Carbon-fibre composite boom for concrete pump truck

A technology for concrete pump trucks and composite materials, which is applied in the processing of building materials, construction, and building construction. It can solve problems such as heavy weight, poor mobility, and corrosion, and achieve high specific modulus, superior performance, and high specific strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

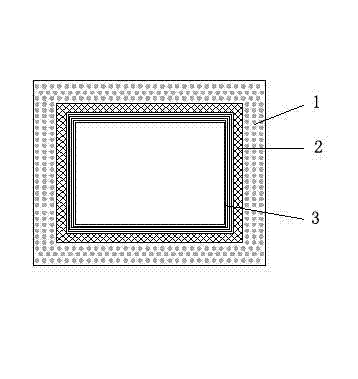

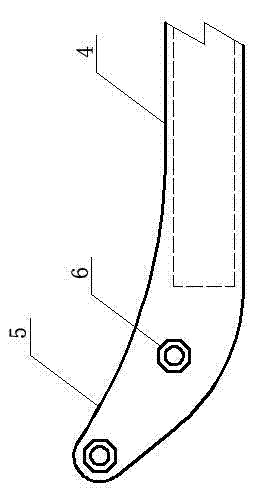

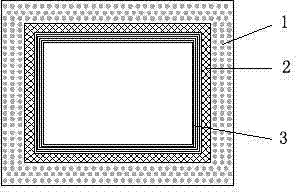

[0015] Such as figure 1 , figure 2 As shown, the present invention is provided with a main body box girder 4, the inner layer of the main body box girder 4 is covered with a carbon fiber cloth prepreg 3 at an angle of 90°, and the middle layer of the main body box girder 4 is covered with ±45° angle carbon fiber Cloth prepreg 2, the outer layer of the main box beam 4 is covered with carbon fiber cloth prepreg 1 at an angle of 0°, the root of the main box beam 4 is provided with a splint 5 connected as a whole, and the splint 5 has pins on it Holes, pin holes are inlaid with wear-resistant metal bushings 6, the inside of the metal bushing 6 is a circular hole, and the outside is a square or a regular hexagon or a regular octagon. The manufacturing process of this embodiment is as follows: firstly pave the mandrel with a 90° angle carbon fiber cloth prepreg, or wrap a 0° angle carbon fiber cloth prepreg with a smaller width on the mandrel at a smaller pitch, Lay to the requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com