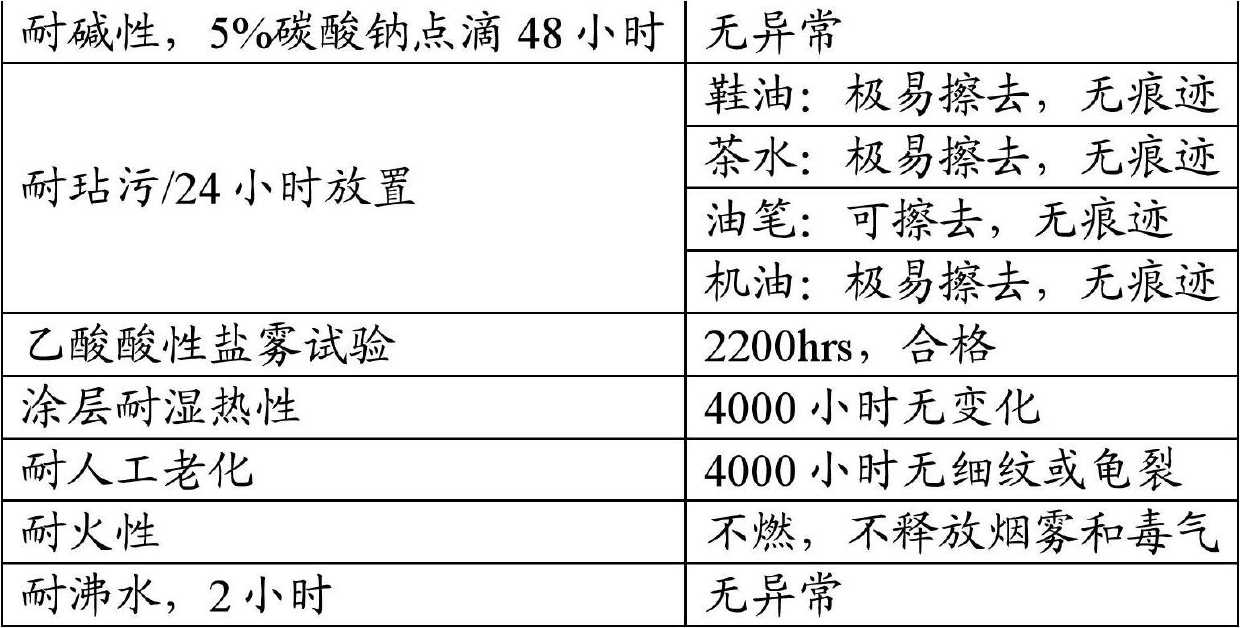

[0048] The performance of t...

Embodiment 2

[0053] Aluminum alloy curtain wall light blue ceramic coating formula

[0054]

[0055] The preparation method of light blue ceramic crystal coating for aluminum alloy curtain wall is as follows:

[0056] Step 1. In the batching tank, add the raw materials of organic modifier, wetting and dispersing agent and ethylene glycol ether acetate in sequence according to the weight fraction, and mix evenly;

[0057] Step 2. Slowly add titanium dioxide (TS-6200), fumed silica and cobalt blue into the batching tank according to the weight fraction and disperse evenly, and then use a sand mill to grind to a fineness of ≤25um;

[0058] Step 3, add aluminum silicate sol and isopropanol paint in turn, mix well;

[0059] Finally, after degreasing and degreasing the aluminum plate, use 120-mesh corundum for sandblasting, then use high-pressure air to remove dust, mix the paint evenly and then spray it. The thickness of the paint film is controlled at 20-30um.

[0060] The performance of ...

Embodiment 3

[0064] Aluminum alloy curtain wall light blue ceramic coating formula

[0065]

[0066]

[0067] The preparation method of light blue ceramic crystal coating for aluminum alloy curtain wall is as follows:

[0068] Step 1. In the batching tank, add the raw materials of organic modifier, wetting and dispersing agent and ethylene glycol ether acetate in sequence according to the weight fraction, and mix evenly;

[0069] Step 2. Slowly add titanium dioxide (TS-6200), fumed silica and cobalt blue into the batching tank according to the weight fraction and disperse evenly, and then grind with a sand mill until the fineness is ≤25um;

[0070] Step 3, add aluminum silicate sol and isopropanol paint in turn, mix well;

[0071] Finally, after degreasing and degreasing the aluminum plate, use 120-mesh corundum for sandblasting, then use high-pressure air to remove dust, mix the paint evenly and then spray it. The thickness of the paint film is controlled at 20-30um.

[0072] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com