Collapsing and unfolding support tubes for space membrane facilities

A space film and support tube technology, which is used in space navigation equipment, space navigation equipment, space navigation aircraft, etc., can solve the problems of low deployment stability and reliability, large launch volume, and low collection efficiency, and achieve deployment High reliability, small storage volume and high collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

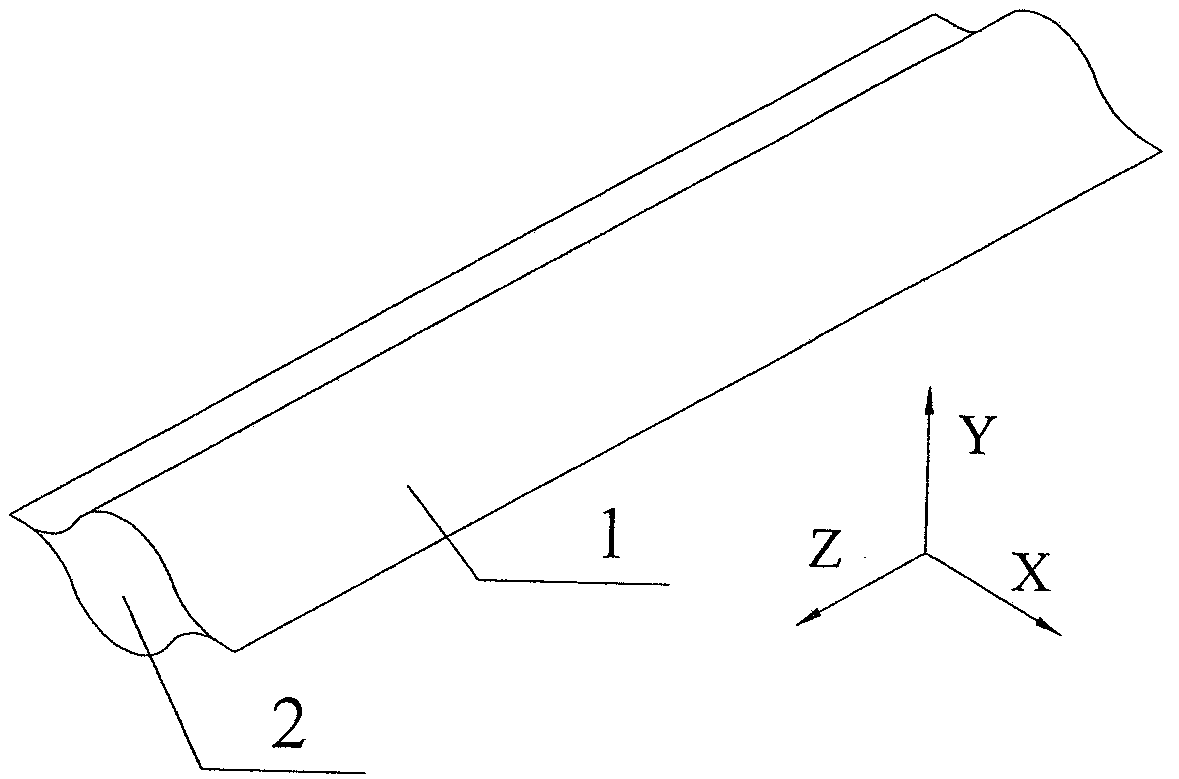

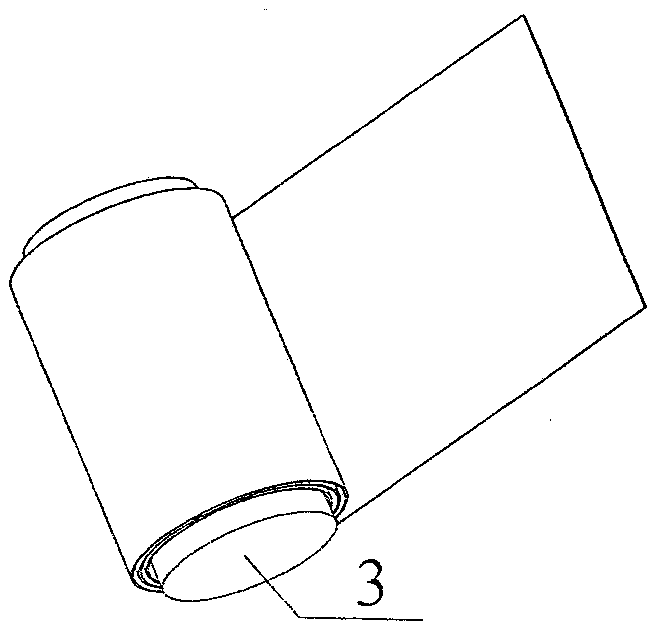

[0016] figure 1 It is the configuration in the stretched state of the folded and unfolded support tube of the space film facility of the present invention, such as figure 1 In the illustrated embodiment, the device includes:

[0017] The upper thin-walled shell 1 and the lower thin-walled shell 2 with a cross-section in the shape of "Ω", the semicircular concave surfaces in the middle of the upper thin-walled shell 1 and the lower thin-walled shell 2 are facing each other, and the planar edges on both sides correspond to each other Glue to form a pod-shaped thin-walled support pipe with a length of 0.5-30m.

[0018] The cross-sections of the upper thin-walled housing 1 and the lower thin-walled housing 2 can also be formed by tangential arcs of multiple segments, the edge of the thin-walled housing is planar, and the upper thin-walled housing 1 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com